Thomson

Thomson Electrak

®

LL Actuator - Installation Manual - 2020-1110

Installation

4.5 Electrical installation

4.5.1 General notes

• Make sure the leads/cables leading to the motor can handle the maximum motor current.

• An emergency stop is recommended to reduce the chance of a crushing hazard.

• Never work on the actuator or the wiring with the power switched on!

4.5.2 Fuse size

Protect the actuator and the wiring by using a slow blow fuse between the actuator and the power source.

4.5.3 Electrical connections

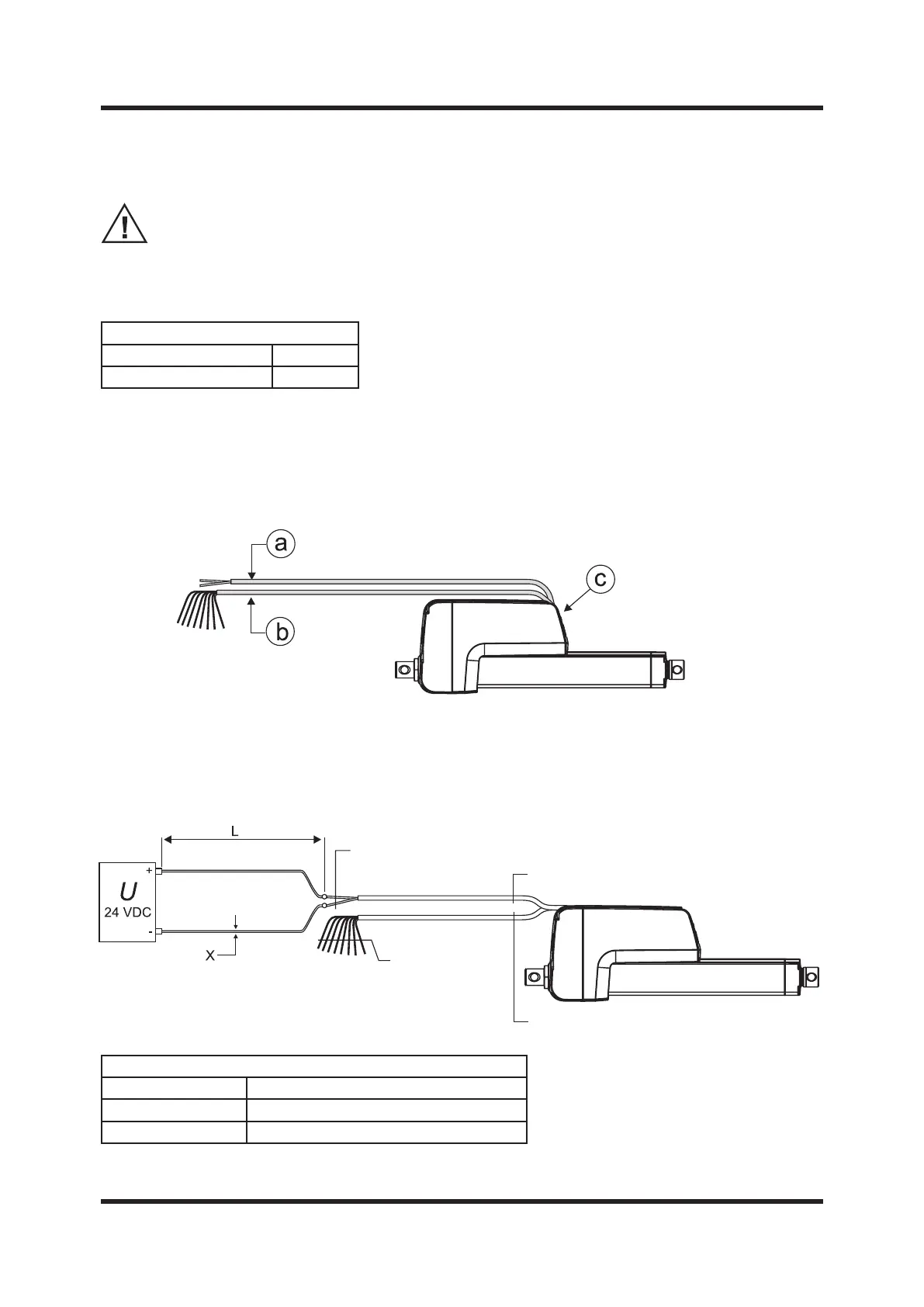

The actuator is always supplied with a power cable (a). Depending on which control option was selected, it

can also have a signal cable (b). The cable(s) have ying leads in one end for customer connections. In the

other end the cable(s) are integrated in to the cable connector cover plate (c) (section 4.4.4). The plug in

connector allows replacing the actuator without disconnecting the ying leads.

