©Copyright Task Force Tips LLC 2002-2021 6 LIN-030 May 21, 2021 Rev18

3.2 SPECIFICATIONS

Table 3.2

3.3 NOZZLE COUPLINGS

NH (National Hose) threads are standard on all nozzles. Other threads such as NPSH (National Pipe Straight Hose) may be specified at

time of order.

3.4 USE WITH SALT WATER

Use with salt water is permissible provided the equipment is thoroughly cleaned with fresh water after each use. The service life of the

equipment may be shortened due to the effects of corrosion, and is not covered under warranty.

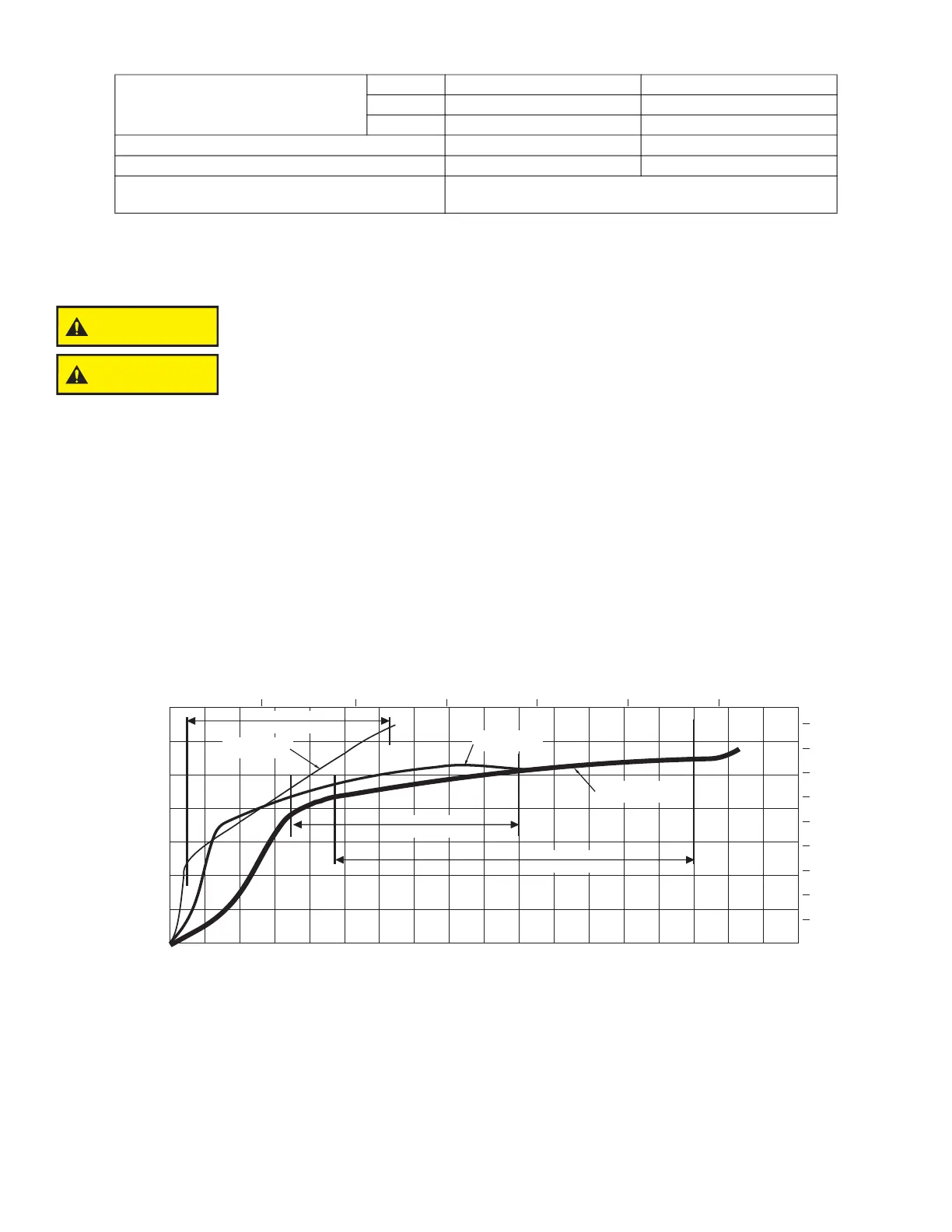

4.0 FLOW CHARACTERISTICS

The following graphs show the typical performance of Ultimatic, Mid-Matic, and Handline nozzles.

SPECIAL CONFIGURATIONS If nozzles are made according to the special marking or performance requirements of the fire

department, the characteristics may differ from the published data in this manual. Repair parts specific to each serial number may differ

from those shown in the service procedure. The required parts for each serial number are available online by entering tft.com/H123456

with the numbers corresponding to the serial number engraved on the product.

Figure 4.0A

Maximum operating pressure

(with valve shut off)

Ultimatic 800 psi 55 bar

Mid-Matic 300 psi 21 bar

Handline 300 psi 21 bar

Operating temperature range of fluid 33 to 120° F 1 to 50° C

Storage temperature range 40 to 150° F -40 to 65° C

Materials used Aluminum 6000 series hard anodized MIL8625 class 3 type

2, stainless steel 300 series, nylon 6-6, nitrile rubber

CAUTION

Mismatched or damaged waterway connections may cause equipment to leak or uncouple under

pressure. Failure could result in injury. Equipment must be mated to matched connections.

CAUTION

Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability to

uncouple the connection, or complete loss of engagement over time. Failure could cause injury. Per

NFPA 1962, if dissimilar metals are left coupled together, an anti-corrosive lubricant should be

applied to the connection and the coupling should be disconnected and inspected at least

quarterly.

FLOW (GPM)

NOZZLE PRESSURE (PSI)

0

20

40

60

80

100

120

140

02040 24060 80 100 120 140 160 180 200 220

260 280 300 320 340 360

MID-MATIC

ULTIMATIC

HANDLINE

MID-MATIC

FLOW RANGE

HANDLINE

FLOW RANGE

ULTIMATIC

FLOW RANGE

200 400 600 800 1000 1200

FLOW (GPM)

FLOW (L/min)

2

4

6

8

NOZZLE PRESSURE (BAR)

100 psi (7 bar) Ultimatic, Mid-Matic, and Handline

Loading...

Loading...