©Copyright Task Force Tips LLC 2002-2021 14 LIN-030 May 21, 2021 Rev18

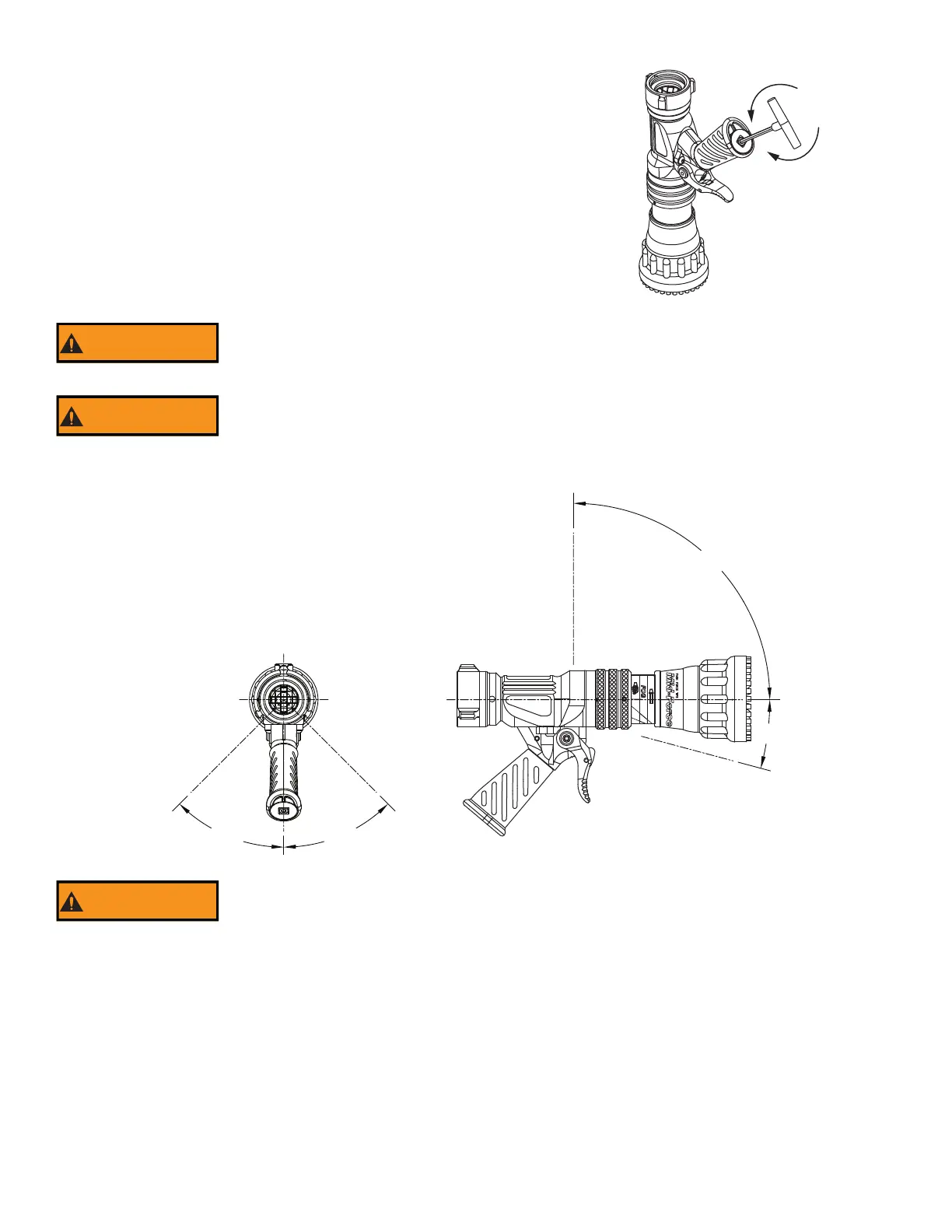

5.1.5.2 IMPULSE FLOW CONTROL SPEED ADJUSTMENT

The IMPULSE valve contains a slow close mechanism to prevent the nozzle

from slamming off if the trigger is suddenly released. The closing speed is set

at the factory to be slow enough to reduce water hammer, (“water hammer” is

always present in any valve when it is shut off. The slow close mechanism will

reduce this but cannot eliminate it completely) but fast enough to reduce the

potential danger of hose whipping from a dropped nozzle. The closing speed

may be adjusted as shown.

Do not unscrew the adjuster past the end of the hand grip (to unscrew it too far

could result in the loss of dampening fluid.)

