Manual 0-2859 3-3 INSTALLATION PROCEDURES

B. 208/230-Volt Power Supply

This power supply includes a factory-installed input

power cable and plug.

1. Check your power source for correct voltage before

plugging in the unit.

2. Connect the input power cable (or close the main dis-

connect switch) to supply power to the system.

CAUTION

The primary power source and power cable must

conform to local electrical code and the recom-

mended circuit protection and wiring requirements

(refer to table in Appendix 1).

3.06 Gas Connections

A. Gas Requirements

WARNING

This unit is not to be used with oxygen (O

2

).

Gases: Single Gas - Plasma/Secondary

Compressed Air Only

Pressure: 70 psi (4.8 bar)

CAUTION

Maximum pressure at inlet must not exceed 125 psi

(8.6 bar)

Flow: Cutting - 400 scfh (190 lpm)

Gouging - 400 scfh (190 lpm)

scfh = standard cubic feet per hour.

B. Checking Air Quality

To test the quality of air, place the RUN/SET switch to

SET position, place a welding filter lens in front of the

torch and turn on the gas. Any oil or moisture in the air

will be visible on the lens. Do not initiate an arc!

CAUTION

Air supply must be free of oil, moisture, and other

contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even com-

plete torch failure. Contaminants may cause poor

cutting performance and rapid electrode wear.

