LDC401 & LDC401A Automated Cleavers Chapter 9: Controlling the LDC401 and LDC401A

Rev B, July 19, 2017 Page 45

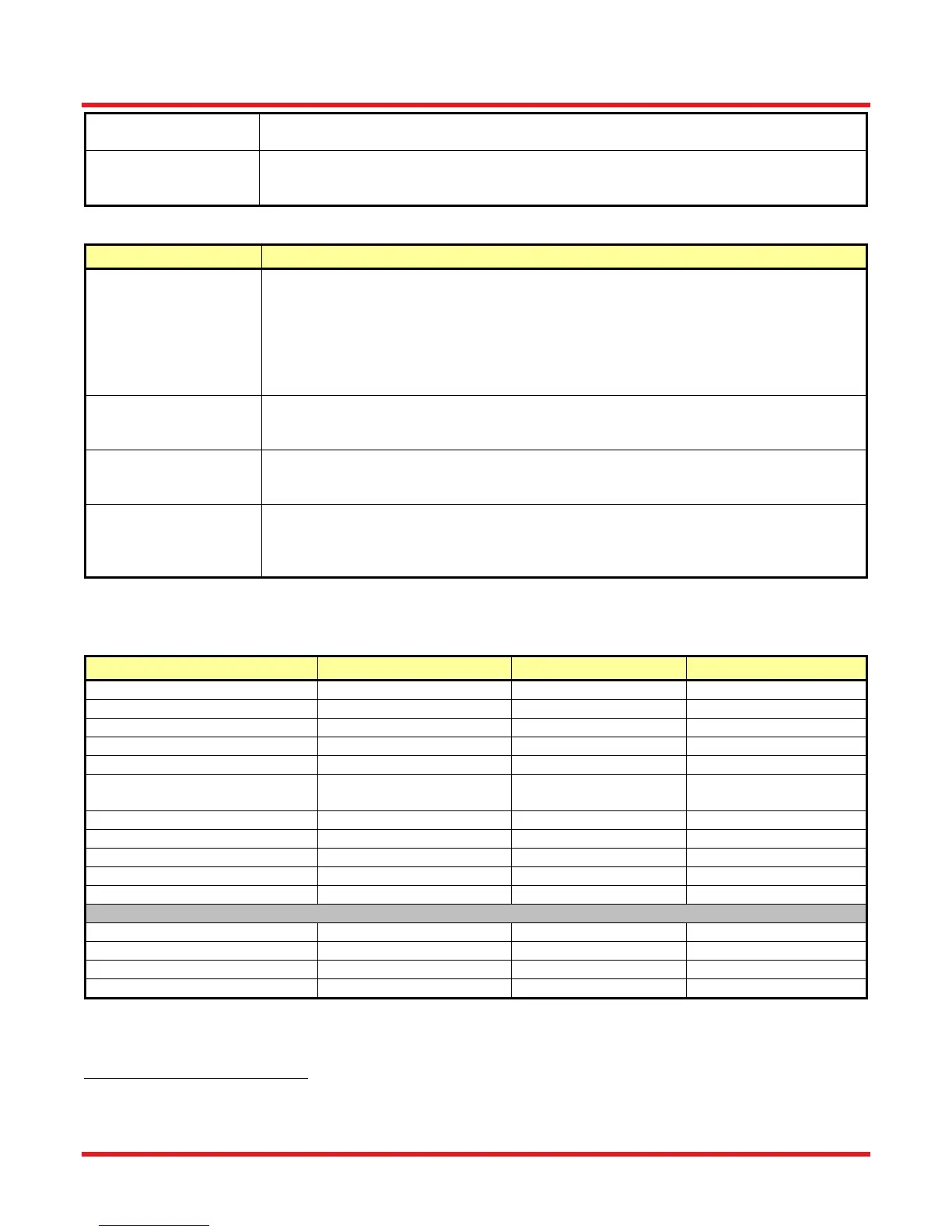

Coating Diameter

This parameter is used by the Insert Selection Tool to determine the optimum insert

choice for the left FHB. The coating diameter is also displayed in the Cleave Widget.

Backstop Position

Backstop Position is displayed in the Cleave Widget and provides a visual clue that

the backstop should be set and its approximate value. A value of 7mm is typically

considered to mean ‘unused’.

The following Parameters are required by the sub-critical process.

Parameter Description

Re-Tension Level

(grams)

This parameter is the additional load, in grams, applied axially to the fiber after the

Post-Scribe Pause and after successive Re-Tension Pauses. The optimal Re-

Tension Level setting is dependent upon the effective cross sectional area, material

properties and type of fiber as well as scribe size. Experimentation will be required to

optimize the Re-tension Level, but it will typically be less than 50 grams. The settings

are programmed into the Tablet Controller in grams. Possible settings correspond to

a range of tensions from 9.8 mN (0.0022 lbs) to 0.98 N (0.22 lbs).

Re-Tension Limit

This parameter is the percentage of original (starting) tension that will be added to

the original (starting) tension after the Post-scribe Pause through all the successive

re-tensioning steps.

Post-Scribe Pause

(seconds)

This parameter is the pause, in seconds, between the last blade oscillation and the

first re-tension. Typically, the Post-Scribe Pause is set to 1-3 seconds. This is enough

time for the scribe to propagate and cleave the fiber if the scribe was too large.

Re-Tension Pause

(seconds)

This parameter is the pause in seconds between each re-tension. The optimal Re-

Tension Pause is dependent upon the effective cross sectional area, material

properties and type of fiber as well as scribe size. Experimentation will be required to

optimize the Re-Tension Pause.

