Section 1 - Introduction

Temp-Cast 2000 Installation Manual February 2010

5

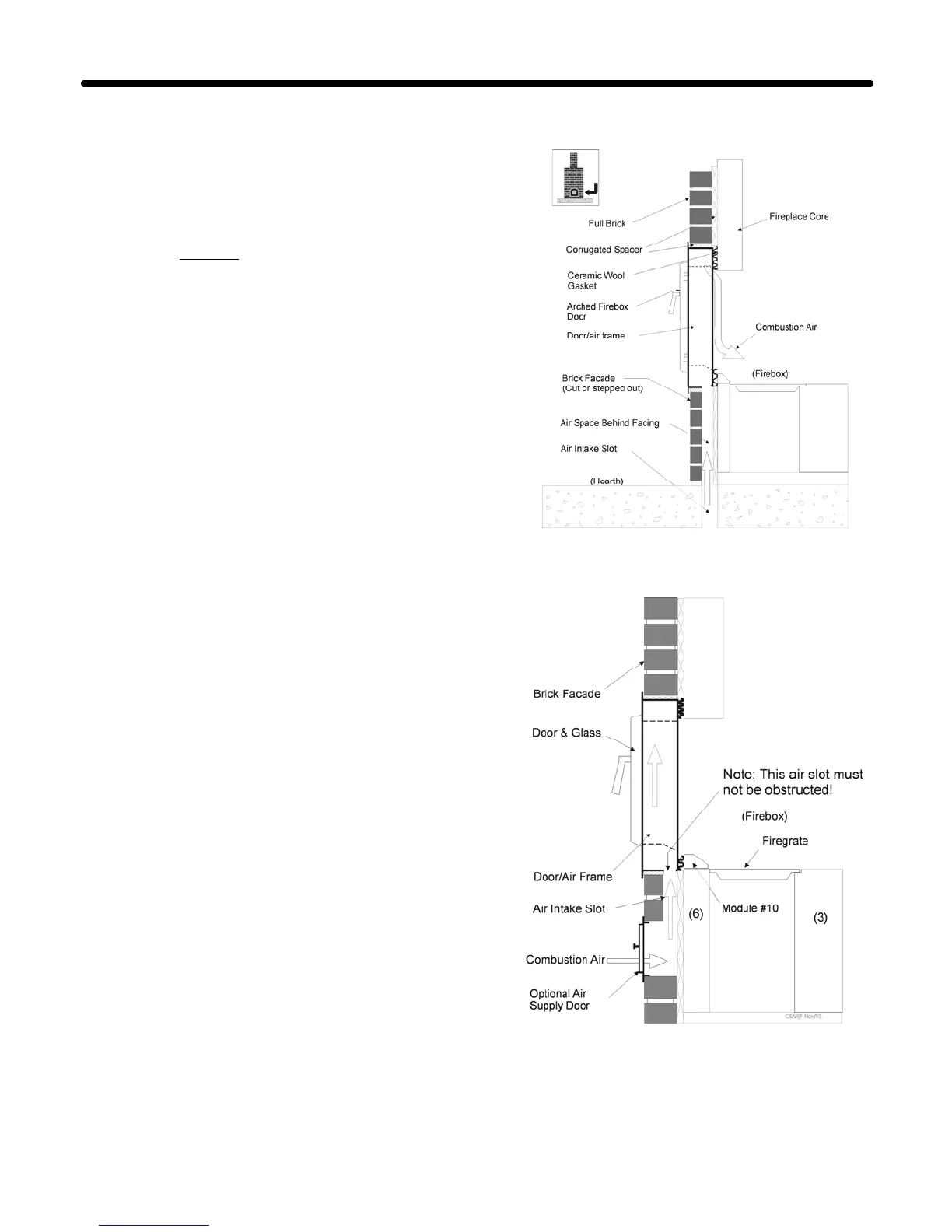

COMBUSTION AIR SUPPLY:

The Temp-Cast heater requires an unrestricted air

supply for proper combustion and maximum

performance. (This section refers to the standard

Temp-Cast “arched” door & air-frame installation.

The Temp-Cast “square” door installation is

described in a separate

manual.)

Combustion air can be drawn from outside or inside

the house and delivered by way of a 15" x 2"

(380mm x 50mm) air intake formed in front of the

heater during construction of the concrete floor pad.

