11

Date of Origin – 02/24/11

Updated – 02/03/20

TRAILER KINGPIN WEAR

Per Recommended SAE Standards, check King Pin for

wear across the pin neck and also the pin shoulder. In

accordance with industry standards, Timpte recommends

that the kingpin and its mounting structure be inspected

for wear and damage on a daily basis.

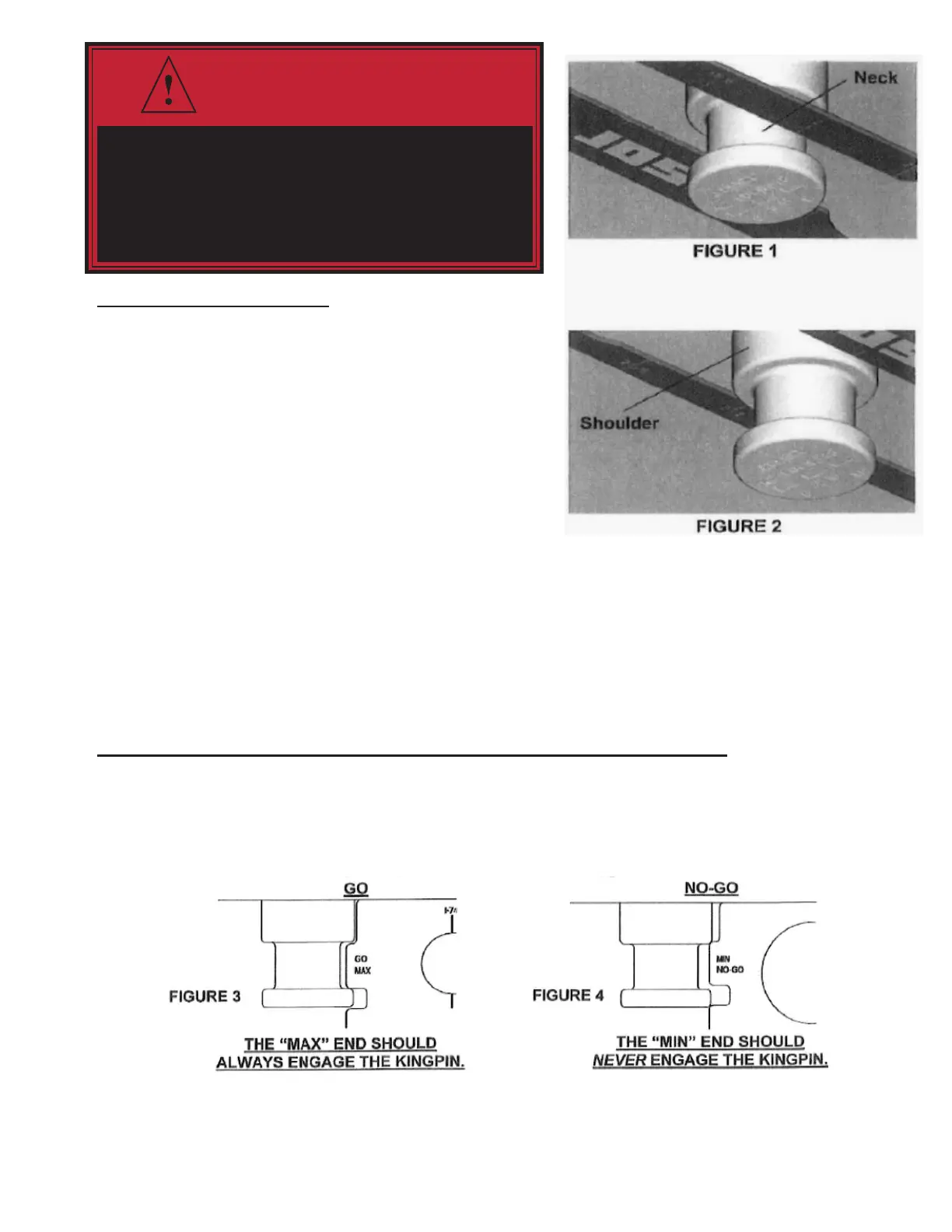

1. Measure the neck - 2”

A. Insert the head of the Kingpin through the

large opening of the small slot. Locate the

gage between the shoulder and the head of

the Kingpin.

B. Slide the gage toward the small end. The number stamped on the gage at the center

of the Kingpin indicates the dimension (see gure 1).

C. The Kingpin should be replaced when, at any orientation, the neck OD measures

1 7/8” diameter.

