60

Date of Origin – 02/24/11

Updated – 02/03/20

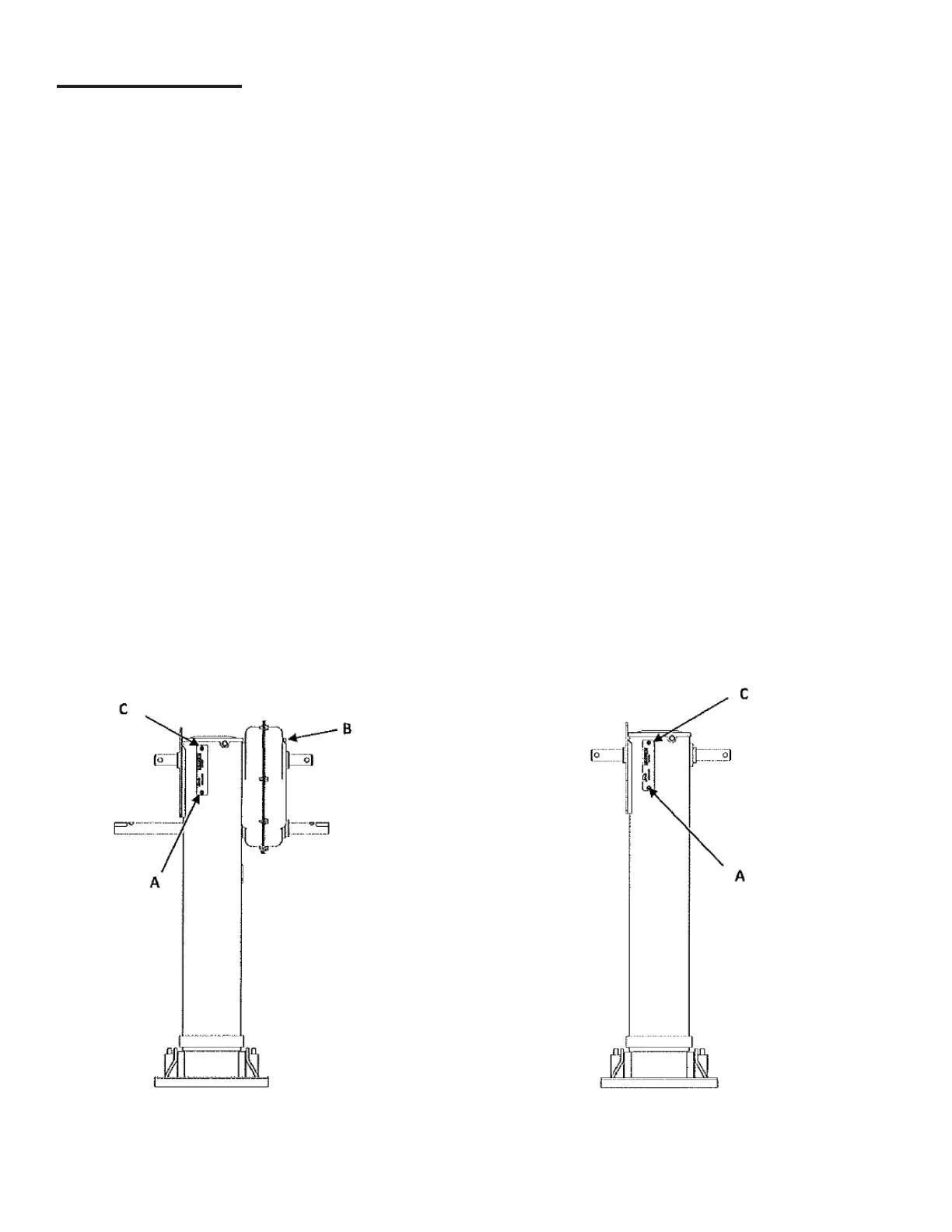

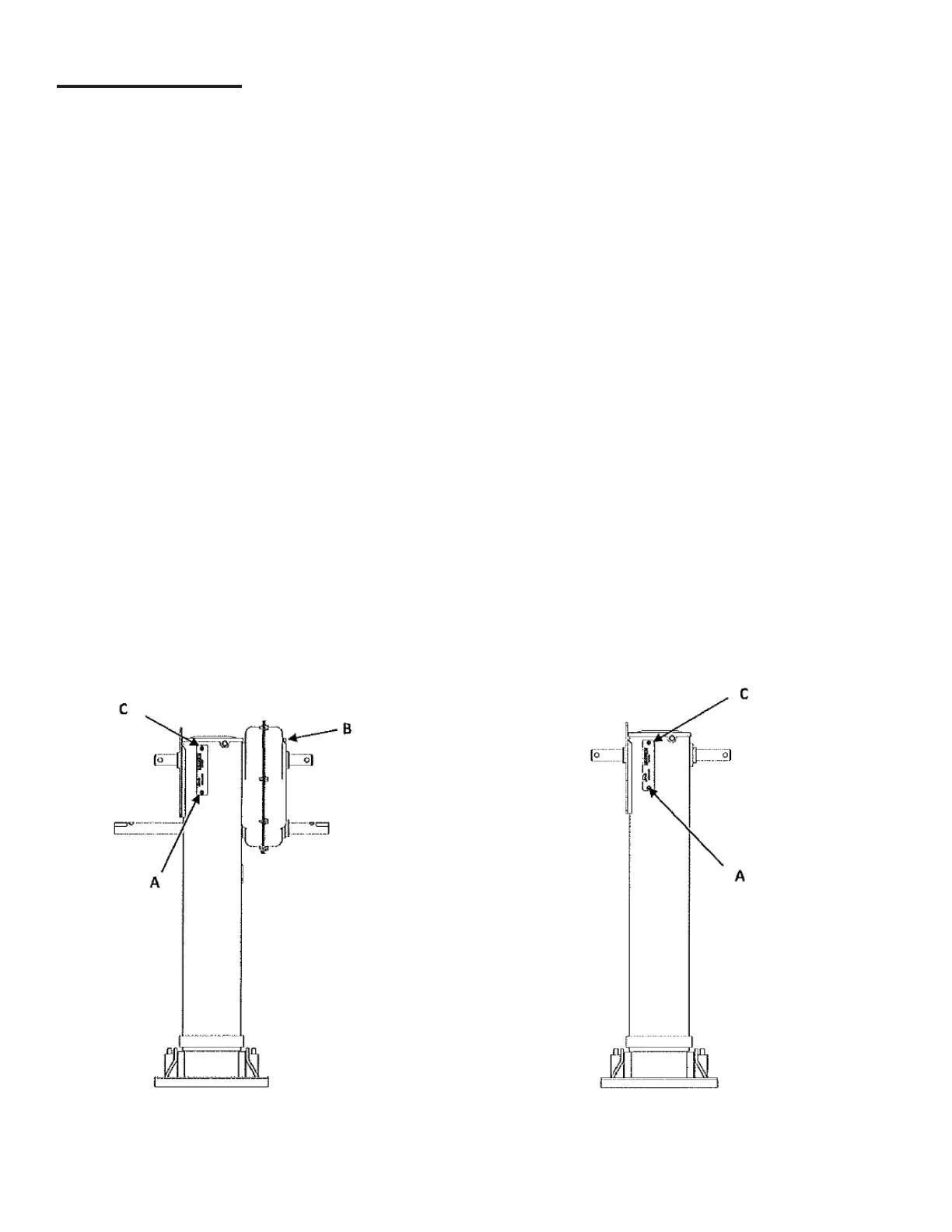

FIGURE 1

For moderate temperature operations (20° F to 150° F) use a lithium or an anhydrous calcium

extreme pressure grease.

Lubricate as follows: (see FIGURE 1)

1. Fully retract the landing gear, then using high gear, lower the leg 2-3 turns and lubricate the lift-screw assembly

through grease tting “A” (see landing gear legs shown below). Apply ½ lb. of grease. Distribute the lubrication by

extending and retracting the leg several times.

2. Lubricate the gearbox, using grease tting “B”. Apply ¼ lb. of grease

3. Lubricate the bevel gear using grease tting “C”.

Apply ¼ lb. of grease.

LANDING LEGS

LANDING GEAR LUBRICATION IS IMPORTANT!

Your landing gear was adequately greased and packed with high quality lubricants when manufactured and will not

require additional lubrication for the rst ve (5) year period of service and operation. Following the initial ve year

period, it will be necessary to periodically supplement this lubrication to maintain satisfactory performance for your

particular application. Re-lubrication should be part of your preventative maintenance program and should be done every

month or more often, if required.

For low temperature operations (under 20° F) use a lithium or an anhydrous calcium extreme pressure grease

that operates down to -65°F.

For cold weather operations, it is also recommended to ll the gearbox approximately 3/4 full with grease. This

helps minimize moisture accumulation, which can freeze, causing hard gear cranking.

Loading...

Loading...