©Copyright Task Force Tips LLC 2002-2021 18 LIN-030 May 21, 2021 Rev18

9.2 FIELD LUBRICATION (SLIDE VALVE AND PATTERN CONTROLS)

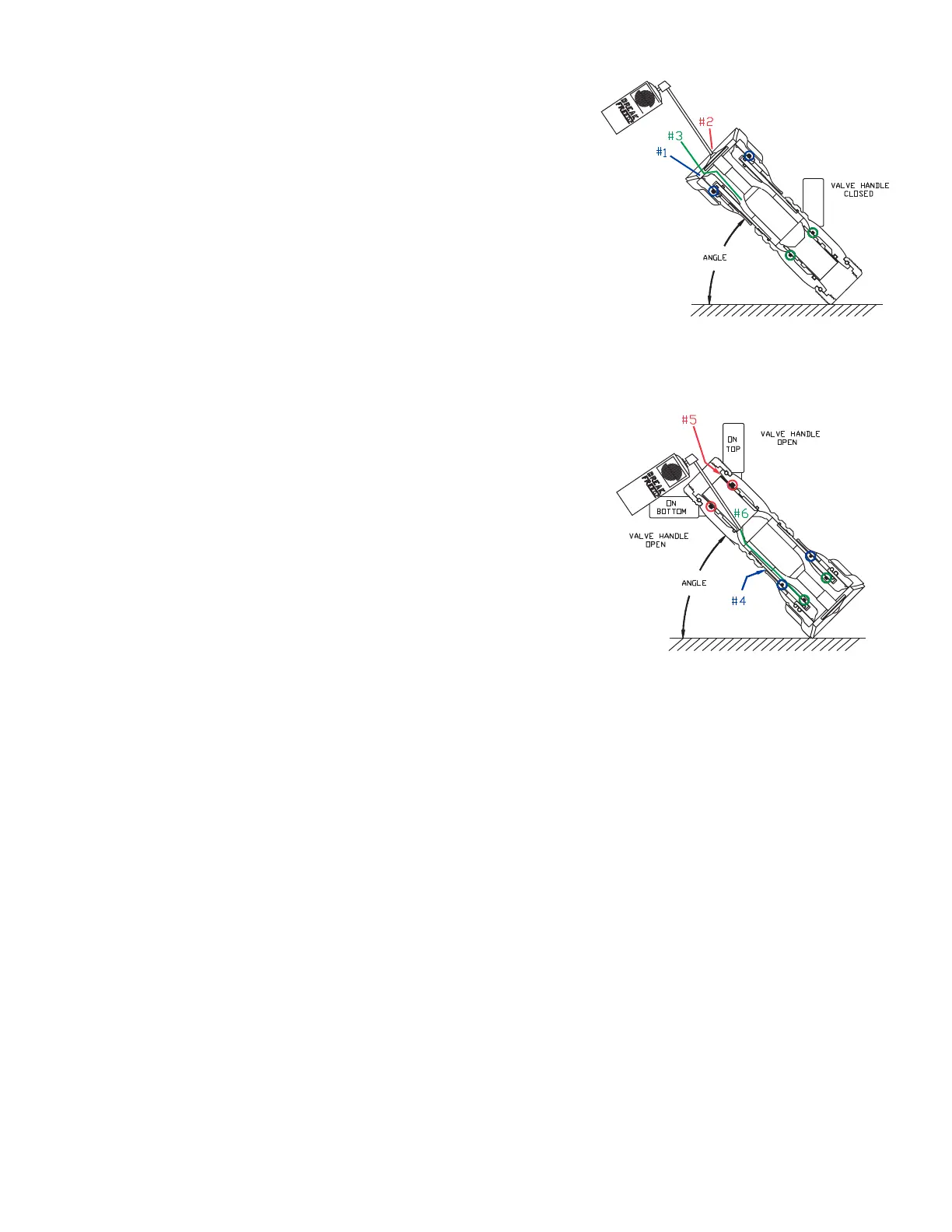

PART 1 - COUPLING DOWN

Position the nozzle at a 45 degree angle with the COUPLING END DOWN. CLOSE

the valve handle and set the pattern to STRAIGHT STREAM. Then, spray a short

burst into these areas:

#1 FRONT PATTERN CONTROL SEAL

Spray between the pattern control and the barrel.

#2 PRESSURE CONTROL UNIT

7. Place check sticks behind the baffle while the shaper is in flush.

8. Work lubrication into the O-rings by cycling the baffle in and out several times

using the check sticks.

#3 FRONT SLIDER SEAL

1. Rotate the shaper into FLUSH position.

2. Spray down the front end of the nozzle to dribble lubricant into the clearances

between the shaper and the valve body.

While holding the nozzle at an angle, wait 30 seconds for the lubricant to penetrate into the clearances. Cycle the valve handle and

rotate the shaper from straight stream to full flush several times, and then proceed to the next section.

