15

ZIP 22

Set

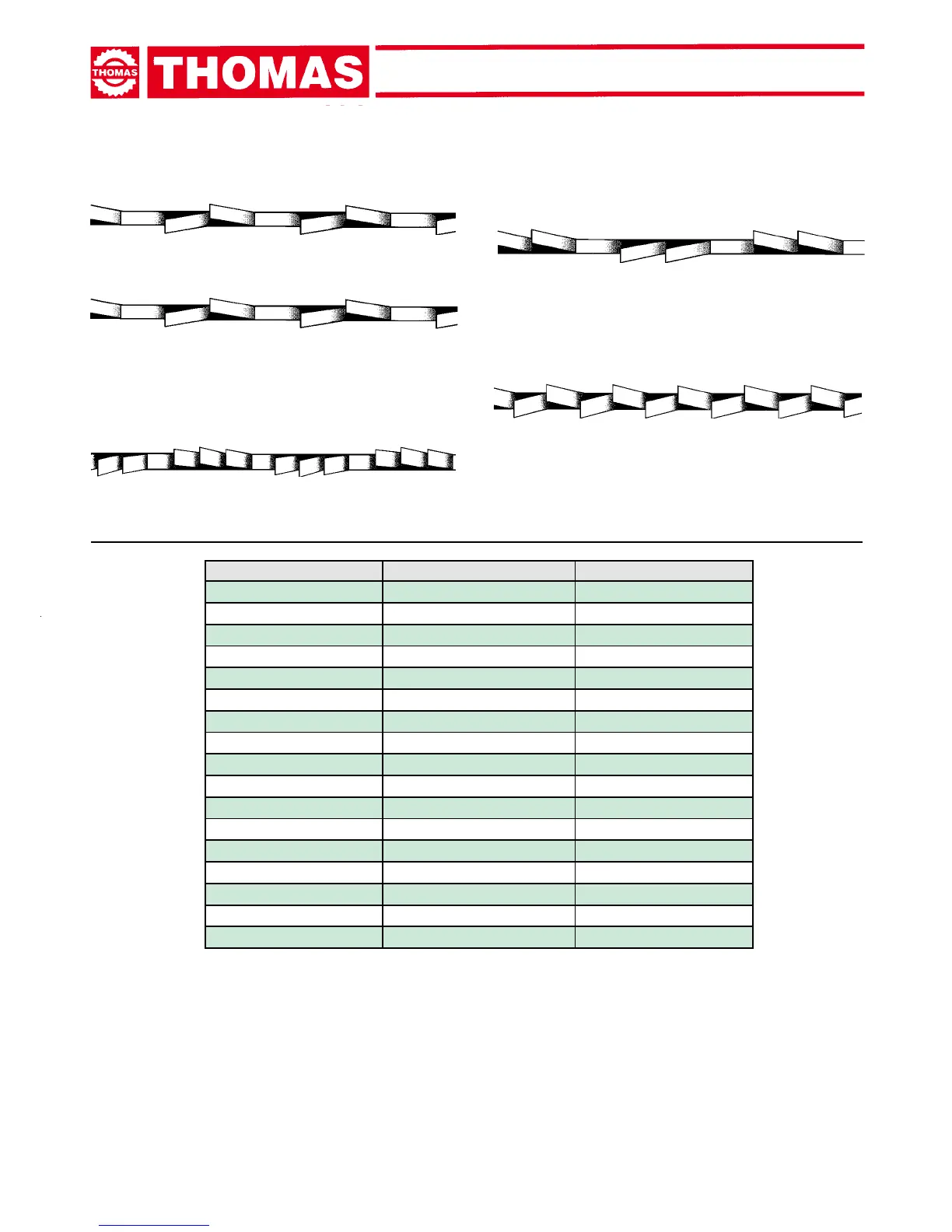

Saw teeth bent out of the plane of the saw body, resulting in a

wide cut in the workpiece.

REGULAR OR RAKER SET: Cutting teeth right and left, alter-

nated by a straight tooth.

Of general use for materials with dimensions superior to 5 mm.

Used for the cutting of steel, castings and hard nonferrous ma-

terials.

WAVY SET: Set in smooth waves.

Thissetisassociatedwithveryneteethanditismainlyused

for the cutting of pipes and thin section bars (from 1 to 3 mm).

ALTERNATE SET (IN GROUPS): Groups of cutting teeth right

and left, alternated by a straight tooth.

Thissetisassociatedwithveryneteethanditisusedforex-

tremely thin materials (less than 1 mm).

ALTERNATE SET (INDIVIDUAL TEETH): Cutting teeth right

and left.

This set is used for the cutting of nonferrous soft materials,

plastics and wood.

