Do you have a question about the Thermal Dynamics SL60 and is the answer not in the manual?

Explains the categorization of notes, cautions, and warnings used to highlight important information.

Outlines critical safety measures for operating plasma arc equipment, covering gases, electric shock, fire, and noise hazards.

Lists standards and publications for further information on safety and practices.

States manufacturer information and product conformity to applicable directives and national legislation.

Details the limited warranty terms, conditions, and exclusions for Thermal Dynamics products.

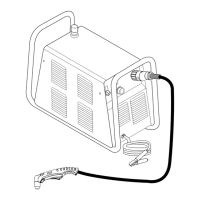

Defines the manual's coverage of SL60 and SL100 Plasma Cutting Torches and service restrictions.

Provides a general overview of plasma torch design, operation, and gas flow principles.

Lists technical specifications for torch configurations, leads, ratings, and compatible power supplies.

Lists optional accessories available to adapt the system or enhance performance.

Explains the fundamental principles of plasma gas flow, distribution, and arc formation.

Introduces the installation procedures applicable to the Torch and Leads Assemblies.

Guides on selecting an appropriate installation site with considerations for safety and space.

Provides instructions for unpacking system components and checking for shipping damage.

Details setup requirements for the hand torch, including proper part installation.

Guides on setting up the machine torch, including mounting and alignment.

Provides instructions for connecting torch leads to the power supply based on system type.

Details connecting compressed air, checking air quality, and filtering requirements.

Introduces torch assemblies and provides operating procedures.

Explains the overall function of the torch system for plasma cutting and gouging.

Outlines the procedure for starting operations at the beginning of each shift.

Guides on selecting appropriate torch parts for different cutting and gouging operations.

Discusses factors affecting cut quality and characteristics like surface finish and bevel angle.

Provides general safety and handling information for cutting processes.

Details operating procedures for hand torch use, including standoff, drag, and piercing cuts.

Explains operating procedures for machine torches, focusing on cutting and travel speed.

Lists factors impacting cutting speed and system performance.

Covers gouging parameters, travel speed, current settings, lead angle, and standoff distance.

Introduces basic maintenance procedures performable by operating personnel.

Details general maintenance tasks including torch cleaning and O-ring lubrication.

Lists common cutting faults and their possible causes for troubleshooting.

Guides on inspecting and replacing consumable torch parts like tips, electrodes, and shield cups.

Provides a guide to troubleshoot common torch problems and their remedies.

Introduces the parts list breakdown and explains its arrangement.

Guides on how to order replacement parts by catalog number and product details.

Lists replacement parts for hand torches with corresponding catalog numbers.

Lists replacement parts for machine torches with unshielded leads.

Lists replacement leads assemblies for shielded machine torches.

Illustrates and describes consumable parts for various hand torch applications.

Lists the contents of hand torch spare parts kits for different amperage ratings.

Illustrates consumable parts for SL100 machine torches.

Lists the contents of machine torch spare parts kits.

Illustrates consumable parts for automated torches.

Lists the contents of automated torch spare parts kits.

Lists part numbers for complete torch and leads assembly replacements.

Lists various optional accessories available for the system.

Compares hand cutting speeds with machine cutting and their effects on quality.

Provides contact details for Thermal Dynamics in the USA.

Lists contact information for Thermal Dynamics in Brazil.

Provides contact details for Thermal Dynamics in Canada.

Lists contact information for Thermal Dynamics in Chile.

Provides contact details for Thermal Dynamics in Europe.

Lists contact information for Thermal Dynamics in China.

Provides contact details for Thermal Dynamics Asia.

Lists contact information for Cigweld in Australia.

Provides contact details for Thermal Dynamics in Italy.

Lists contact information for Thermal Dynamics in South Africa.

Provides contact details for Thermal Dynamics International.

| Brand | Thermal Dynamics |

|---|---|

| Model | SL60 |

| Category | Welding System |

| Language | English |