EX-TRAFIRE

®

55SD

Operator Manual, Revision T-34-36

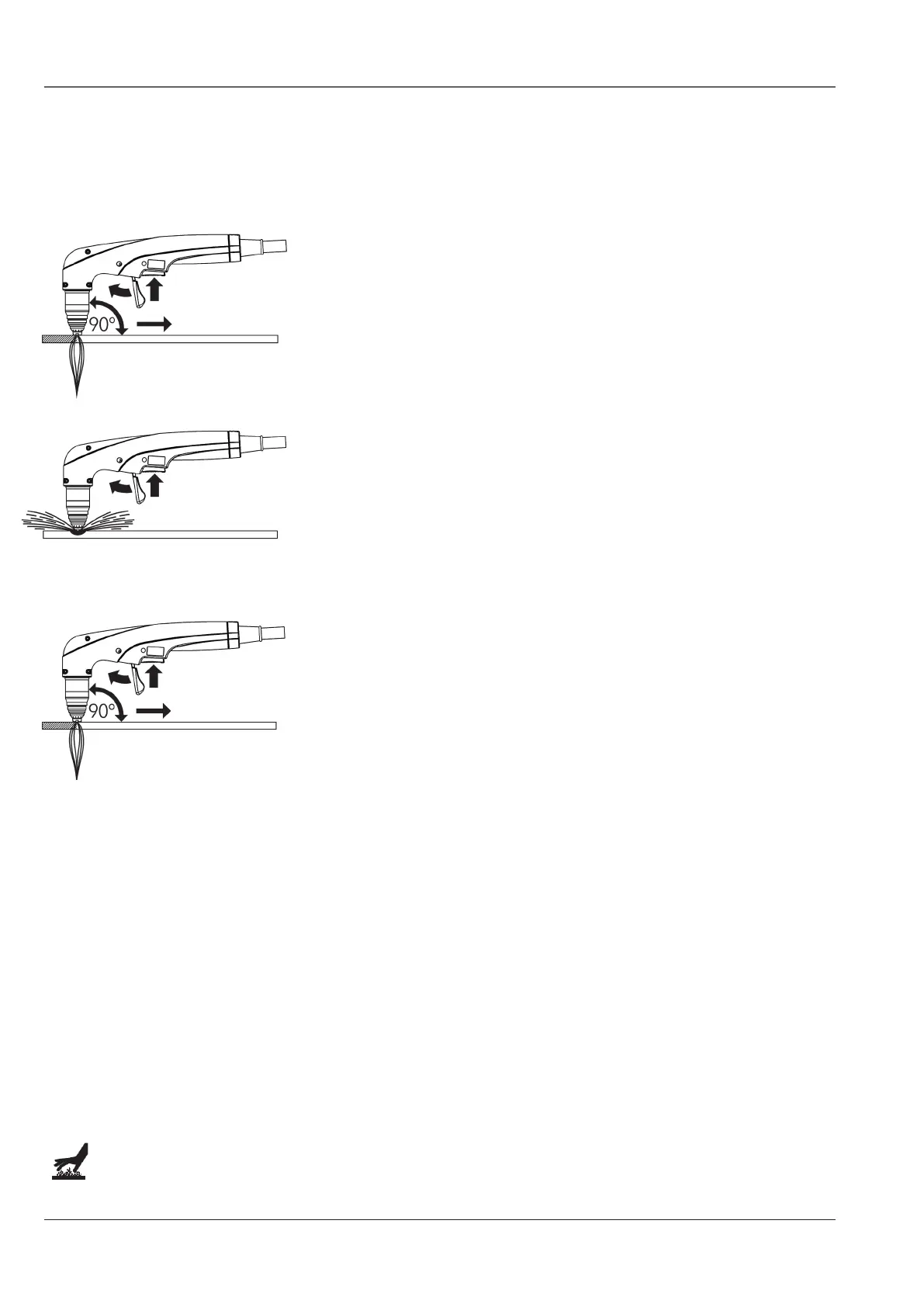

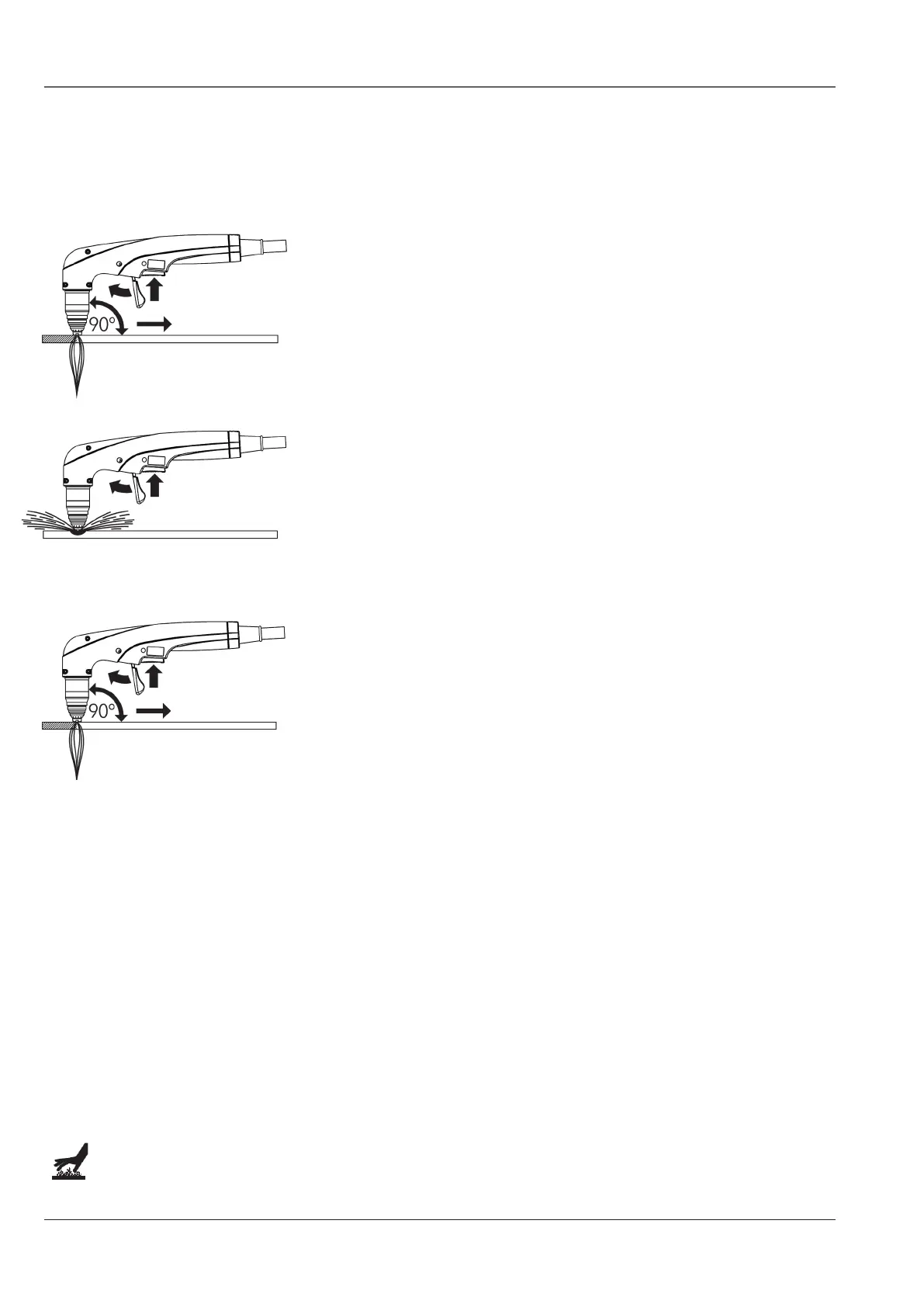

Hand torch cutting technique

Avoid unnecessary firing of the torch, each firing of the torch reduces the lifetime of the electrode

and nozzle�

When cutting, ensure the arc spray exits the underside of the work

piece�

Incomplete severance is indicated by an upward arc spray� This can

be caused by the following:

• Excessive travel speed

• Incorrect power settings

• Incorrect gas pressure settings

• Worn/damaged consumables

• or by any combination of the above

Hold the torch vertically and watch the arc while cutting along the

line�

Shielded consumables� Make light contact between the shield and the work piece, pull the torch at

a steady travel speed�

• Pulling the torch gives better control compared to pushing�

• For cutting thin material, reduce the amperage to the optimum to achieve the highest cut

quality�

• For straight line/bevel cutting, use a straight edge as a guide� To cut circles, use a template or

a circle cutting attachment�

• Gas Post flow – After the torch trigger is released, the gas will continue to flow up to 55

seconds (according to adjusted cutting current) to cool the torch and consumables�

Note: The torch will be ready to restart by depressing the torch trigger during the post flow period�

To stop the post flow, depress the torch trigger quickly and release�

DANGER! Consumables can remain hot after the post-flow period�

Direction of cut

Direction of cut

Loading...

Loading...