13

ZIP 22

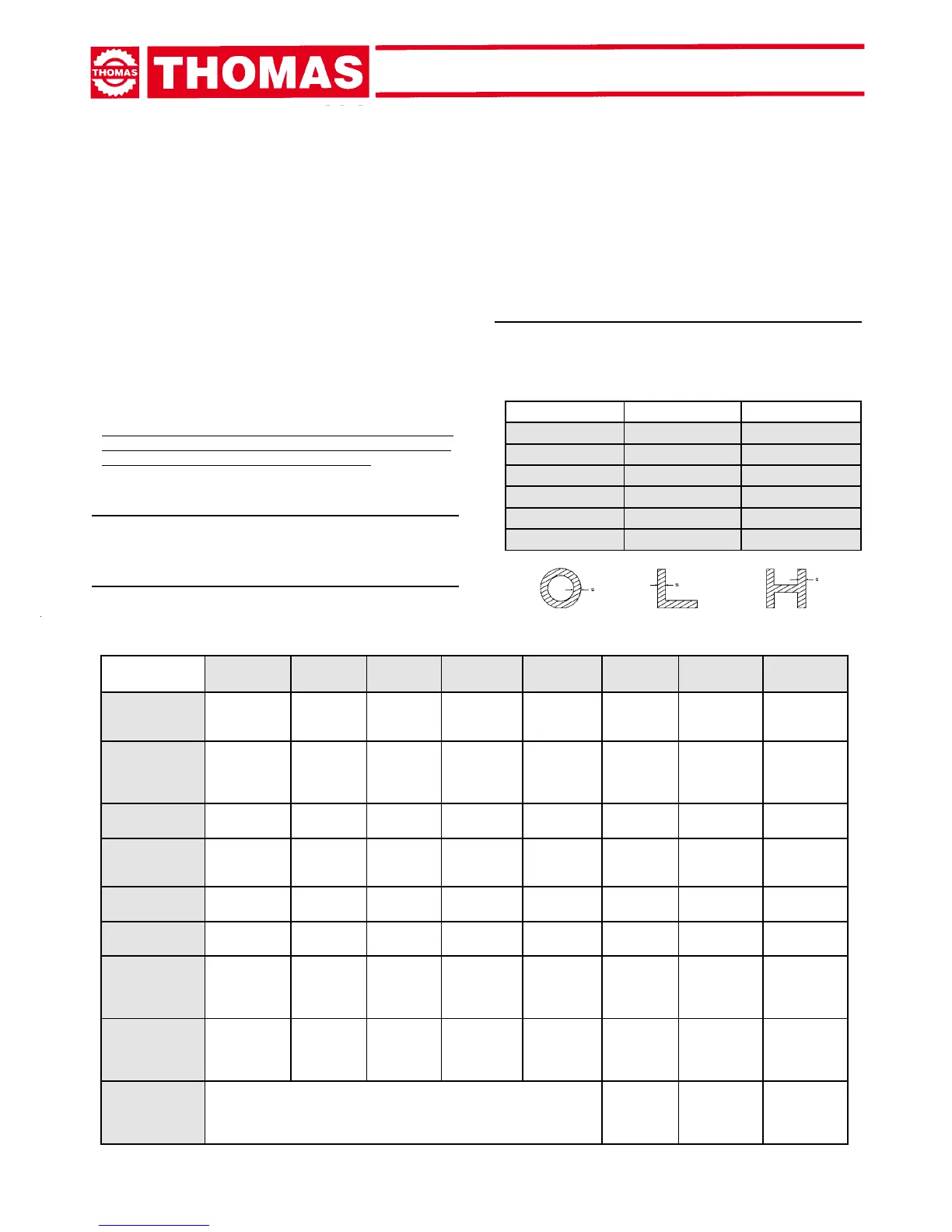

Thickness in mm (S) Continuous Toothing Alternate Toothing

up to 1,5mm Z=14 Z=10/14

from 1 to 2 Z=8 Z=8/12

from 2 to 3 Z=6 Z=6/10

