8

ZIP 22

5

R = L1

S = L2

T = L3

PE = GND

600mm

385mm

740mm

ø 10,5mm

OuterProle

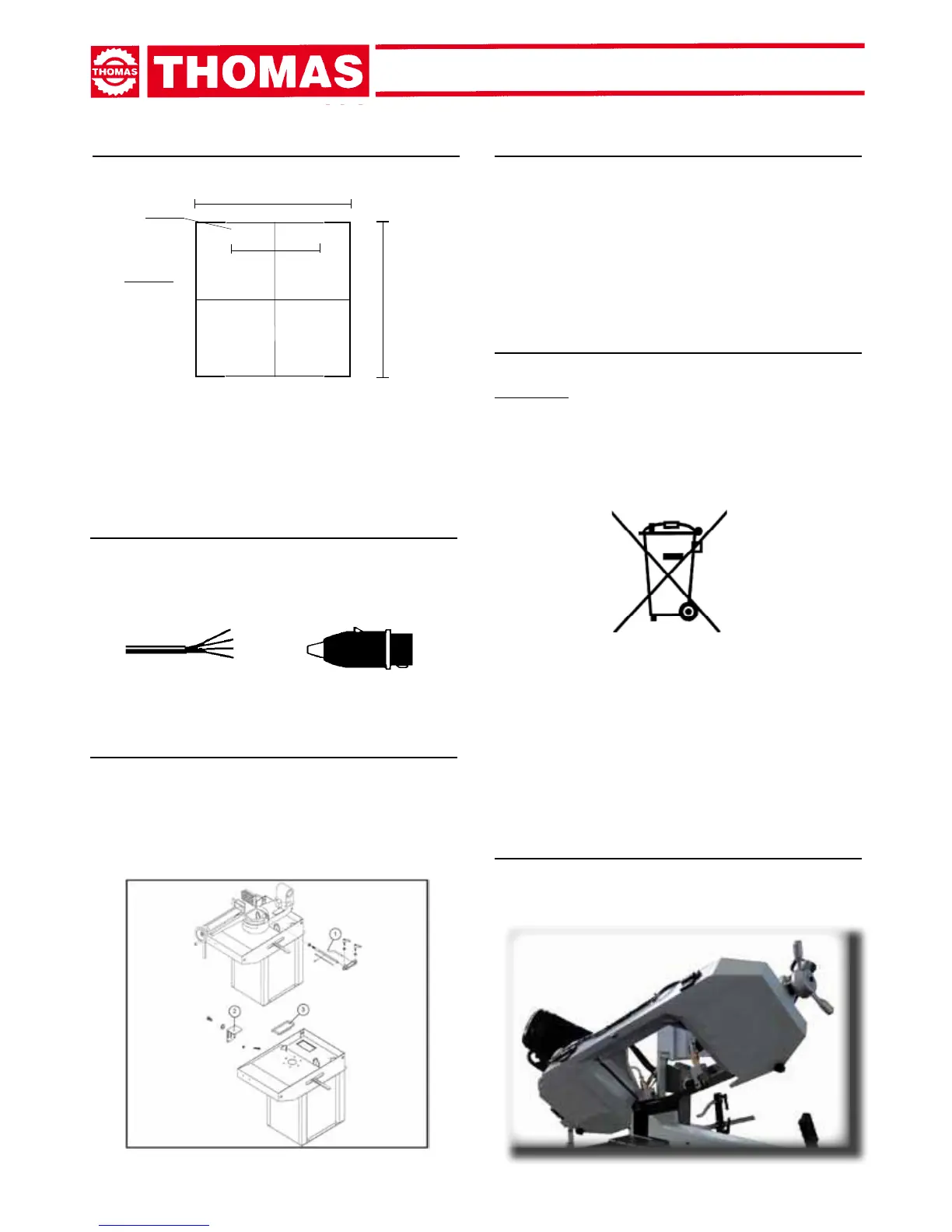

4.4 - Anchoring the machine

- Positionthe machineona rmcementoor,maintaining,at

therear,aminimumdistanceof800mmfromthewall;anchor

it to the ground as shown in the diagram, using screws and

expansion plugs or tie rods sunk in cement, ensuring that it is

sitting level.

