39

Date of Origin – 02/24/11

Updated – 02/03/20

CONVEYOR BELT TENSION AND TRACKING

To drive the conveyor belt without slippage and to track it in a proper way, a certain belt tension is

necessary. The tension applied has to be such that there is no slippage on the driving drum when the belt is started at

full load.

Belt tension or tracking needs to be done anytime the belt starts slipping on the drive pulley or the belt starts moving to

one side of the conveyor. Tensioning and tracking also needs to be done when a new belt is being installed.

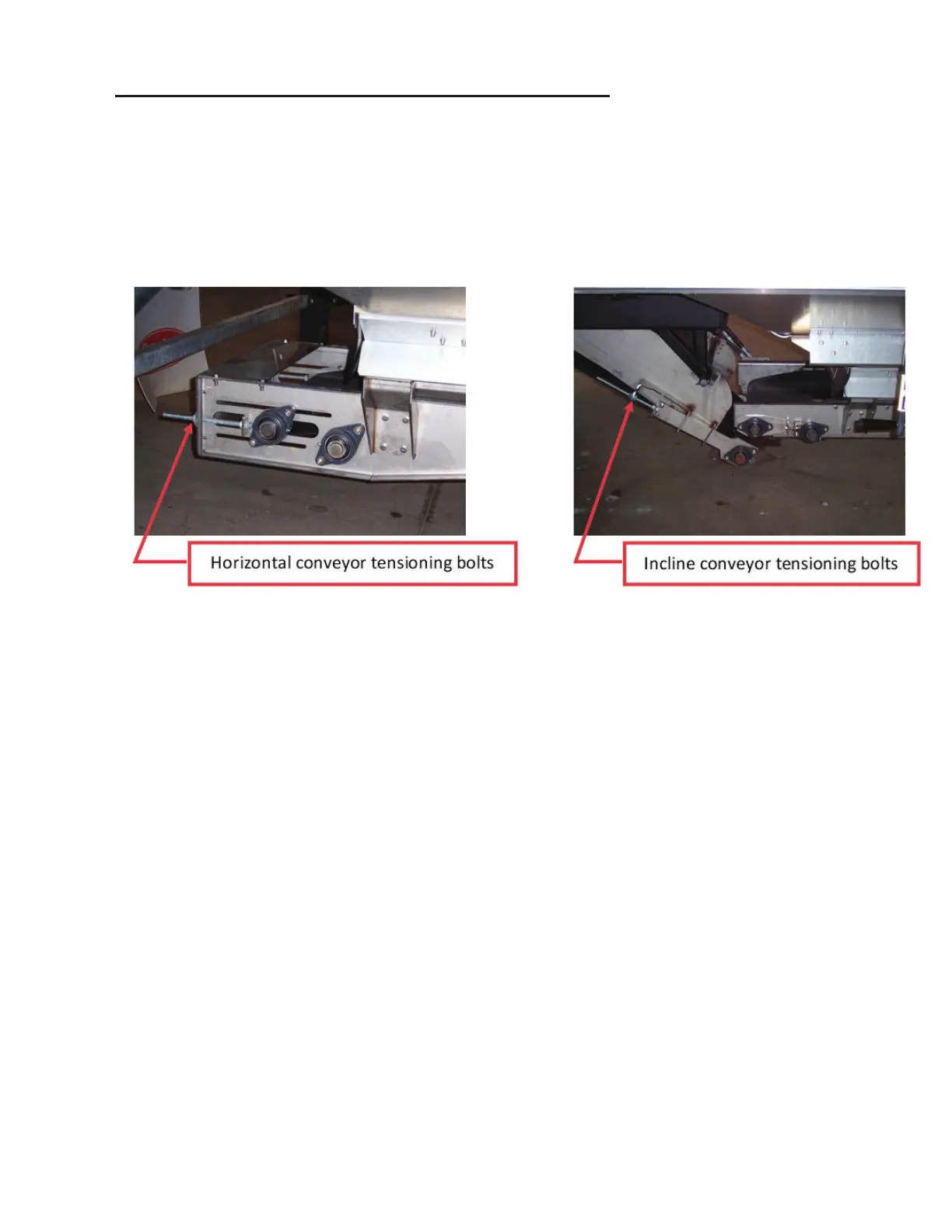

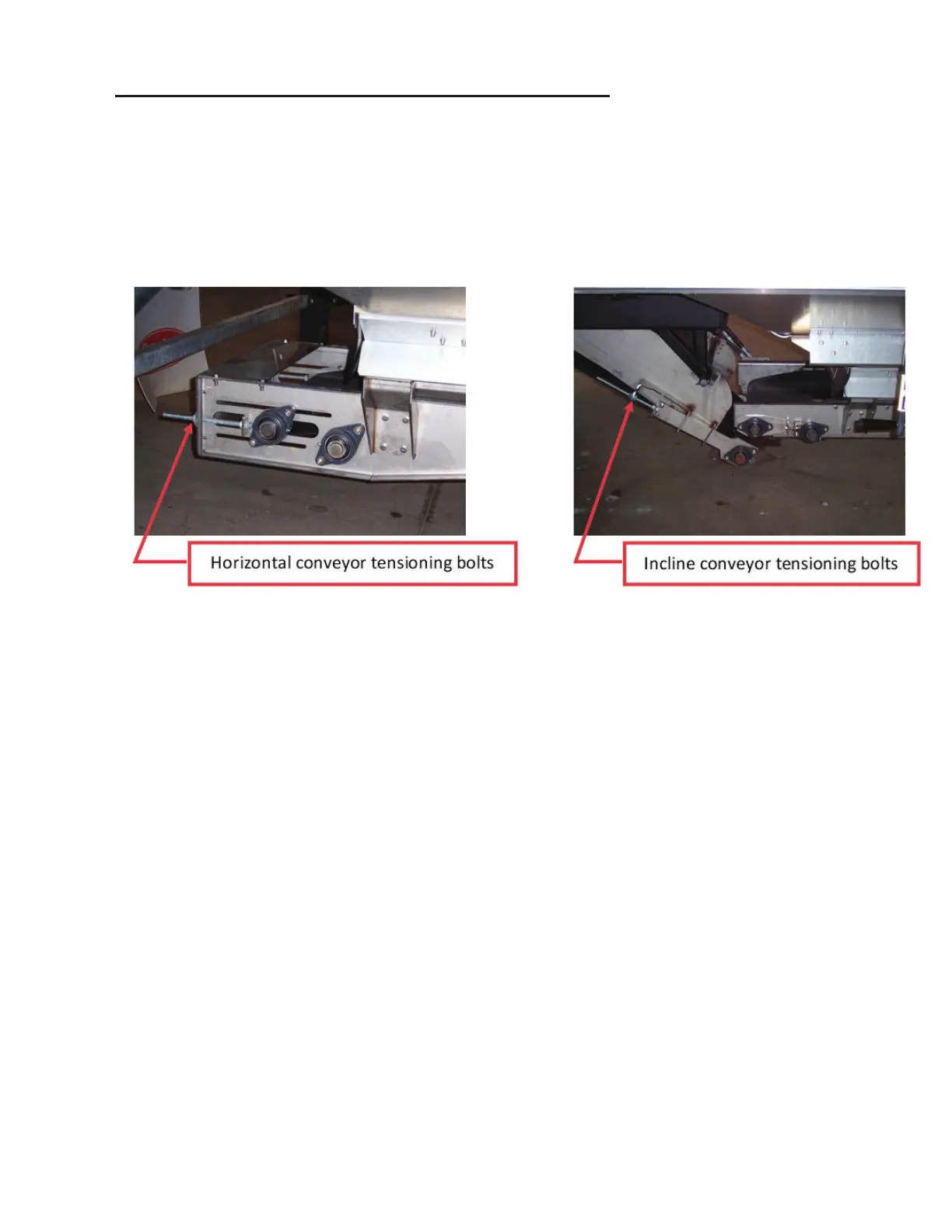

The belt is tensioned and tracked with the adjustment bolts as shown.

Tensioning the conveyor belt:

• Put marks on the un-tensioned belt exactly 100 inches apart.

• This has to be done on the left as well as the right side of the conveyor belt.

• Tension the belt and let it turn a few times to equally divide the belt tension over the belt.

• Then measure the elongation.

• The recommended elongation for conveyor belts is 1% - 3%.

• The marks should be 101 to 103 inches apart for the recommended elongation.

• Adjust the belt tension, if necessary, to achieve the 101” inches.

• Check the belt for slippage between the belt and the drive pulley. If the belt slips, put more tension

in the belt.

Loading...

Loading...