WE866E4-P Module Hardware User Guide

1VV0301487 Rev. 1.2 39 2018-07-27

PRELIMINAR

Y

9.3.1 Recommendations for PCB Pad Surface

Table 17, page 39 provides the recommendation for PCB Pad Surface.

The PCB must be able to resist higher temperatures which occurs at the lead-free process.

This issue should be discussed with the PCB supplier. Generally, the wettability of tin-lead

solder paste on the described surface plating is better compared to lead-free solder paste.

It is not necessary to panel the application PCB, however it is suggested to use milled

contours and pre-drilled board breakouts. Scoring or v-cut solutions are not recommended.

9.4 Stencil

Stencil’s apertures layout can be the same of the recommended footprint (1:1), a thickness

of stencil foil ≥ 120 μm is suggested.

9.5 Solder Paste

It is recommended to use only “no clean” solder paste in order to avoid the cleaning of the

modules after assembly. The lead-free solder paste is Sn/Ag/Cu.

9.6 Solder Re-flow

Figure 11, page 40 shows the recommended solder profile re-flow:

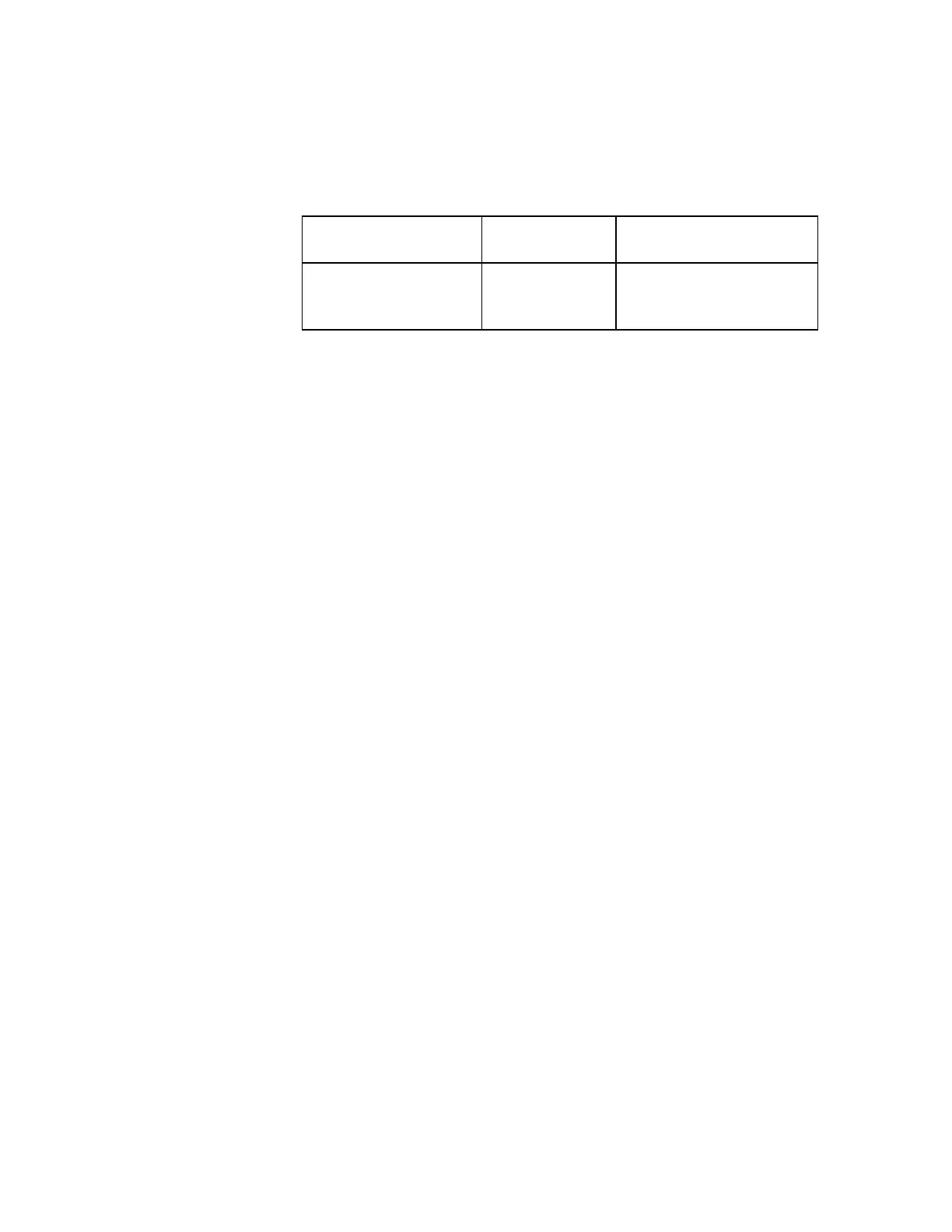

Table 17 Recommendation for PCB Pad Surface

Finish Layer Thickness

(um)

Properties

Electro-less

Ni/Immersion Au

3 - 7/ 0.03 - 0.15

Good solderability

protection, high shear force

values

Loading...

Loading...