LDC401 & LDC401A Automated Cleavers Chapter 7: Cleaving

Page 20 TTN100064-D02

The Micrometer Backstop acts as a backing for the fiber during the Cleave Process. When using the Micrometer

Backstop, it is possible to reduce the tension applied to the fiber because the Micrometer Backstop will prevent the

fiber from flexing when struck by the blade to produce a longer initial scribe. The longer initial scribe causes the

fiber to cleave, despite the relatively low tension. Since the tension is lower, the crack propagates slowly with little

driving force, and a smoother cleave surface results. The Micrometer Backstop may be used in conjunction with the

“Subcritical Process” to produce cleaves with very good end face quality.

A general rule to follow when using the Micrometer Backstop is that the Cleave Tension should initially be lowered

to 85% of the Auto Parameter value that Tablet Controller recommends for the diameter of the part. Adjust the

tension based upon visual inspection of the end face. Increase the tension if there is no end face damage but the

cleave has an angle. Decrease the tension if there is end face damage but no angle. Do not go below 60% of the

Auto Parameter value or severe blade damage may result.

Figure 20 Using an Eye Loupe to Check that the Micrometer Backstop just Touches the Fiber

To use the Micrometer Backstop, load the fiber in to the unit in the normal way, but do not initiate a cleave

immediately. Rotate the micrometer until it just contacts the fiber. It is a good idea to use a 10X eye loupe to make

sure that the Micrometer Backstop just barely touches the fiber (see Figure 20). After the Micrometer Backstop is

set, initiate the cleave as per standard procedure. Be careful not to flex the fiber forwards, or the results will be

poorer than not using the micrometer at all!

After cleaving, back the micrometer away from the cleaved fiber prior to unloading. This will ensure that the fiber

does not contact the micrometer during unloading.

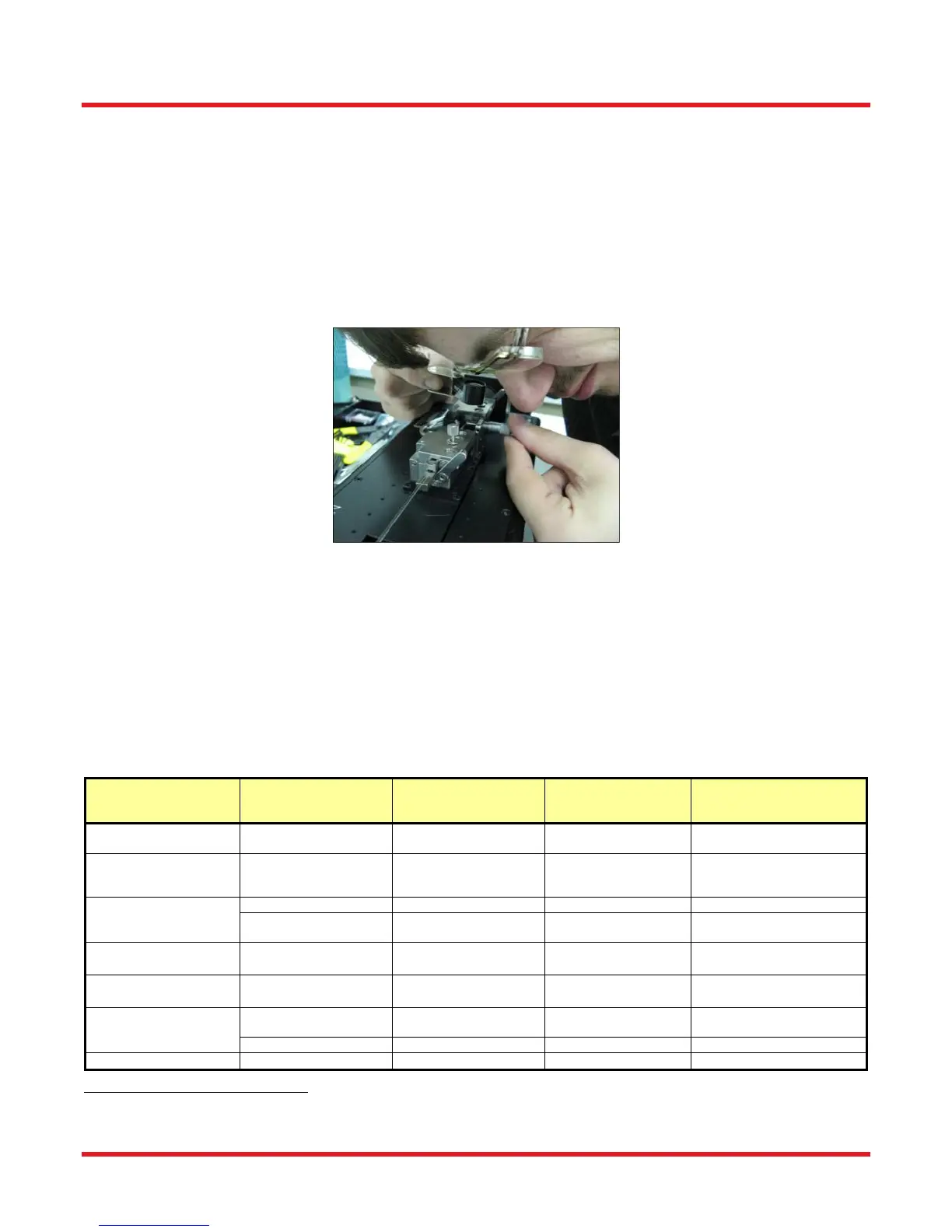

The following chart offers guidelines for when to use the Subcritical Process and the Micrometer Backstop.

Process Selection Chart

Fiber Type

Cleave

Type

Standard

Process

SubCritical

Process

Micrometer

Backstop

Cladding <Ø800 µm

Flat or

Angled

1

- -

Cladding ≥Ø800 µm

Flat or

Angled

1

May be Necessary

Use if the Blade is Pushing

the Fiber Forwards without

Cleaving

Multimode

Flat

- -

Angled

1

-

Use if Fiber Cladding is

>Ø400 µm

Thick-Walled

Capillary Tubing

2

Flat or

Angled

1

- -

Thin-Walled

Capillary Tubing

3

Flat or

Angled

1

-

PM

Flat

Use if Fiber Cladding is

≤Ø400 µm

Use if Fiber Cladding is

>Ø400 µm

Angled -

PCF

Flat or Angled

1

-

1

Only the LDC401A can be used to produce angled cleaves.

2

Wall thickness is at least 10% of the diameter.

3

Wall thickness is less than 10% of the diameter.

Loading...

Loading...