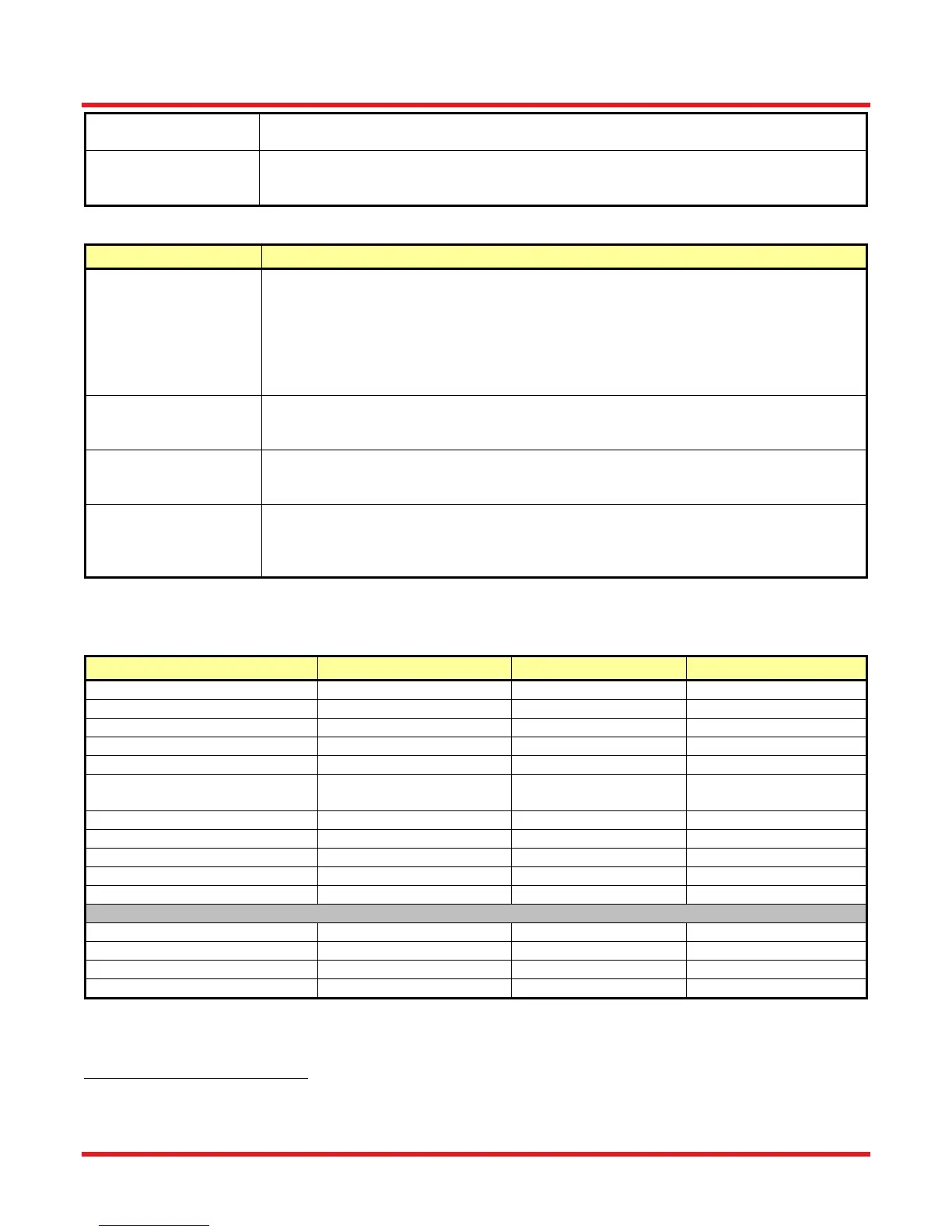

9.9. Parameter Limit

Minimum and maximum Parameter values permitted by the Tablet Controller are given below.

Parameter Default Min Max

Fiber Diameter

Fiber Size Dependent 10 μm 1500 μm

Cleave Tension

7

Fiber Size Dependent 1 g 6500 g

Pre-Cleave Advance

Fiber Size Dependent 200 Steps 400 Steps

FHB Offset

0 mm 0 mm 47 mm

Tension Velocity

60 Steps/s 4 Steps/s 200 Steps/s

Cleave Rotation Angle

(LDC401A Only)

0° 0° 180°

Cleave Oscillation Counter

60 10 250

Cleave Forward Steps

81 40 400

Cleave Reverse Steps

80 39 399

Scribe Delay

250 ms 1 ms 5000 ms

Set Blade Offset

Unit Specific Value 100 Steps 2500 Steps

Sub-Critical Process Parameters

Re-Tension Level (grams)

10 g 1 g 100 g

Post-Scribe Pause (seconds)

1.0 s 0.1 s 30.0 s

Re-Tension Pause

1.0 s 0.1 s 30.0 s

Re-Tension Limit

8

20% of Cleave Tension 1% of Cleave Tension 50% of Cleave Tension

7

These Cleavers are calibrated using standard weights, so the tension settings are programmed into the Tablet Controller in grams. This

corresponds to a range of tensions from 9.8 mN (0.0022 lbs) to 63.7 N (14.3 lbs).

8

These Cleavers are calibrated using standards weights so the tension settings are programmed into the Tablet Controller in grams. This

corresponds to a range of tensions from 9.8 mN (0.0022 lbs) to 0.98 N (0.22 lbs).

Loading...

Loading...