©Copyright Task Force Tips LLC 2002-2021 12 LIN-030 May 21, 2021 Rev18

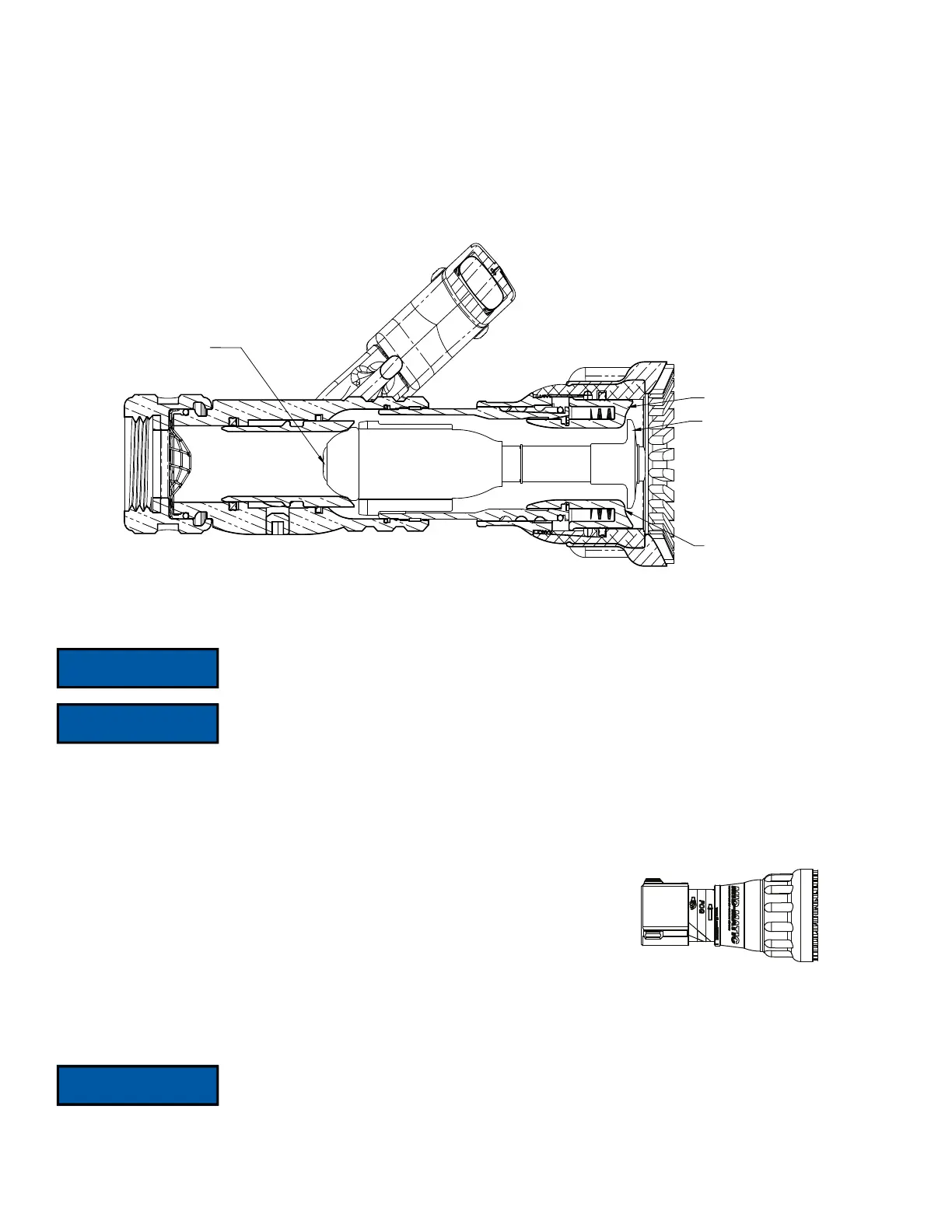

4.5 ULTIMATIC INITIAL OPENING ADJUSTMENT OPTION

Initial opening is the small gap between the back of the baffle and the front of the nozzle’s discharge opening (barrel cone). This small

gap provides a small amount of flow until line pressure/flow begins moving the automatic control unit and the baffle forward allowing the

rated flow range of the nozzle.

If no initial opening is desired the initial opening can be adjusted back to zero. Looking inside the inlet end of the nozzle there is a small

plastic screw. A long 7/32” hex wrench can be insert into the inlet end of the nozzle through the center of the debris screen then down

into the hex of the plastic screw. Turn the screw ¼ turn counterclockwise (unthreading it slightly from the valve plug) to set the initial

opening to approximately a zero gap size.

Once this adjustment is made, the nozzle will flow little to no water at low pump pressures when the valve handle is in the open position.

Figure 4.5

5.0 NOZZLE CONTROLS

5.1 FLOW CONTROL

5.1.1 LEVER TYPE FLOW CONTROL (SLIDE VALVE)

On models that use a lever type valve handle, the nozzle is shut off when the handle is fully forward. Slide valve models have detented

flow positions. These detent positions allow the nozzle operator to regulate the flow of the nozzle depending on the need or what can be

safely and effectively handled. TFT recommends the use of a pistol grip for easier handling. For additional stress reduction, a hose rope

or strap may also be used. This permits more effective use and ease of advancement, while minimizing strain and fatigue.

5.1.2 TIP ONLY

Tip Only nozzles have NO shut-off valve within the nozzle and MUST be used

with a separate ball valve attached to the nozzle.

5.1.3 LEVER TYPE FLOW CONTROL (BALL VALVE)

Models with a ball valve are shut off when the valve handle is fully forward.

Pulling back on the handle opens the valve. The ball valve allows the nozzle

operator to regulate the flow of the nozzle depending on the need or what can be safely and effectively handled. TFT recommends the

use of a pistol grip for easier handling. For additional stress reduction, a hose rope or strap may also be used. This permits more

effective use and ease of advancement, while minimizing strain and fatigue.

Control valves must be opened slowly to eliminate unnecessary strain on the hose and couplings,

and reduce pressure surges.

Nozzles attached to an in-service hose shall be stored in the off position.

In partially open positions, a ball valve will cause turbulence and adversely affect stream quality.

ADJUST INITIAL OPENING

SCREW HERE

BARREL CONE

BAFFLE

INITIAL OPENING GAP

VALPARAISO IN 46383-6040 +1.219.462.6161 800.348.2686

Figure 5.1.2

Loading...

Loading...