©Copyright Task Force Tips LLC 2004-2020 27 LIX-300 October 23, 2020 Rev22

8.2 LUBRICATION

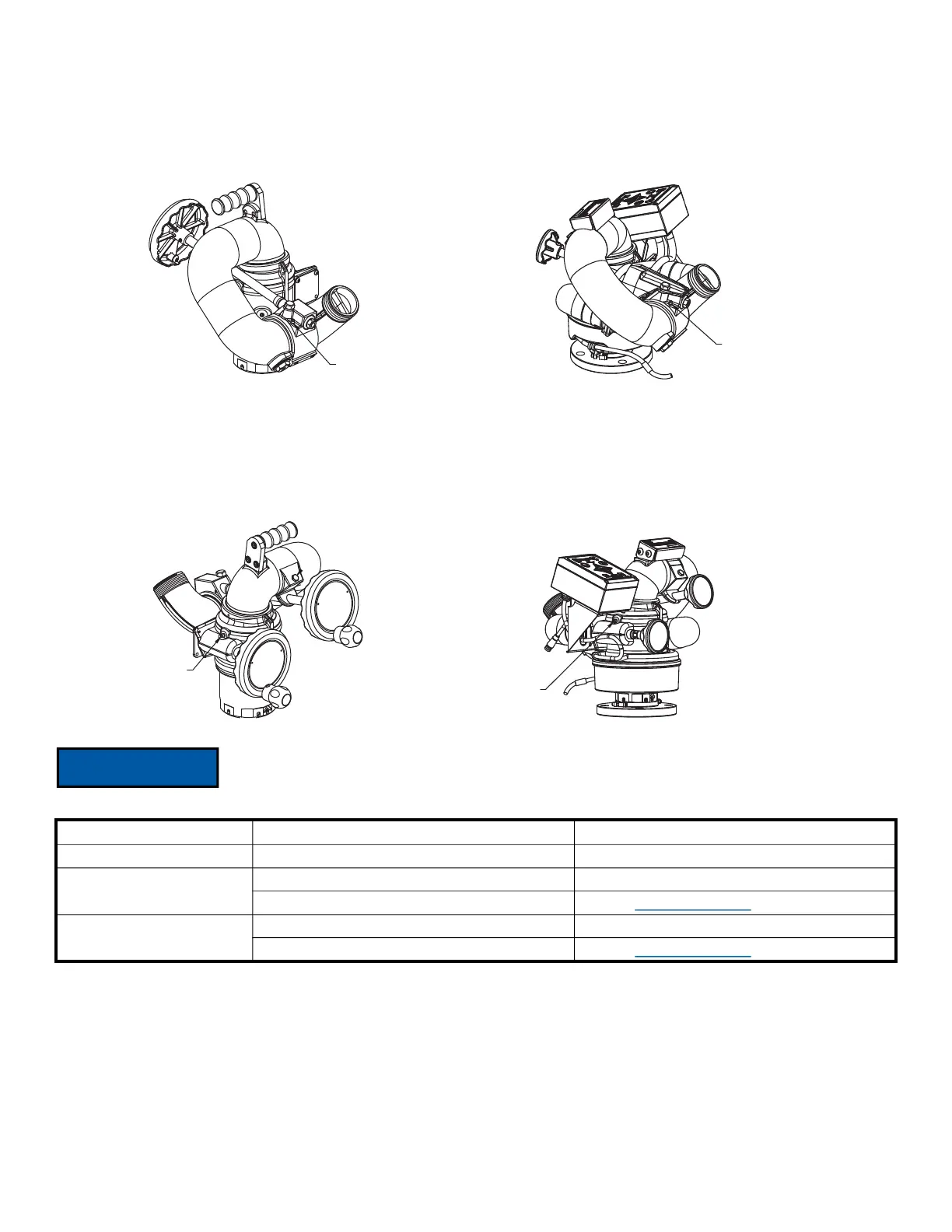

8.2.1 ELEVATION CONTROL WORM GEAR

In the event that the elevation control operation becomes stiff, grease may be applied to the elevation worm gear grease port. Turn the

hand wheel to raise the nozzle to its highest position and pump medium viscosity automotive chassis grease into the grease fitting.

Apply only enough grease to restore normal operation. If greasing does not restore normal operation, inspect for other causes of stiff

operation.