Air is then directed up behind the facing masonry,

and into the hollow door frame through slots on the

bottom. The air travels up inside the door frame and

feeds the fire from above, creating an "air-wash"

across the doors to keep the glass clean. (See Fig. 1a)

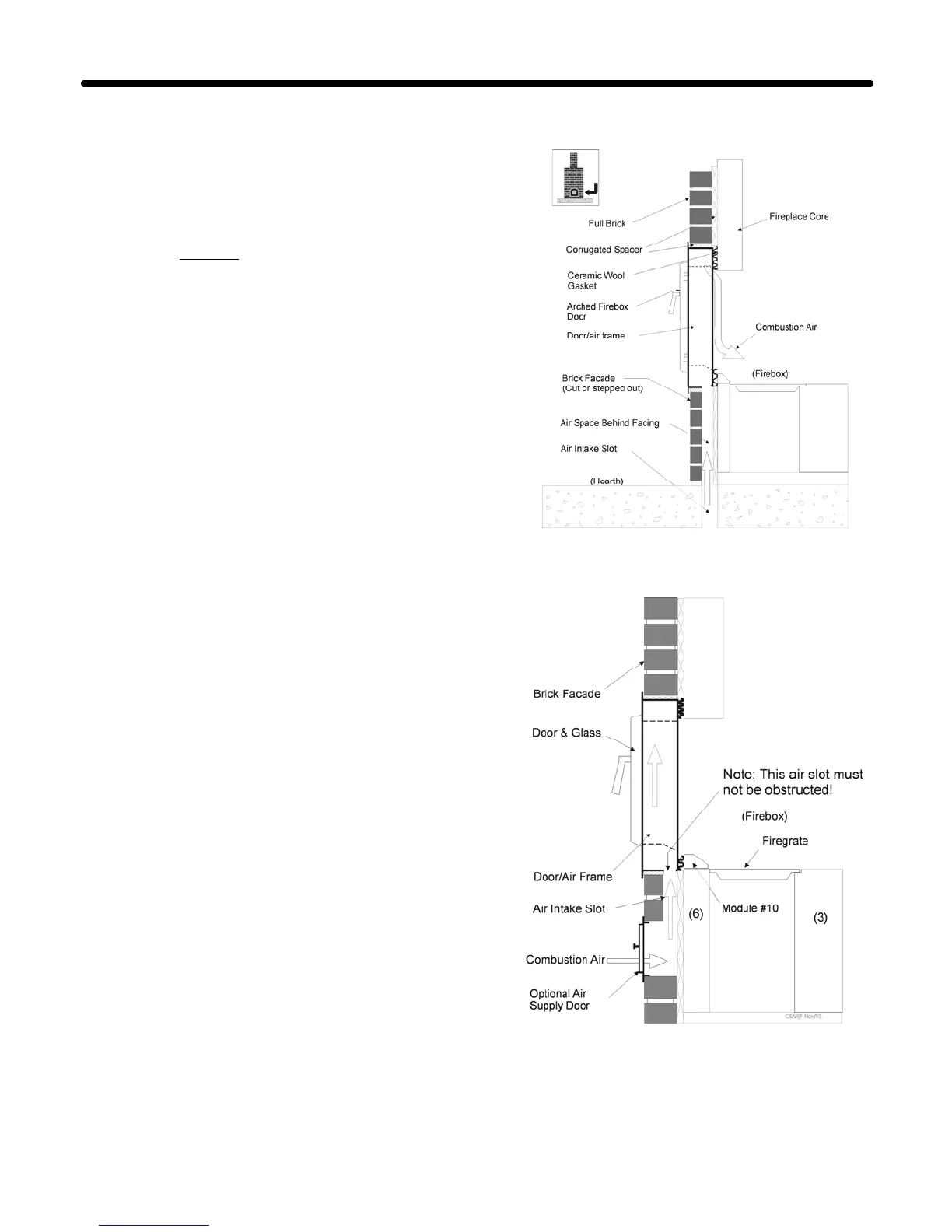

If the installation is designed to use inside air from

the same room as the heater, (such as in a basement

installation ), then an optional "air supply door" must

be purchased and installed under the loading doors.

This will allow combustion air to be drawn from the

room, travel up behind the facade and into the hollow

door frame. (Refer to Fig. 1b).

In a basement installation, outside air can still be

brought into the fireplace, if ceiling height permits.

In this case, a raised hearth can be constructed, and

6" (150mm) of fresh air can be fed into this

structure.

(A "false" chimney can be used for this fresh air

supply.) The air is brought to the front of the heater

into a 15" x 2" (380mm x 50mm) masonry slot or

custom-fabricated "boot" and treated as a normal

outside air installation.

In a "See-Through" fireplace, 8” of combustion air

must be supplied and divided equally to both door

frames to provide an "air wash" for each door glass.

(See Fig. 16)

Fig 1a

Fig 1b

Loading...

Loading...