from 3 to 5 Z=6 Z=5/8

from 4 to 6 Z=6 Z=4/6

more than 6 Z=4 Z=4/6

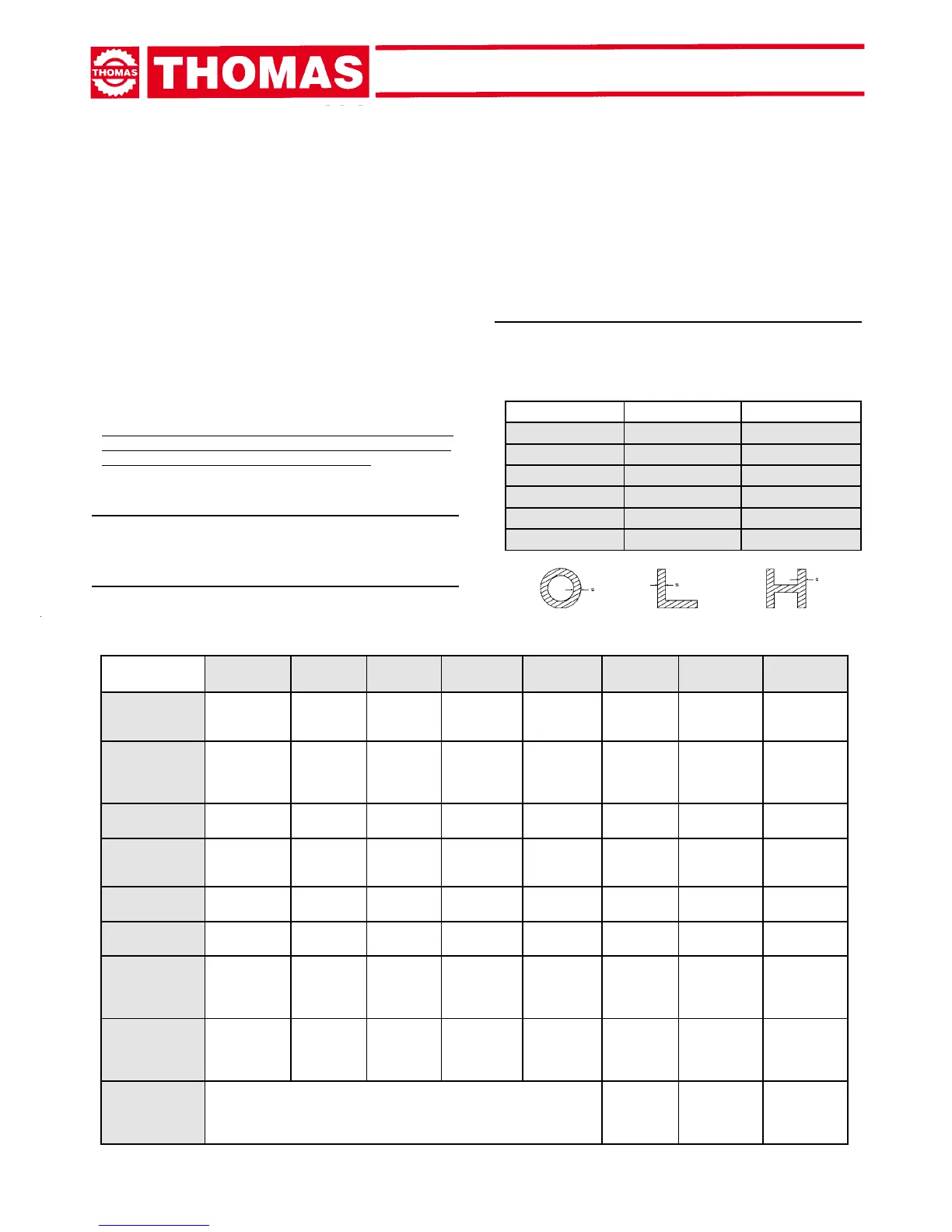

Standard /

Materialien

(I)

UNI

(D)

DIN

(F)

AFNOR

(GB)

