Manual 0-2859 5-5 CUSTOMER/OPERATOR SERVICE

2. Gas supply pressure too high

a. Maximum 125 psi (8.6 bar) inlet pressure

3. Shield Cup not properly installed.

a. Check to see that Control Circuit (PIP) pins are

installed. Refer to the torch manual for details.

4. Faulty components in unit

a. Return for repair or have qualified technician

repair per Service Manual.

J. Torch cuts but not adequately

1. Current set too low

a. Increase current setting.

2. Torch is being moved too fast across workpiece

a. Reduce cutting speed (refer to Torch Instruction

Manual supplied with torch).

3. Excessive oil or moisture in torch

a. Hold torch 1/8 inch (3 mm) from clean surface

while purging and observe oil or moisture

buildup (do not activate torch).

4. Torch tip being dragged on work.

a. Lift torch tip off work. At output settings over

40 amps, control circuitry automatically reduces

output current to 40 amps if the torch tip con-

tacts the workpiece.

5.05 Power Supply Basic Parts

Replacement

WARNING

Disconnect primary power to the system before dis-

assembling the torch, leads, or power supply.

This section describes procedures for basic parts replace-

ment. For more detailed parts replacement procedures,

refer to the Power Supply Service Manual.

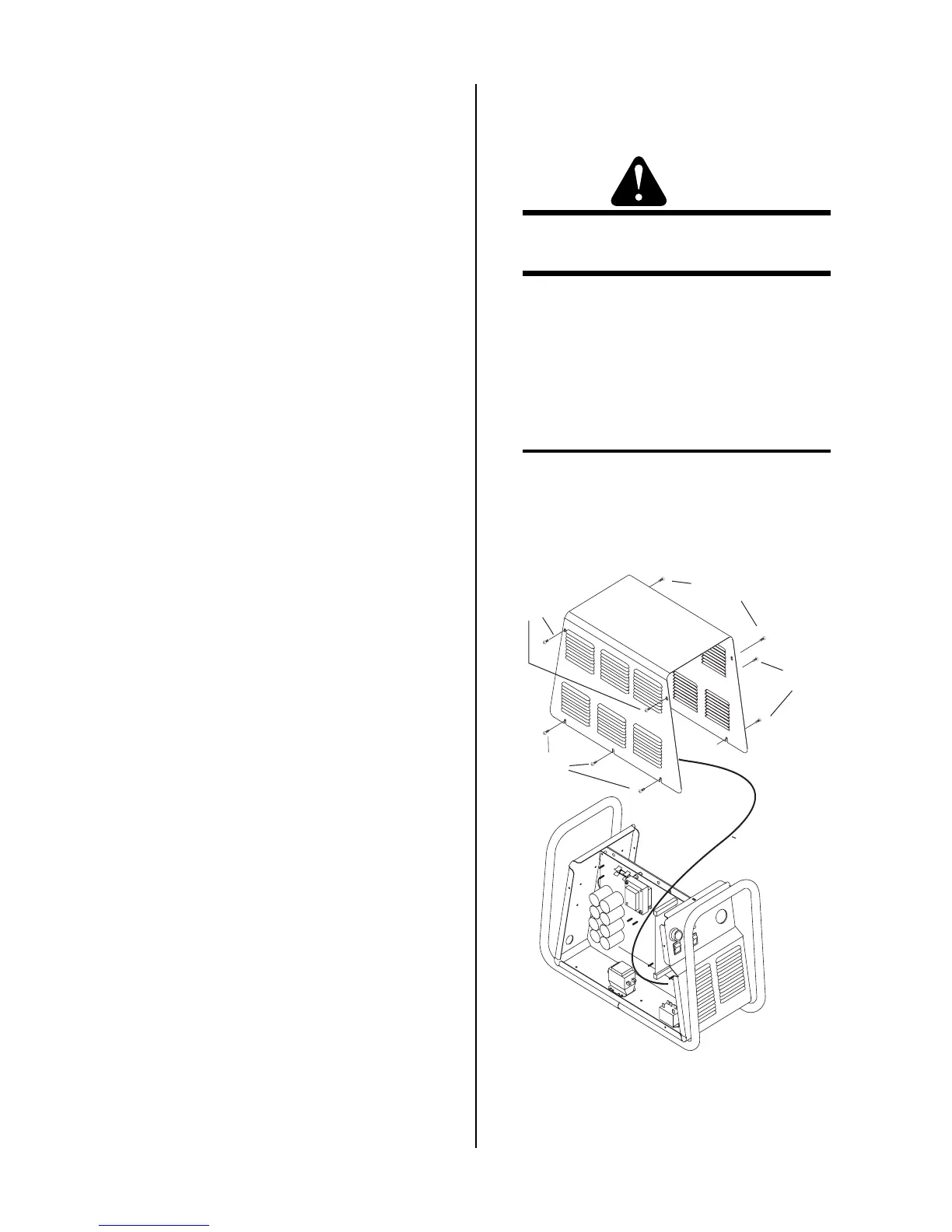

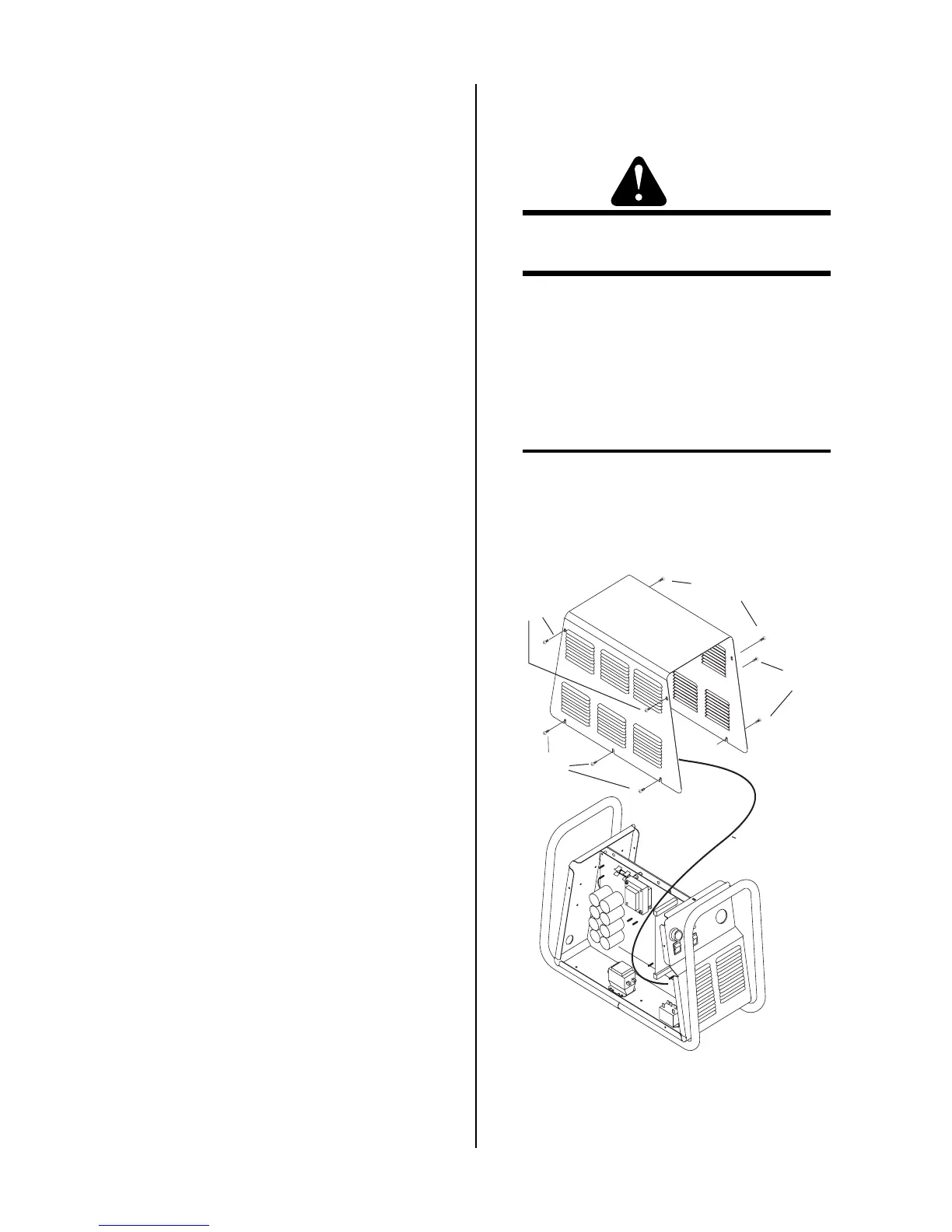

A. Cover Removal

1. Remove the upper screws which secure the cover

to the main assembly.

NOTE

There is a ground wire connection to the inside of

the unit. There is no need to disconnect the ground

wire, unless there is a need for more room to work.

A-03001

Lower

screws

Upper screws

Ground wire

Lower

screws

Upper

screws

Cover Removal

Loading...

Loading...