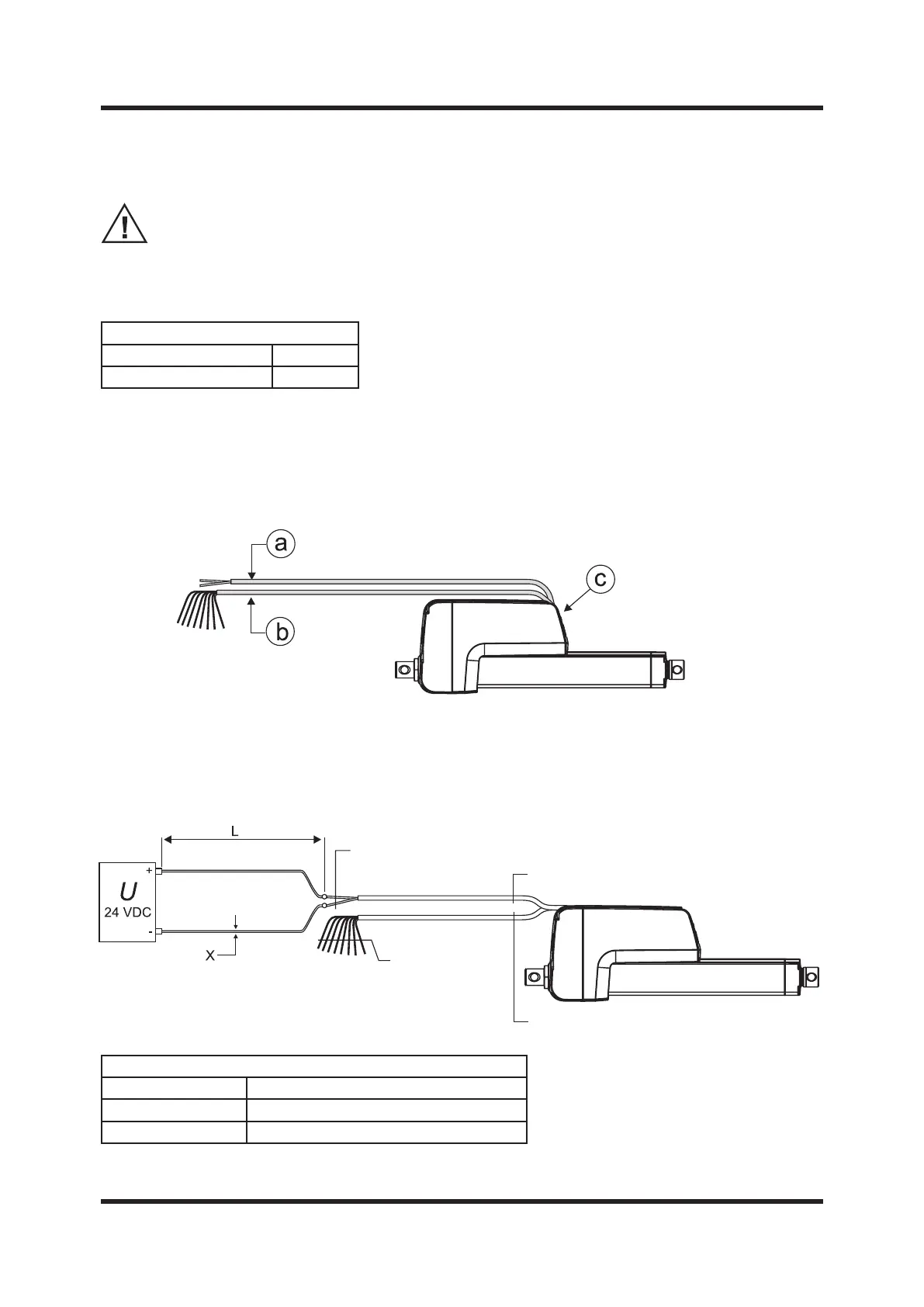

4.5.4 Lead cross sections

To avoid malfunction due to voltage drop the cross section of the leads between the actuator power

cable leads and the power source must be of sucient size. For longer cables than stated in the table,

calculations based on the supply voltage, the current draw, the length of the cables and the ambient

temperature must be done.

Power Lead Cross Sections

Length of cable (L) Min. allowed cross section (X)

0 - 4 m 1.5 mm

2

[AWG 16]

4 - 10 m 2.5 mm

2

[AWG 14]

Recommended Fuse Size

Actuator supply voltage Fuse size

24 Vdc 20 A

1.5 mm

2

[AWG 16]

Power cable

Signal cable

X

0.5 mm

2

[AWG 20]

Loading...

Loading...