4.5 - Instructions for electrical connection

- The machine is not provided with an electric plug, so the cus-

tomermusttasuitableoneforhisownworkingconditions:

1 - WIRING DIAGRAM FOR 4-WIRE SYSTEM FOR THREE-

PHASE MACHINE - SOCKET FOR A 16A PLUG

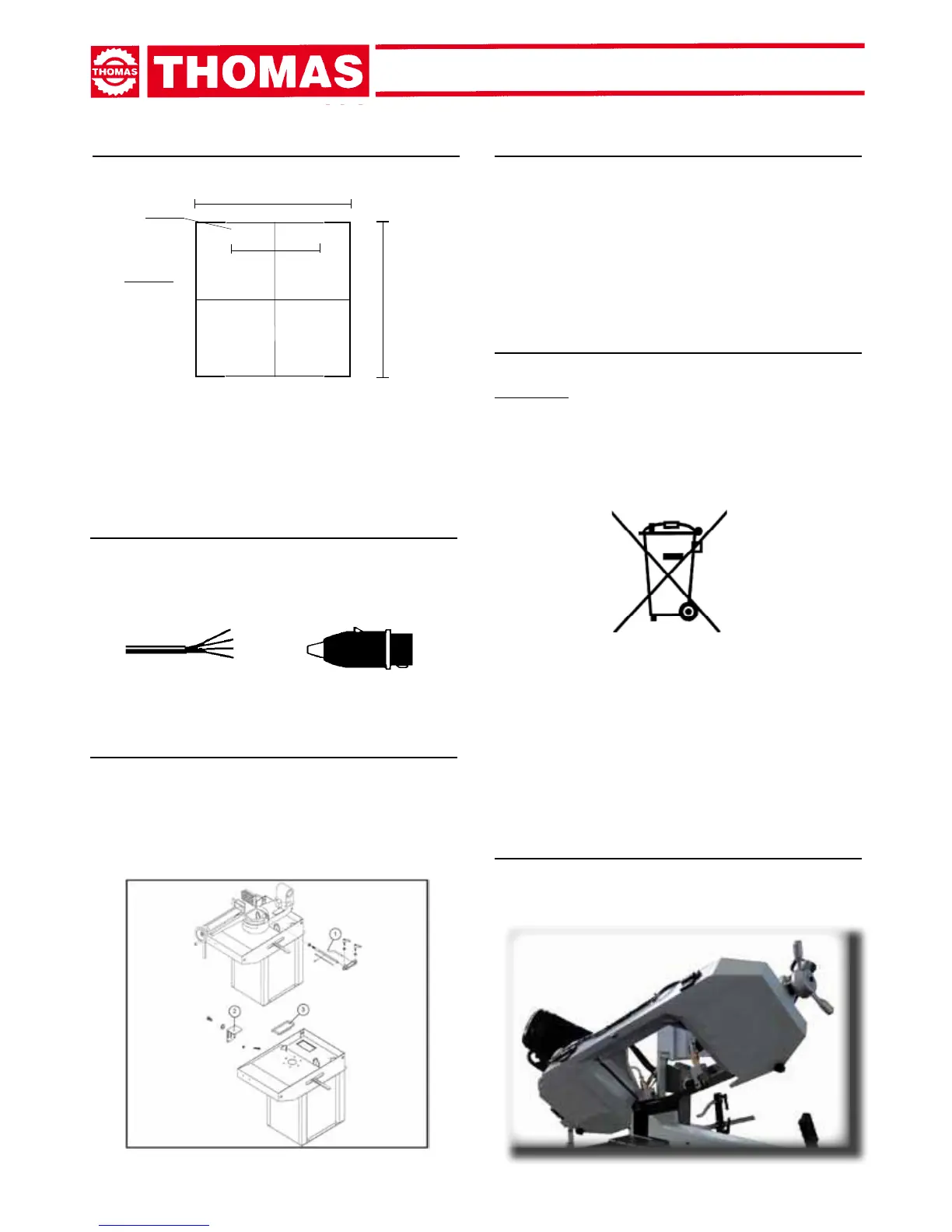

4.6 - Instructions for assembly of the loose parts

and accessories

See following picture

1) Mount Bar-Stop n.1.

2) Material-Support n.2 should be set according to working table

levelandxedtotheposition.

3) Splash-Guard n.3 should be set in place to avoid coolant liquid

droppingdowntotheoor.

4.7 - Disactivating the machine

- If the sawing machine is to be out of use for a long period, it is

advisable to proceed as follows:

1) detach the plug from the electric supply panel

2) loosen blade

3) release the arch return spring

4) empty the coolant tank

5) carefully clean and grease the machine

6) if necessary, cover the machine.

4.8 - Dismantling

(because of deterioration and/or obsolescence)

General rules

ATTENTION: This symbol indicates that this product shall not be

treated as household waste. Instead it should be handed over

to the applicable collection point for the recycling of electrical

equipment. For more detailed information about recycling of this

product,pleasecontactyourlocalCivicOfce,yourhousehold

waste disposal service or the shop where you purchased the

product.

MACHINE FUNCTIONAL

PARTS

5.1 - Operating head or sawframe

- Machine part consisting of the members that transfer the motion

(gearmotor,ywheels),andtension/guide(blade-guides,blade

tension slide) and sawframe dowfeed control.

Loading...

Loading...