2. Measure the shoulder - 2-7/8”

A. Repeat the above procedure using the large slot on the shoulder of the Kingpin (see gure 2).

B. The Kingpin should be replaced when, at any orientation, the shoulder OD measures 2 ¾” diameter.

TRAILER KINGPIN TO COUPLER INTERFACE INSPECTION CRITERIA

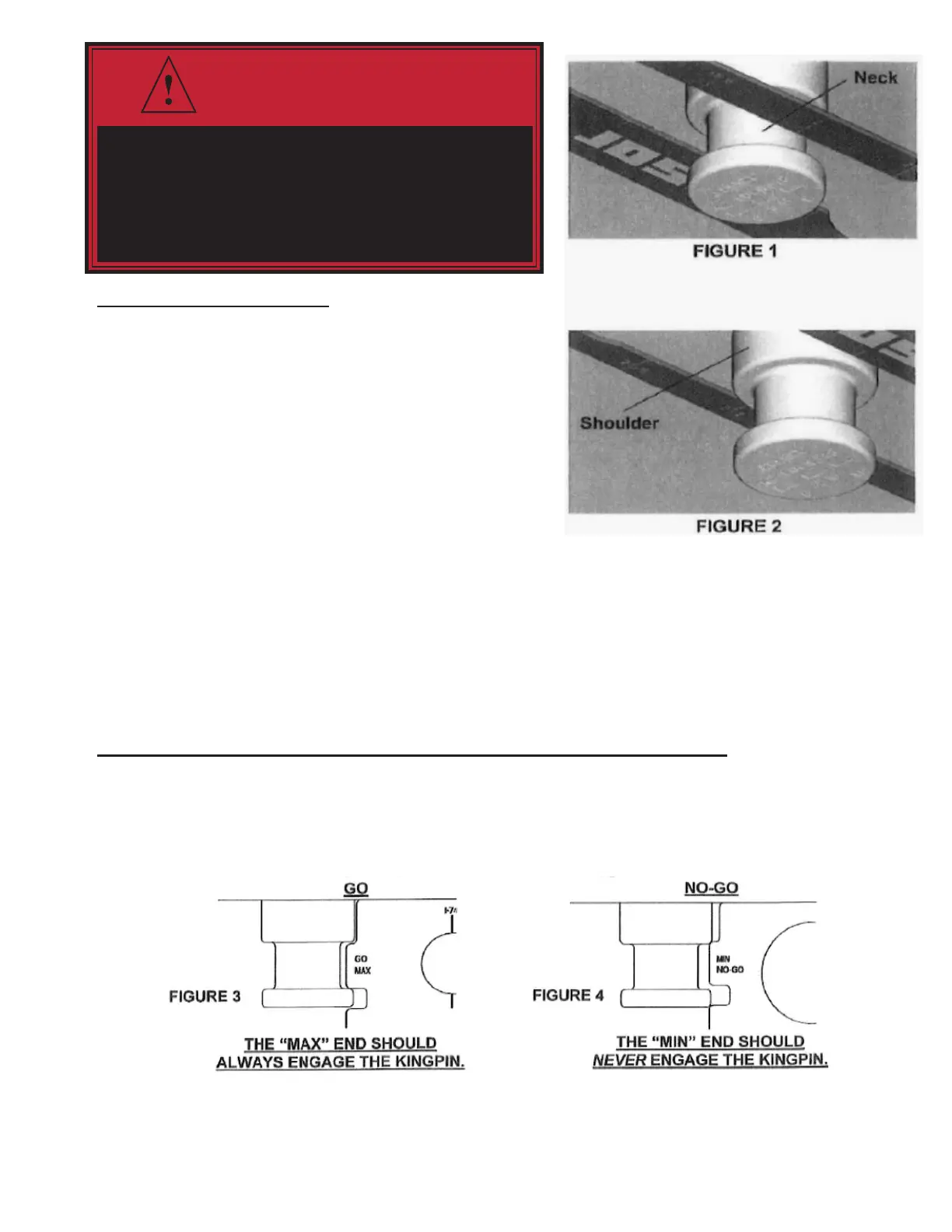

3. Measure the Kingpin length

The Kingpin is the proper length if the “MAX” end engages and the “MIN” end does not engage as shown below.

Important: Be sure to hold the gage edge at to the upper coupler. Check both the “MAX” end and the “MIN”

end as shown in gures 3 and 4.

Reference SAE J2228 standard for kingpin wear

Reference SAE J700 standard for upper coupler to kingpin interface

WARNING

TO INSURE PROPER ENGAGEMENT OF THE

KING PIN TO THE FIFTH WHEEL COUPLER,

THE KINGPIN MUST BE MAINTAINED WITHIN

RECOMMENDED SAE STANDARDS. FAILURE TO

DO SO COULD CAUSE SERIOUS INJURY OR

DEATH.

Loading...

Loading...