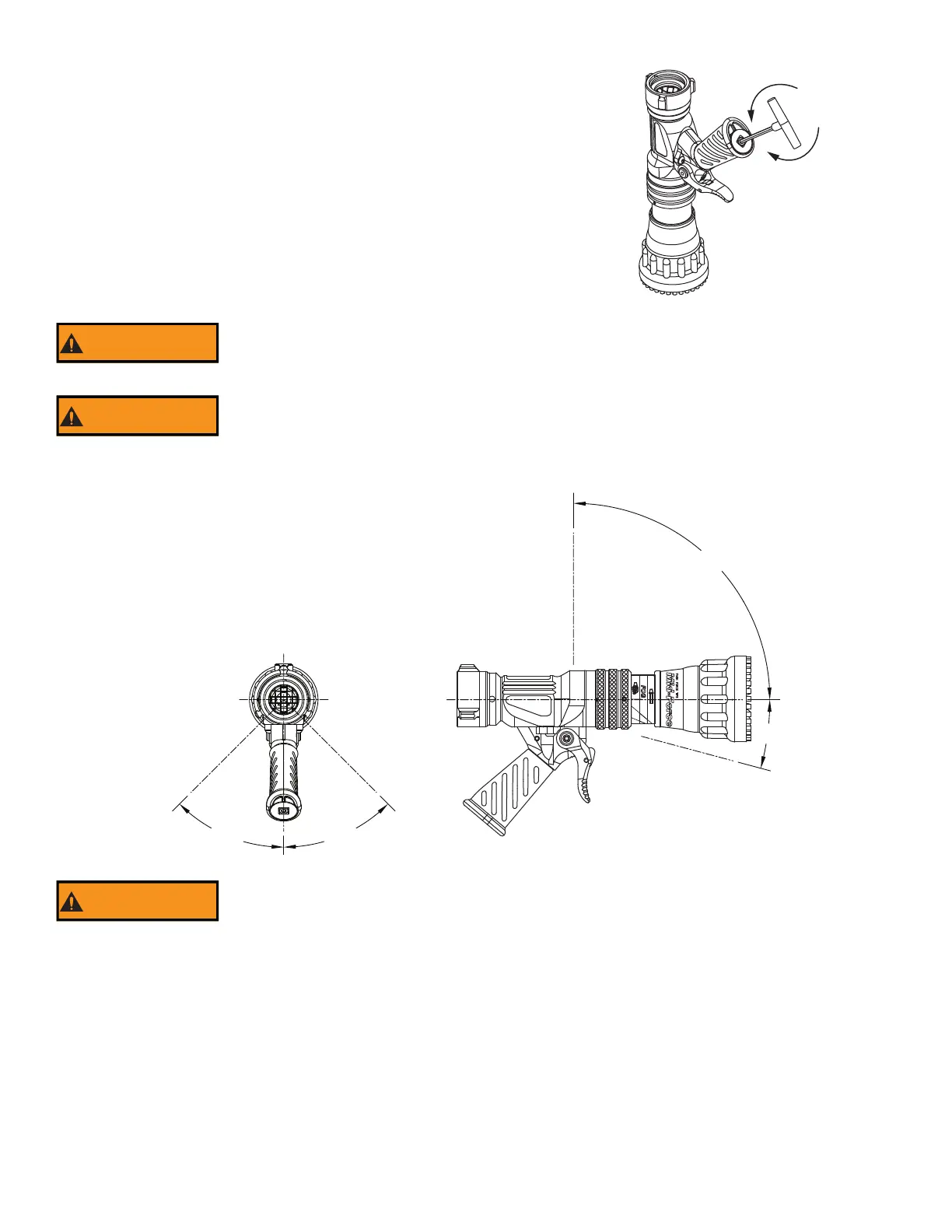

5.1.5.3 NORMAL OPERATING POSITION

Figure 5.1.5.3

A closing time that is too slow increases the risk of an out of control nozzle. Loss of control could

result in injury or death. Use caution when adjusting the closing speed, always verify performance

after adjustment, and ensure that all adjustments are made by qualified personnel under the

direction of the AHJ.

A closing time that is too quick increases the risk of water hammer from a suddenly released trigger

valve. Loss of control or a burst hose could result in injury or death. Use caution when adjusting

the closing speed, always verify performance after adjustment, and ensure that all adjustments are

made by qualified personnel under the direction of the AHJ.

Quickly releasing the trigger outside normal operating orientation will likely cause faster valve shut

off, increasing risk of a burst hose. This could result in injury. Slowly release the trigger when

operating outside of the nozzle’s normal orientation.

Figure 5.1.5.2

45°

15°

90°

45°

Horizontal

Slow Closer

Operating Range

Slow Closer

Operating Range

Loading...

Loading...