Gas supply connection

The gas connection are located on the back of the unit.

The gas must be supplied to each unit via a pressure reducer with the inlet pressure set

to between 0.8 and max. 1 bar.

This setting must not be changed for safety reasons

(FRG: ZH 1/119).

The gases must have at least 99.5% purity.

If several units are placed in the same room, special ventilation measures are required.

CO

2

gassing

Connect the gas cylinder to the gas nozzle on the unit.

O

2

/ N

2

gassing (optional)

If you intend to run the unit with an oxygen content above 21%, connect an oxygen cylin-

der.

If you intend to run the unit with an oxygen content less than 21%, connect a nitrogen cylin-

der.

To deactivate the oxygen control, set the nominal value to 21.0% (average oxygen content

of ambient atmosphere).

RS 232 interface

Serial interface for computer-aided acquisition and documentation of critical operating parameters

(temperature, CO

2

, relative humidity, error codes, etc.). The RS 232 interface can connect a single

unit in combination with the "Kelvilog"

software package, and can be expanded to connect 31

units with the "Netcontrol"

hard- and software package.

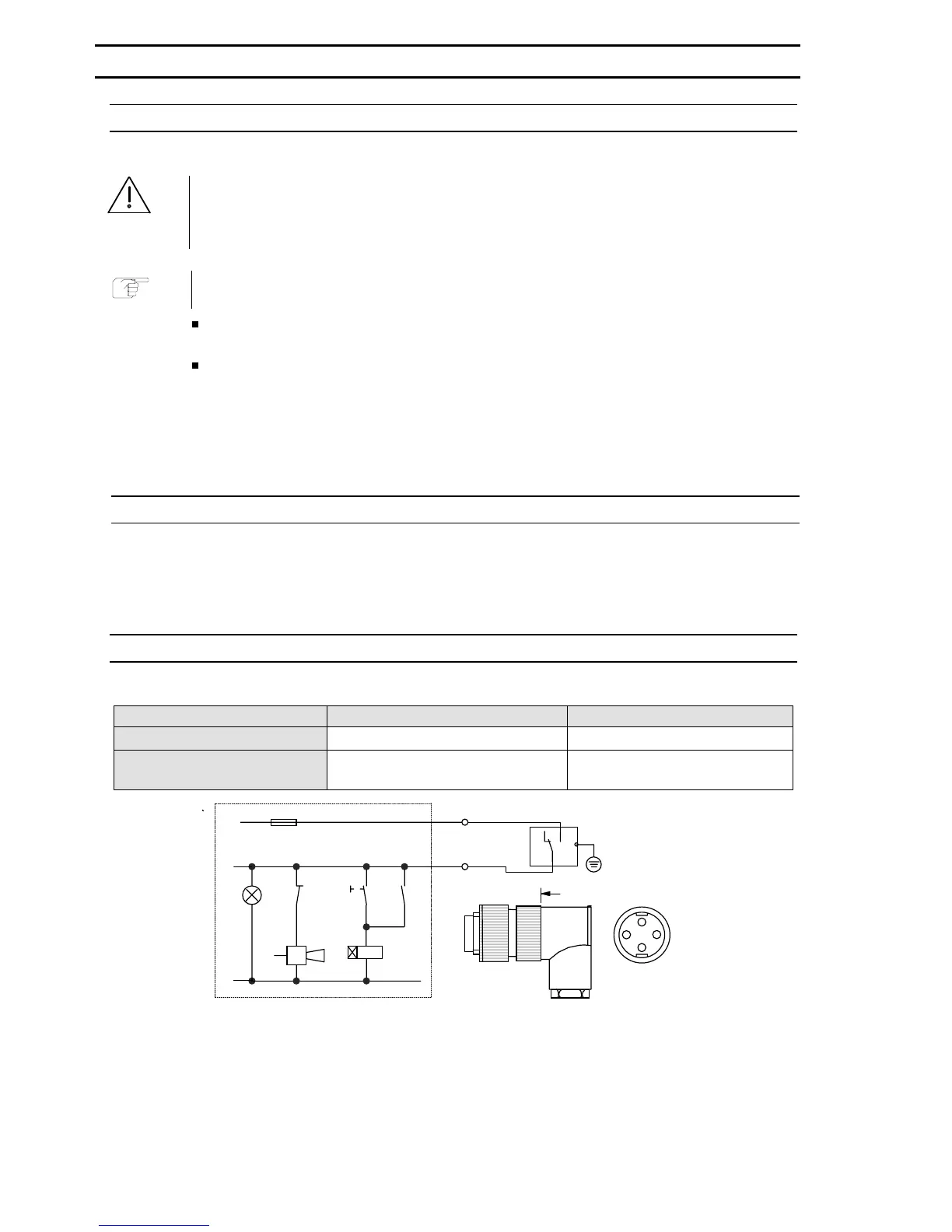

"Potential - free contact" connection

The "Potential-free contact" (1 changeover contact) is rated for the following circuits:

Circuit Voltage Fuse to be installed by customer

Mains-operated circuits max. 250 V AC max. 6 A

SELV / SELV - E - circuits

(cf. VDE 0100 Part 410)

25/50 V AC

60/120 V DC

max. 2/1 A

max. 1/0.5 A

Fig. 3 : Application example of "Potential - free contact" connection

31

2

X

View X

PE

3

1

2

L

F1x

T2A

H1x

Kx

S1x

Kx

H2x

Kx

A1

A2

N

1s

4. SETUP AND INSTALLATION

12/43

50 079 041

Loading...

Loading...