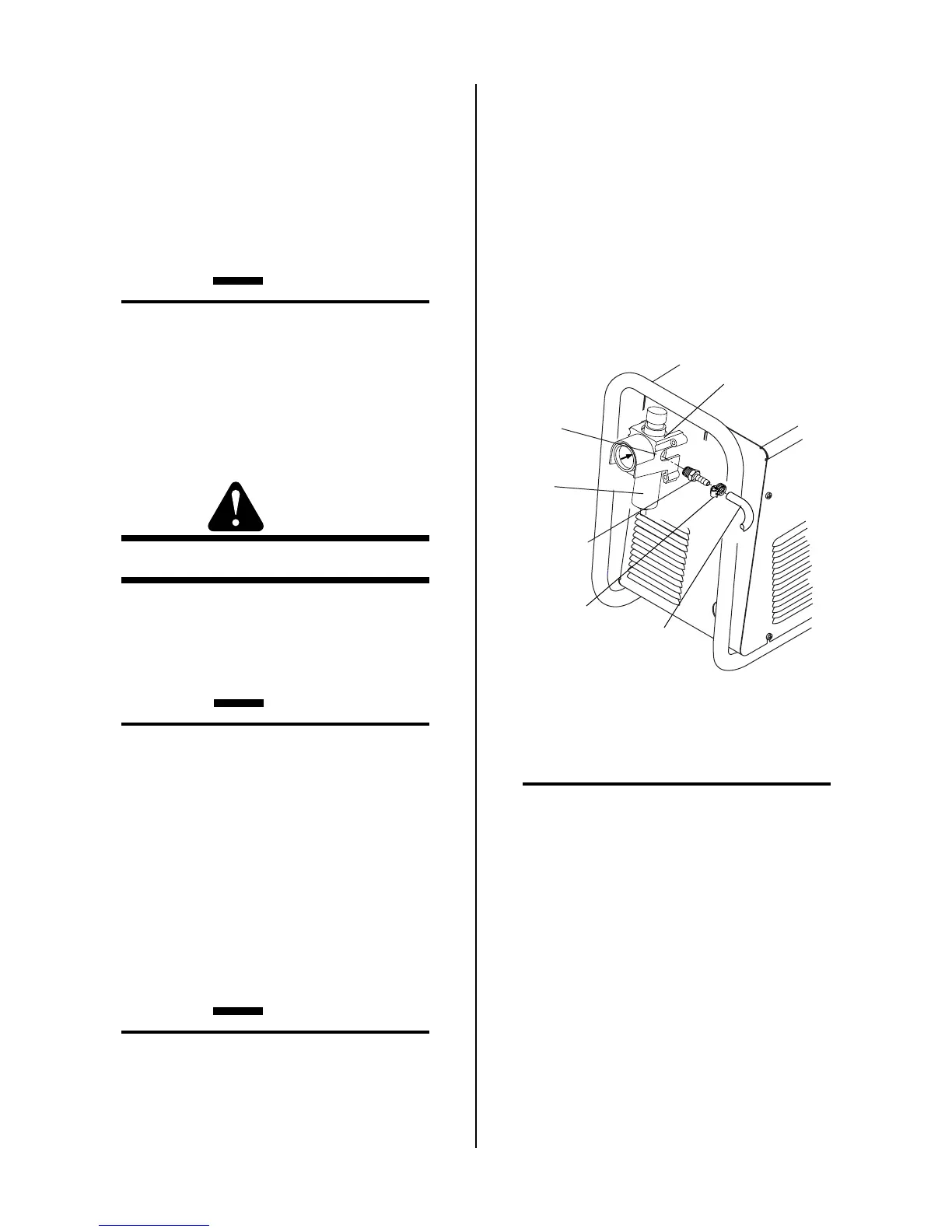

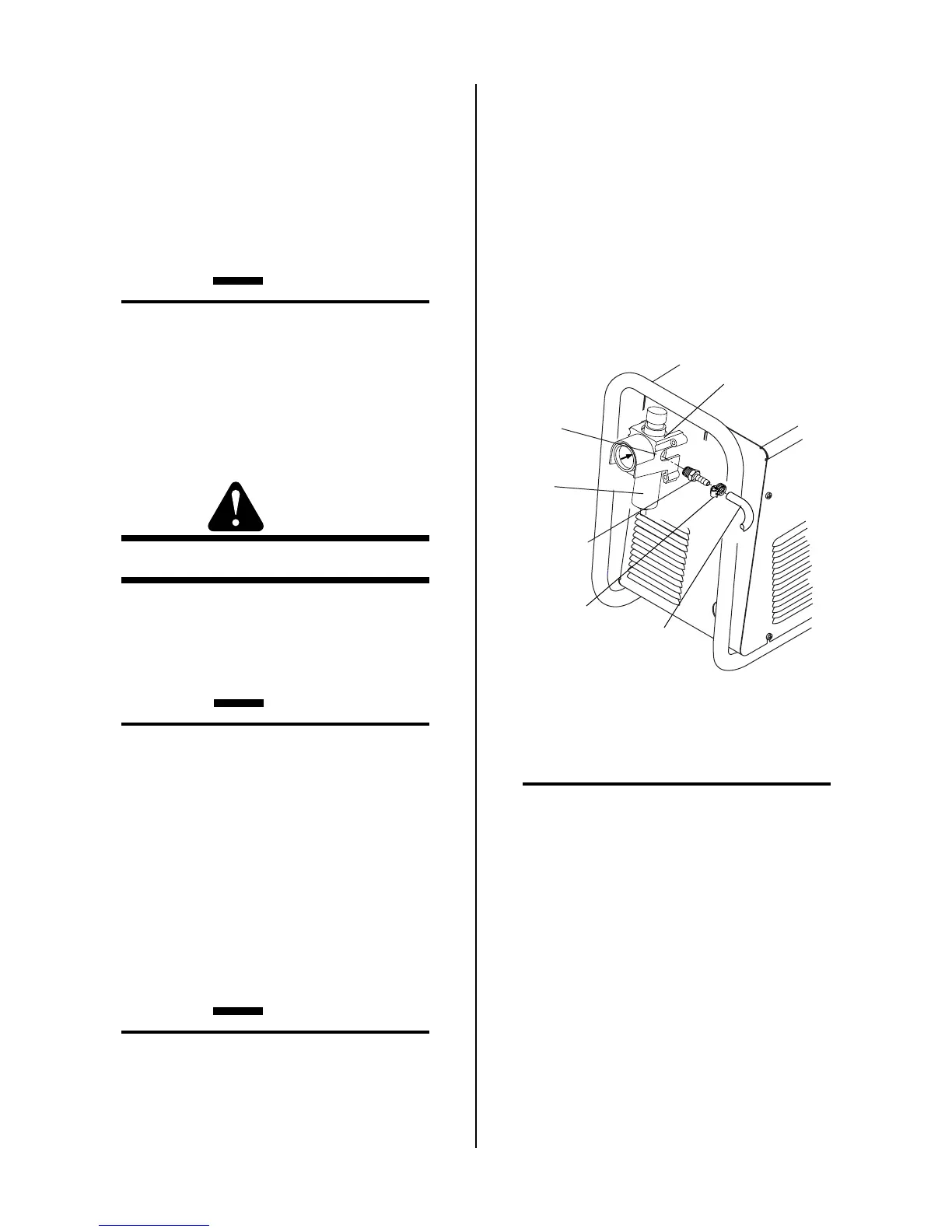

C. Connecting Gas to Power Supply

The gas supply is connected to the Regulator/Filter As-

sembly located on the rear of the unit. The connection is

the same for compressed air or high pressure gas cylin-

ders. If an optional air line filter is to be installed, refer to

procedures in subsection 3.06-D.

Connect the gas supply as follows:

1. Use customer-supplied fittings to connect the gas line

to the Regulator/Filter. Typical fittings are shown;

other fittings may be used.

Art # A-02999

Hose Clamp

1/4 NPT to 1/4"

(6mm) Fitting

Regulator/Filter

Assembly

Inlet Port

Gas Supply

Hose

Bowl

Gas Connection to Regulator/Filter Assembly

NOTE

For a secure seal, apply thread sealant to the fit-

ting threads, according to manufacturer's instruc-

tions. Do Not use Teflon tape as a thread sealer as

small particles of the tape may break off and block

the small gas passages in the torch.

D. Installing Optional Air Filter Kits

Additional filtering is recommended when using air from

a compressor to insure that moisture and debris from the

supply hose does not enter the torch. Although the Regu-

lator/Filter Assembly has its own filter, the optional fil-

ter kits are recommended for improved filtering.

1. Optional Single-Stage Air Filter Kit

This optional in-line air filter for use on compressed

air shop systems is highly effective at removing mois-

ture and particulate matter from the air stream to at

least 0.85 microns.

Loading...

Loading...