11

ZIP 22

7.2 - Blade guide blocks

The blade is guided by means of adjustable rollers set in place

during inspection as per the thickness of the blade with minimum

playasshowninthegure.

In case the blade needs to be replaced, make sure to always

install 0.9 mm thick blades for which the blade guide rollers have

been adjusted. In the case of toothed blades with different thick-

nesses adjustment should be carried out as follows:

- Loosen the nuts ( 1 ) and rotate the pin ( 2 ) widening the pas-

sage between the rollers.

- Mount the new blade, place the rollers and rotate the pin ( 2 ) leaving

0,04mm clear to allow the blade sliding smoothely. Secure the Nut ( 1 ).

- Make sure that 0,2-0,3mm clear between the blade back and

theroller(4);Justincase,loosenthescrewsthatfastensthe

heads(5)andcarryoutnaladjustment.

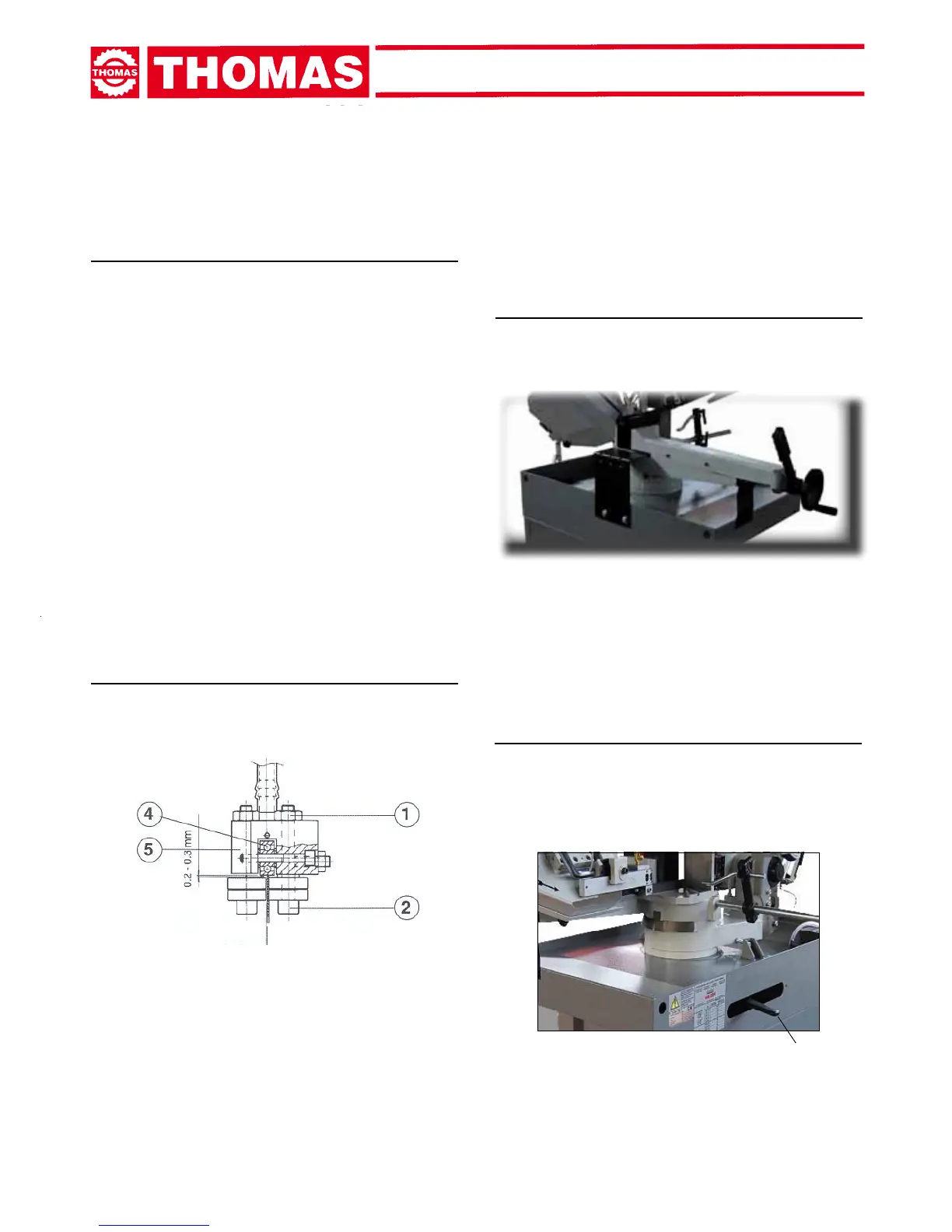

7.3 - Vice

- Thedevicedoesnotrequireanyparticularadjustment;incase

of excess play of the sliding guide, tighten slide screw more.

