Section 3 - Step-By-Step Assembly

Temp-Cast 2000 Installation Manual

10

SECTION 3: STEP-BY-STEP ASSEMBLY

ASSEMBLY NOTES

1. Dry-assemble the heater upon

delivery, to check the condition of all

parts and to familiarize yourself with

the modules. (If all of the parts are not

numbered, you may find it helpful to do

so, using this manual, before taking

the unit apart again.)

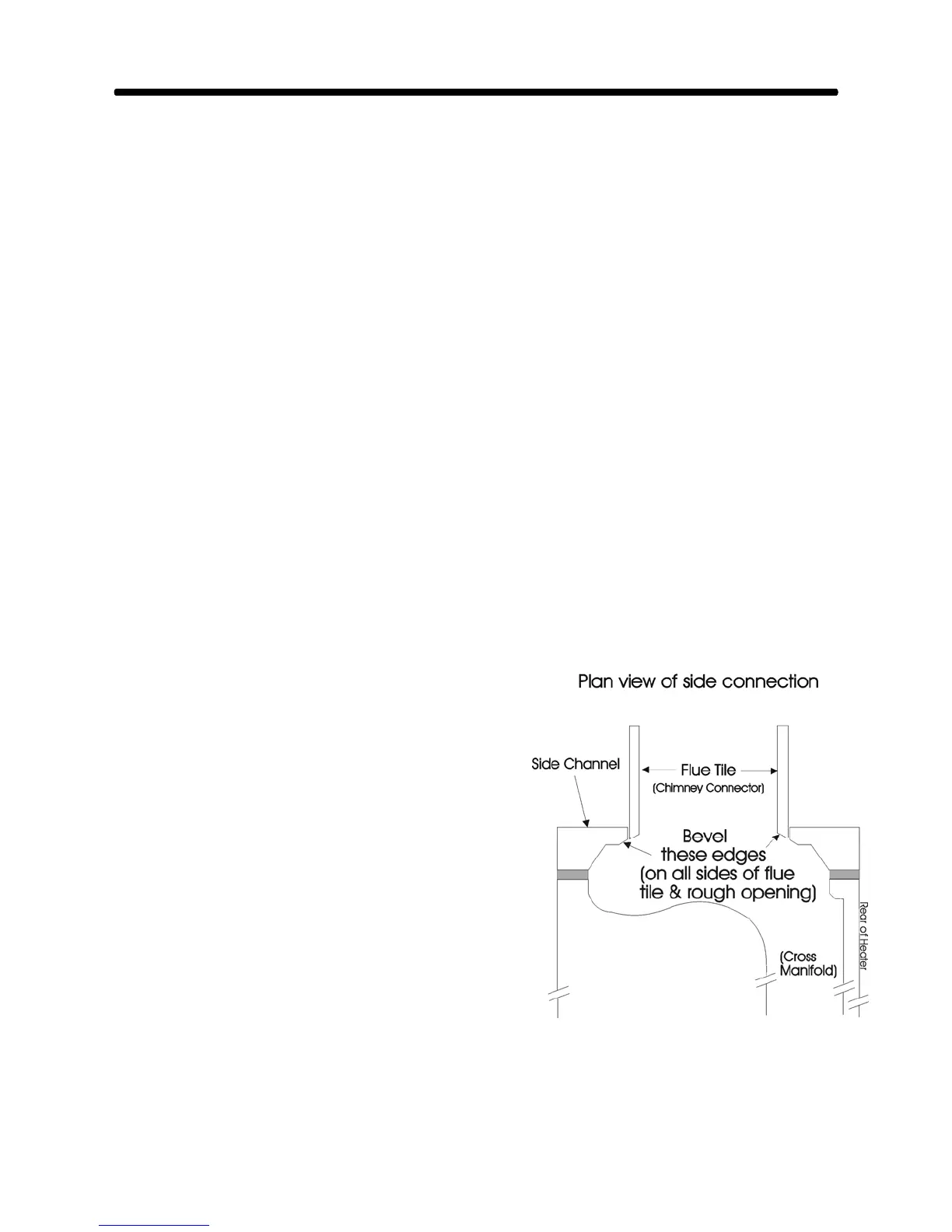

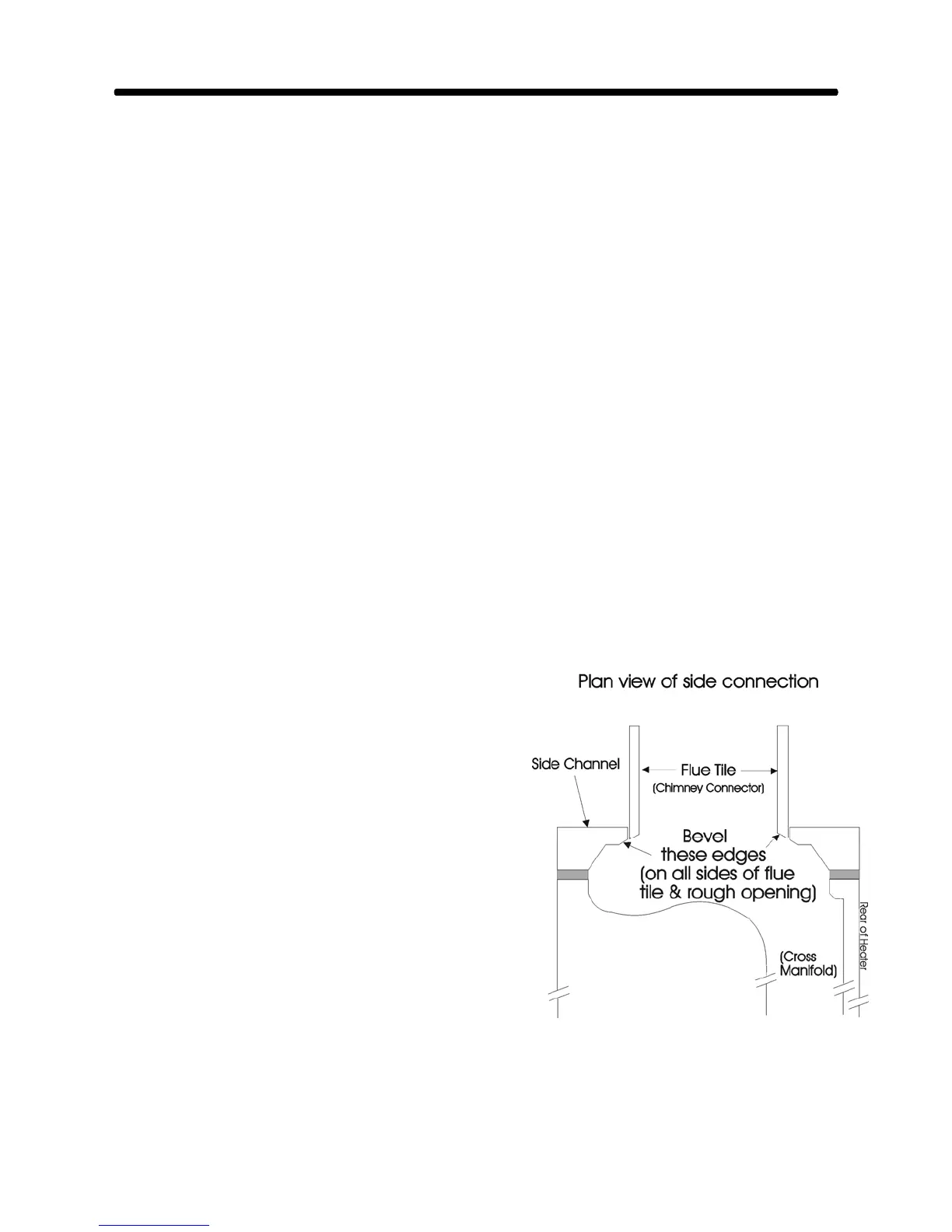

2. Cutting of flue tiles and fireplace

modules should be done outdoors due

to the excessive dust created. WEAR

SUITABLE EAR, EYE AND LUNG

PROTECTION.

3. A 4” grinder with a diamond blade is

best for cutting holes in flue tiles and

fireplace modules. Or round holes can

be cut as six or eight-sided shapes

with a gas, water or circular saw or

drilled every inch (25mm) and then cut

with a reciprocating saw fitted with a

masonry blade. Rounding or beveling

the inside edges of the hole in the

module creates the least resistance to

the flow of smoke and gases,

maximizing draft and performance.

(See Fig. 8)

4. When using the ceramic-fibre gasket

material, it should only be slightly

compressed. Compressing it too

much will defeat its purpose as an

expansion gasket. (A small amount of

refractory mortar can be used to

cement the gasket in position.)

5. Refractory casting occasionally leaves

behind rough spots or small bumps on

the modules. If these rough spots

should occur in a joint between 2

modules, they may prevent a tight joint

and make installation of subsequent

parts more difficult. Remove any such

bumps with a rasp or scraping tool

before assembling.

6. Refractory mortar should be used

sparingly, applying a small (1/4” to

3/8”) bead between modules. The

finished joint should have a very thin

skin of refractory mortar, which is the

strongest. (In addition, the parts will

only fit properly if the thinnest possible

joint is created.) Apply a small amount

on the outside edges of the part, where

indicated by the shaded areas. Do not

use a full bed of mortar. Seat the

parts completely, using a rubber

mallet, so that a little mortar squeezes

out. After each course, scrape off and

save excess mortar for possible later

use. Periodically wipe the modules

inside and out with a damp sponge to

ensure that excess mortar has not

been left behind.

Fig. 8

Loading...

Loading...