SB

USA

AISI-SAE

Brinell

Härte HB

Rockwell

Härte HRB

R=N/mm2

Construction

steel

Fe360 Fe430

Fe510

St37 St44

St52

E24 E28

E36

43 50 116 148 180 67 80 88 360÷480

430÷560

510÷660

Non Alloy Steel C20 C40 C50

C60

CK20 CK40

CK50 CK60

XC20

XC42H1

XC55

060 A 20 060

A 40 060

A 62

1020 1040

1050 1060

198 198

202 202

93 93 94 94 540÷690

700÷840

760÷900

830÷980

Spring Steel 50CrV4

60SiCr8

50CrV4

60SiCr7

50CV4 735 A 50 6150 9262 207 224 95 98 1140÷1330

1220÷1400

Alloy Steel for

Hardening

35CrMo4

39NiCrMo4

41CrAlMo7

34CrMo4

36CrNiMo4

41CrAlMo7

35CD4

39NCD4

40CADG12

708 A 37 905

M 39

4135 9840 220 228

232

98 99 100 780÷930

880÷1080

930÷1130

Alloy Einsatzstahl 18NiCrMo7

20NiCrMo2

21NiCrMo2 20NCD7

20NCD2

En 325 805

H 20

4320 4315 232 224 100 98 760÷1030

690÷980

Steel for Bea-

rings

100Cr6 100Cr6 100C6 534 A 99 52100 207 95 690÷980

Tool Steel 52NiCrMo-

KU C100KU

X210Cr13KU

58SiMo8KU

56NiCrMo

C100W1

X2210Cr12

Z200C12

Y60SC7

BS 1 BD2 -

BD3

S-1 D6 - D3

S5

244 212

252 244

102 96 103

102

800÷1030

710÷980

820÷1060

800÷1030

Stainless Steel X12Cr13

X5CrNi1810

X8CrNi1910

X8CrNiMo171

4001 4301

4401

Z5CN18.09

Z6CDN17.1

304 C 12

316 S 16

410 304 316 202 94 670÷885

590÷685

540÷685

490÷685

Kupferlegierung

Spezialmessing

Bronze

Aluminium-Kupferlegierungen G-CuAl11Fe4Ni4 UNI 5275 Spezialmessing

mit Mangan/Silizium G-CuZn36Si1Pb1 UNI 5038 Manganbronze SAE43 -

SAE430 Phosphorbronze G-CuSn12 UNI 7013/2a

220 140

120 100

98 77 69 56,5 620÷885

375÷440

320÷410

265÷314

Since the aim is to obtain excellent cutting quality, the various

parameters such as hardness of the material, shape and

thickness, transverse cutting section of the part to be cut,

selection of the type of cutting blade, cutting speed and

control of saw frame lowering.Thesespecicationsmust

therefore be harmoniously combined in a single operating

condition according to practical considerations and common

sense, so as to achieve an optimum condition that does

not require countless operations to prepare the machine

when there are many variations in the job to be performed.

The various problems that crop up from time to time will be

solved more easily if the operator has a good knoledge of

thesespecications.

WE THEREFORE RECOMMEND YOU TO ALWAYS USE

GENUINE "THOMAS" SPARE BLADES THAT GUARANTEE

SUPERIOR QUALITY AND PERFORMANCE.

9.1 - Denition of materials

The table at the foot of the page lists the characteristics of the

materials to be cut, so as to choose the right tool to use.

9.2 - Selecting blade

First of all the pitch of the teeth must be chosen, in the other

words, the number of teeth per inch (25,4 mm) suitable for the

9

MATERIAL

CLASSIFICATION AND

CHOICE OF TOOL

material to be cut, according to these criteria:

- partswithathinand/orvariablesectionsuchasproles,pipes

and plate, need close toothing, so that the number of teeth used

simultaneouslyincuttingisfrom3to6;

- parts with large transverse sections and solid sections need

widely spaced toothing to allow for the greater volume of the

chipsandbettertoothpenetration;

- parts made of soft material or plastic (light alloys, mild bronze,

teon,wood,etc.)alsorequirewidelyspacedtoothing;

- pieces cut in bundles require combo tooth design.

9.3 - Teeth pitch

As already stated, this depends on the following factors:

- hardness of the material

- dimensions of the section

- thickness of the wall.

Loading...

Loading...