- Place material to be cut in the vice. Close jaws against piece,

keeping a distance of approx. 3 - 4 mm then clamp with lever.

REGULATING

THE MACHINE

7.1 - Blade tension assembly

-Turn clockwise the handwheel to put the blade under tension ac-

cording to the scale ( 10 ) showing 20, 30 and 35.000 psi (pounds

per square inch). Bi-metal M42 blades need to be tensioned to

30-35.000 psi, whilst for Carbon blades the tension should be

20.000 psi. At the end of each working day, it is reccomended

to loose the blade tension to a minimum. This will preserve the

exibilityofthebladeandguaranteelongerdurability.

7

6

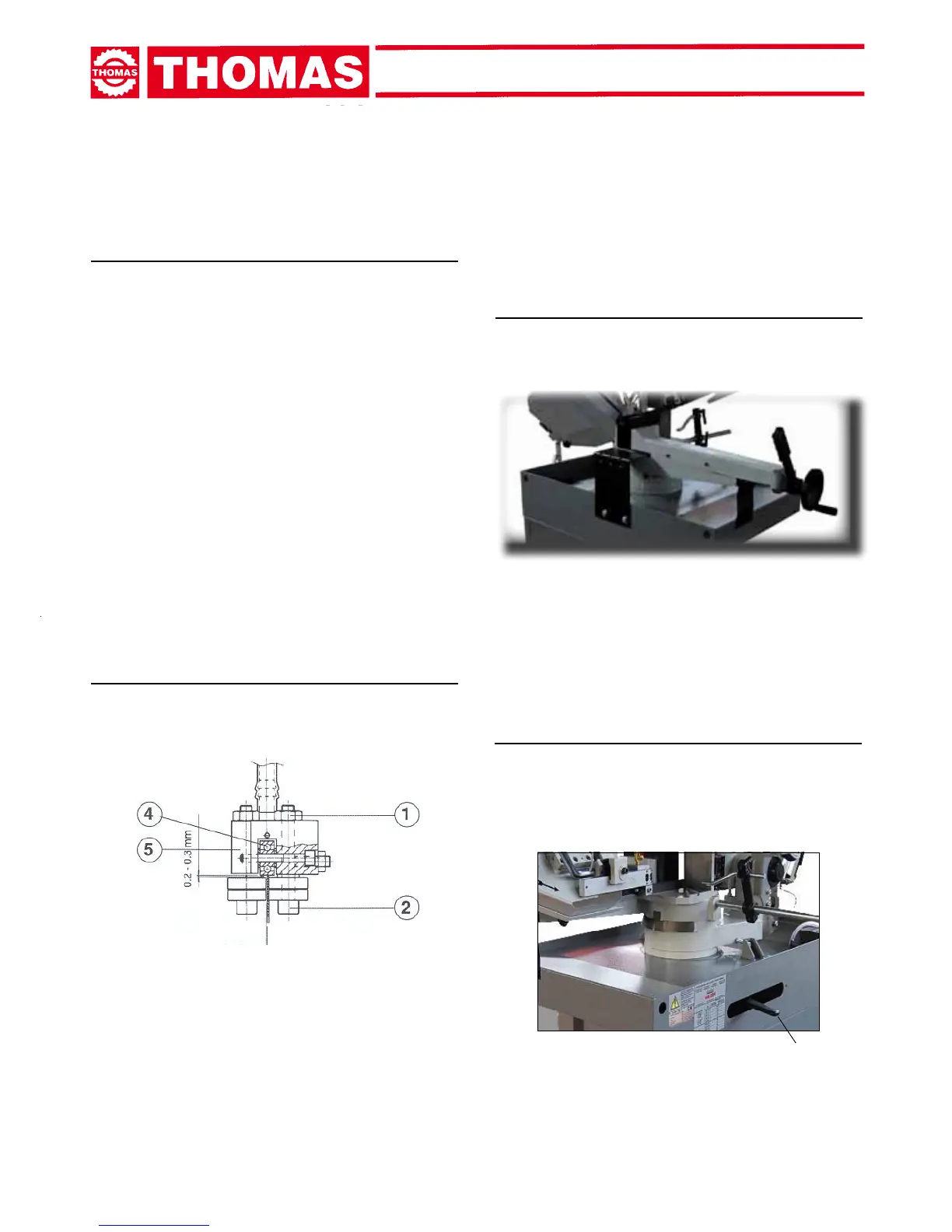

7.5 - Cutting angle adjustment

- Unlock lever (6) and rotate the saw frame arm until you

reach mechanical stop and check if the index corres-

pondsto60°;ifnotoperateonthesetscrewstomake

measures meet.

Loading...

Loading...