Section 2 – Chimneys & Dampers

Temp-Cast 2000 Installation Manual February 2010

7

Fig 3

A 4” grinder with a diamond blade is ideal for

cutting accurate & neat holes in the refractory

concrete modules.

FACTORY-BUILT CHIMNEYS

We do not recommend exterior chimneys, (see

Sec. 4 of the Temp-Cast Planning Guide) but if a

chimney on the outside of the house is

unavoidable, then an insulated factory-built (e.g.

"HT" or 2100F.) chimney is the better choice.

When a factory-built chimney is started at the

floor level, there will not be sufficient space to

access the clean-out cap under it. In order to

provide a clean out access, one of the following

2 methods is suggested.

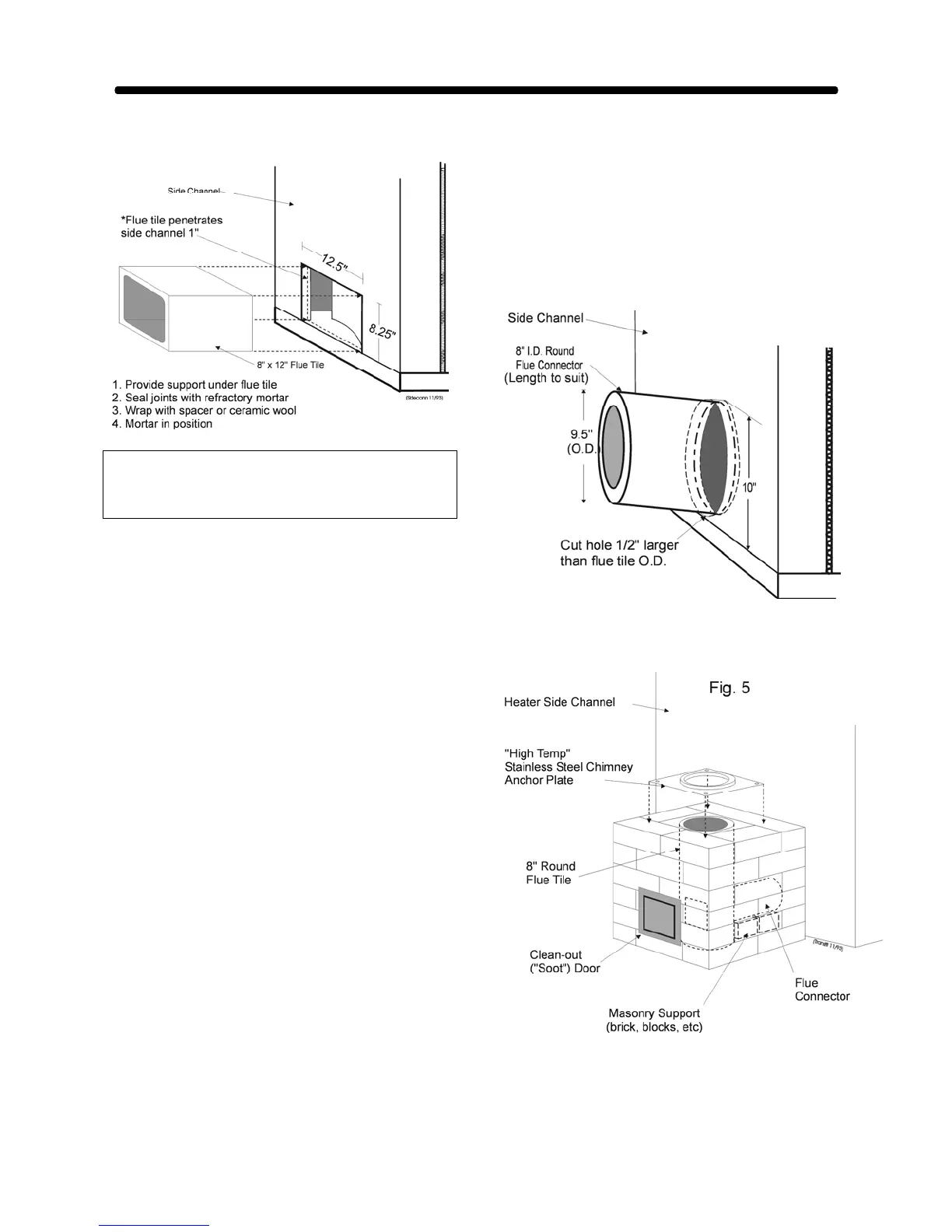

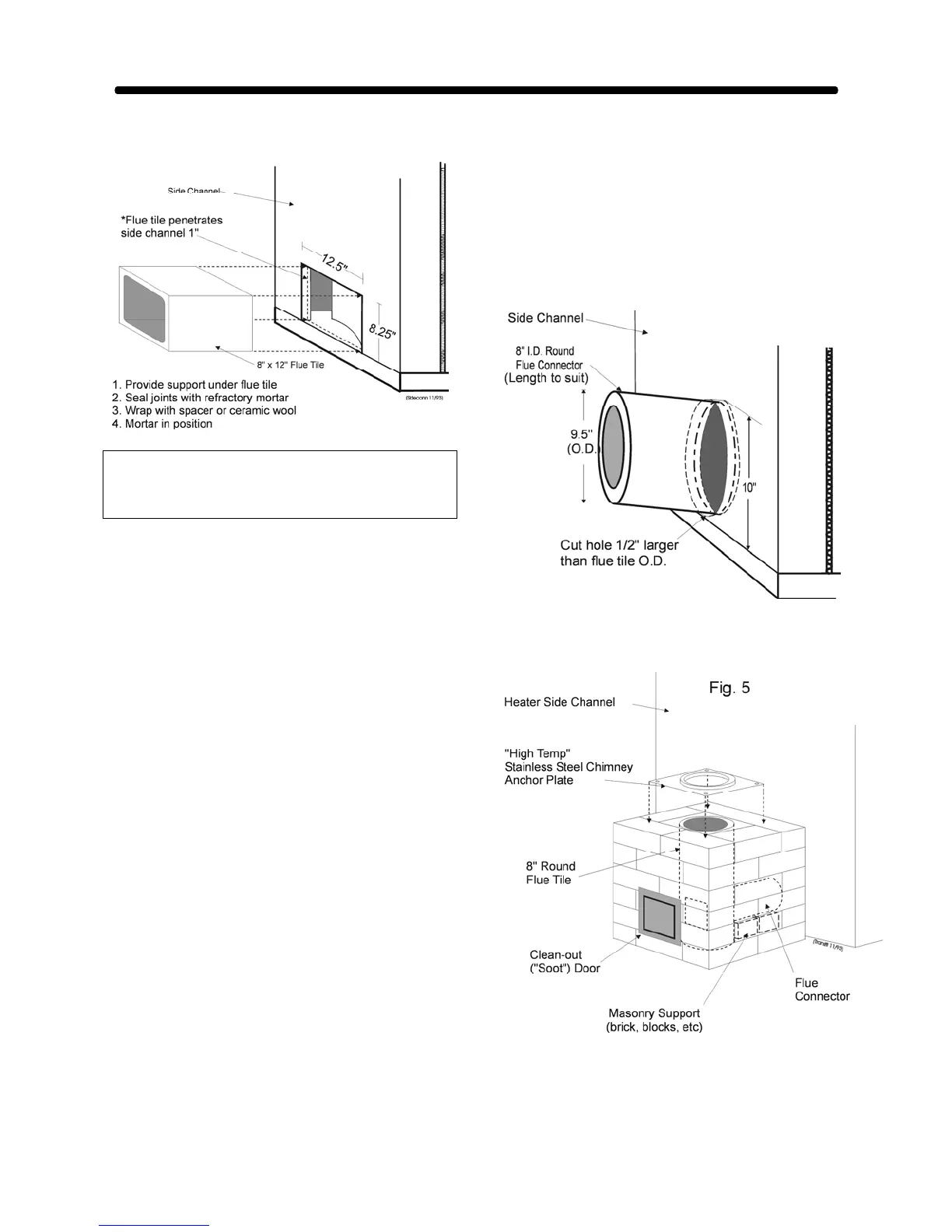

Create a masonry connection to the fireplace,

with 8" (200mm) round flue tile. Add vertical

sections of 8” round flue tile, with a clean-out

access built into the first vertical section. Wrap

the horizontal tile and the first vertical flue tile

with “ceramic wool” blanket & ensure they

cannot be dislodged. Continue with flue tile &

masonry to the point where the transition to

factor-built chimney is wanted – often the

masonry is extended to the first ceiling. If a

roof-top damper is to be installed, the cable

protector for the damper cable must be built into

the masonry chimney where it will be accessible

for daily use – we recommend at least 6 feet

from the floor. Install an anchor plate approved

for the factory-built chimney, on top of the last

masonry section - the factory-built chimney

continues from this point. (See Fig. 5.) If the

factory-built chimney will also be enclosed in

masonry, the layout of the first masonry courses

must take this into account. (Confirm this

connection method with your local building

official.)

Fig 4

Loading...

Loading...