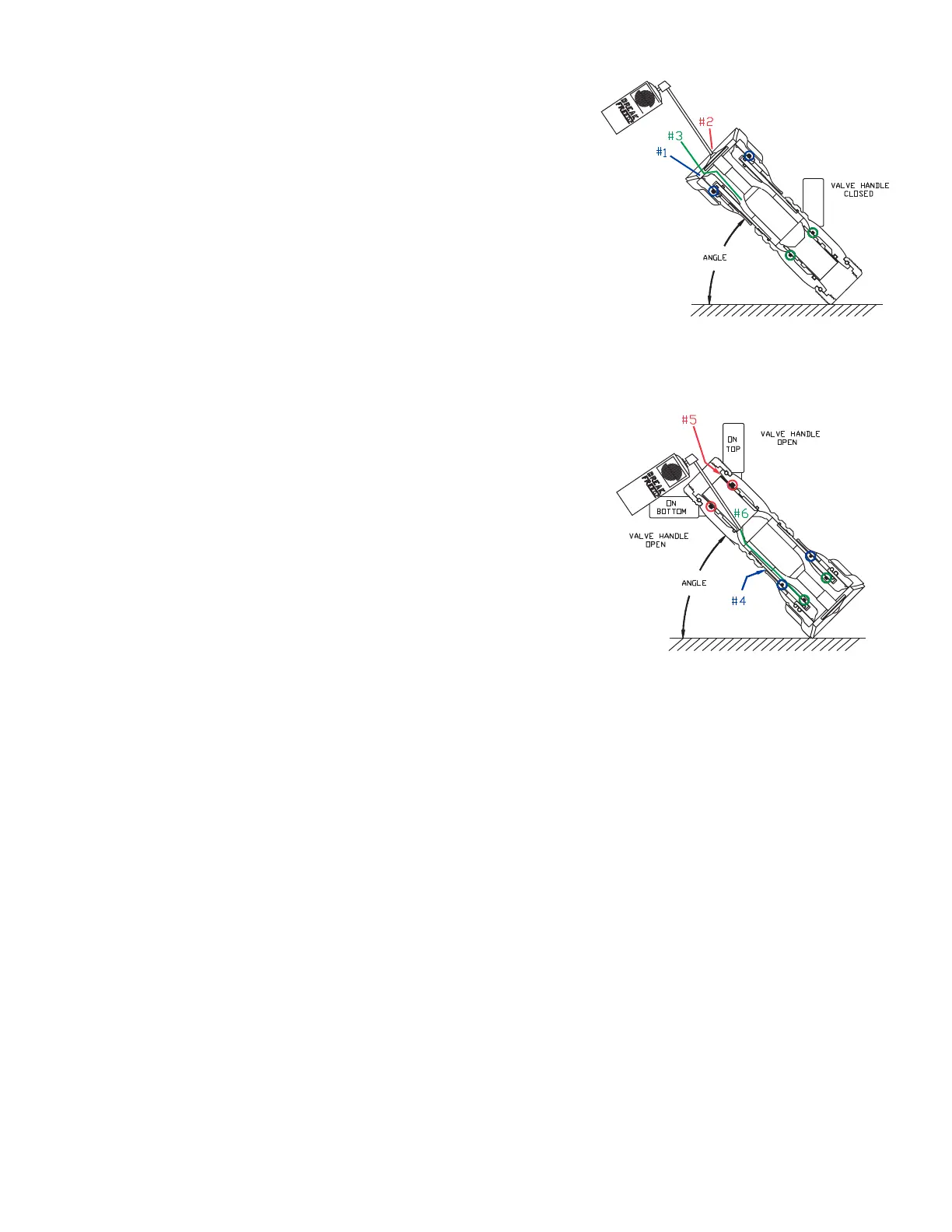

PART 2 - COUPLING UP

Position the nozzle at a 45 degree angle with the BUMPER END DOWN. OPEN the

valve handle and set the pattern to FLUSH. Then, spray a short burst into these

areas:

#4 REAR SHAPER SEAL

Spray down the clearance between the label and the shaper guide.

#5 REAR SLIDER SEAL

Spray down the clearance between the slider and the valve body.

#6 FLUSH MECHANISM SEAL

1. With the handle on top, spray down into the nozzle. The aerosol extension tip

will help direct the spray into clearances leading to the O-ring.

2. Rotate the nozzle so the valve is on the bottom and spray another short burst.

#7 HANDLE DETENTS

Spray a small amount on the detent followers on each side of the handle.

While holding the nozzle at an angle, wait 30 seconds for the lubricant to penetrate into the clearances. Cycle the valve handle several

times. Rotate the pattern control from straight stream to full flush several times. The pattern control should move freely and easily. The

barrel cone should move forward to within 1/16” of the baffle before the shaper reaches straight stream position. Wipe off excess

lubricant.

IF THIS PROCEDURE DOES NOT RESTORE SMOOTH OPERATION OF THE IMPULSE TRIGGER SYSTEM,

THEN FACTORY SERVICE IS NEEDED. • 24-HOUR HOT LINE — 800-348-2686 • tft.com

Figure 9.2A

Figure 9.2B

Loading...

Loading...