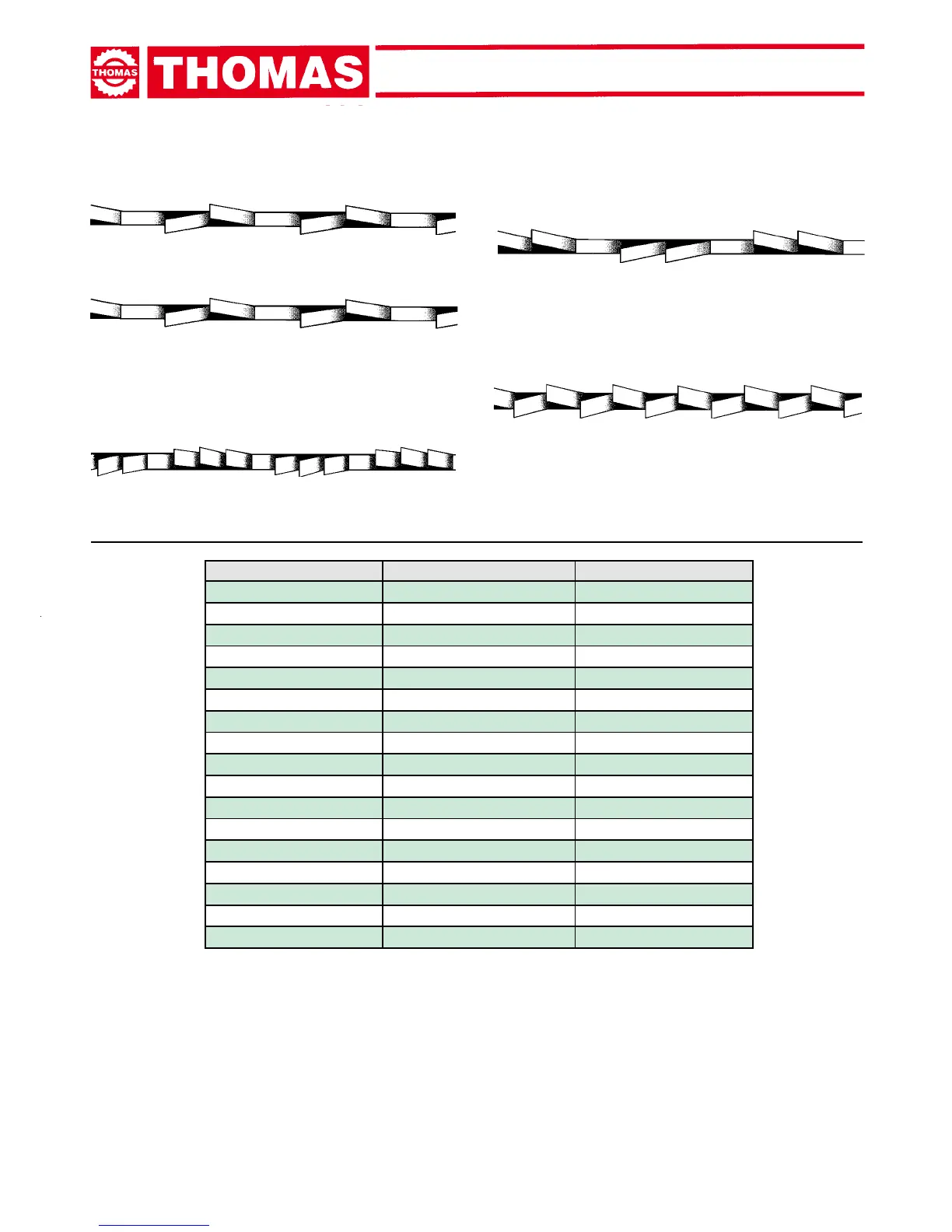

9.7.1 - CUTTING PARAMETERS

Steel Type Cutting Speed m/min. Coolant Liquid

Construction Steel 60÷80 m/min Oil Emulsion

Einsatzstahl 40÷50 m/min Oil Emulsion

Non Alloy Steel 40÷60 m/min Oil Emulsion

Vergüteter Stahl 40÷50 m/min Oil Emulsion

Steel for Bearings 40÷60 m/min Oil Emulsion

Steel for Springs 40÷60 m/min Oil Emulsion

Tool Steel 30÷40 m/min Oil Emulsion

Steel for Valves 35÷50 m/min Oil Emulsion

Stainless Steel 30÷40 m/min Oil Emulsion

Cast-Iron 20÷40 m/min Oil Emulsion

Stahleisen 40÷60 m/min Oil Emulsion

Aluminium 80÷600 m/min Kerosene

Bronze 70÷120 m/min Oil Emulsion

Hartbronze 30÷60 m/min Oil Emulsion

Messing 70÷350 m/min Oil Emulsion

Kupfer 50÷720 m/min Oil Emulsion

Loading...

Loading...