Figure 8.2.1

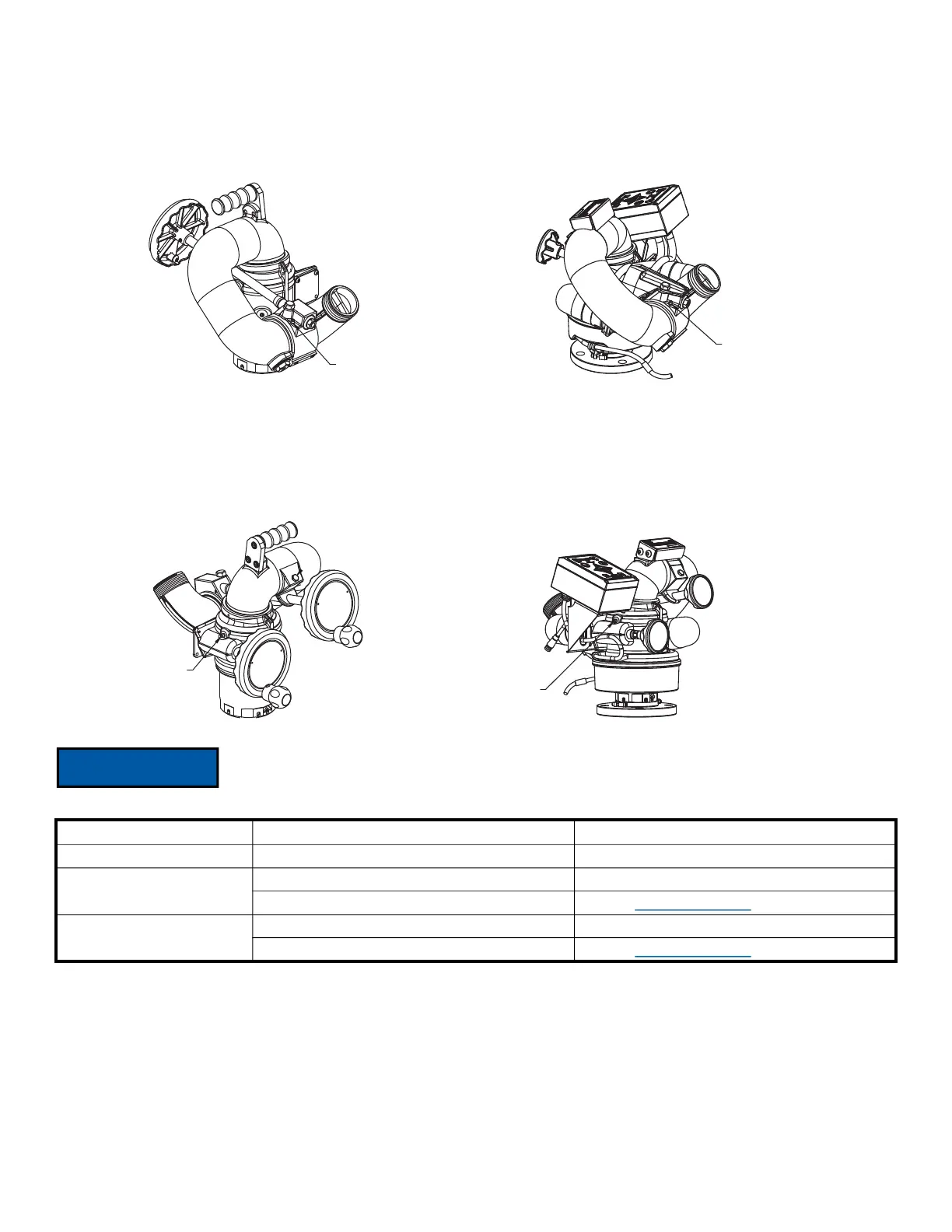

8.2.2 HORIZONTAL ROTATION WORM GEAR

The Hurricane RC and Hurricane monitor generally should not require greasing in the Horizontal (left-right) worm gear. In the event that

the operation becomes stiff, grease may be applied to the horizontal worm gear grease port. Use medium viscosity automotive chassis

grease. Apply only enough grease to restore normal operation. If greasing does not restore normal operation, inspect for other causes of

stiff operation.

Figure 8.2.2

8.3 TROUBLESHOOTING

Do not over pump grease. The monitor’s greased areas lead to large chambers that could trap

several pounds of grease before becoming visible.

SYMPTOM POSSIBLE CAUSE REMEDY

Leaks Debris or damage in the seal area Clean out debris or replace damaged parts

Elevation Binding Debris or damage to the elevation drive parts Clean out debris or replace damaged parts

Lack of lubricant Grease, (see section 8.2.1)

Horizontal Rotation Binding Debris or damage to the horizontal drive parts Clean out debris or replace damaged parts

Lack of lubricant Grease, (see section 8.2.2)

Grease Zerk

Grease Zerk

HURRICANE

Loading...

Loading...