45

Date of Origin – 02/24/11

Updated – 02/03/20

Grease lubricated wheel ends should be changed whenever seals are replaced, brakes are relined or at least every

12 months or 100,000 miles with NLGI Grade 1 or 2 grease.

To install semi-uid grease

1. Pack both bearings with grease by forcing grease into the cavities between rollers

and cage from the large end of the cone.

2. Apply a light coat of grease to the spindle bearing journals.

3. Install the inner bearing, inner seal and hub.

4. Fill the cavity between the bearing races with grease up to the smallest diameter of the

bearing cups.

5. Install the outer bearing and adjust end-play as noted in the “Wheel Bearing Adjustment

Procedure” section.

6. Apply a light coat of grease to the interior of the hubcap and wheel retention hardware

to indicate what lubricant is installed as well as to help prevent corrosion of these parts.

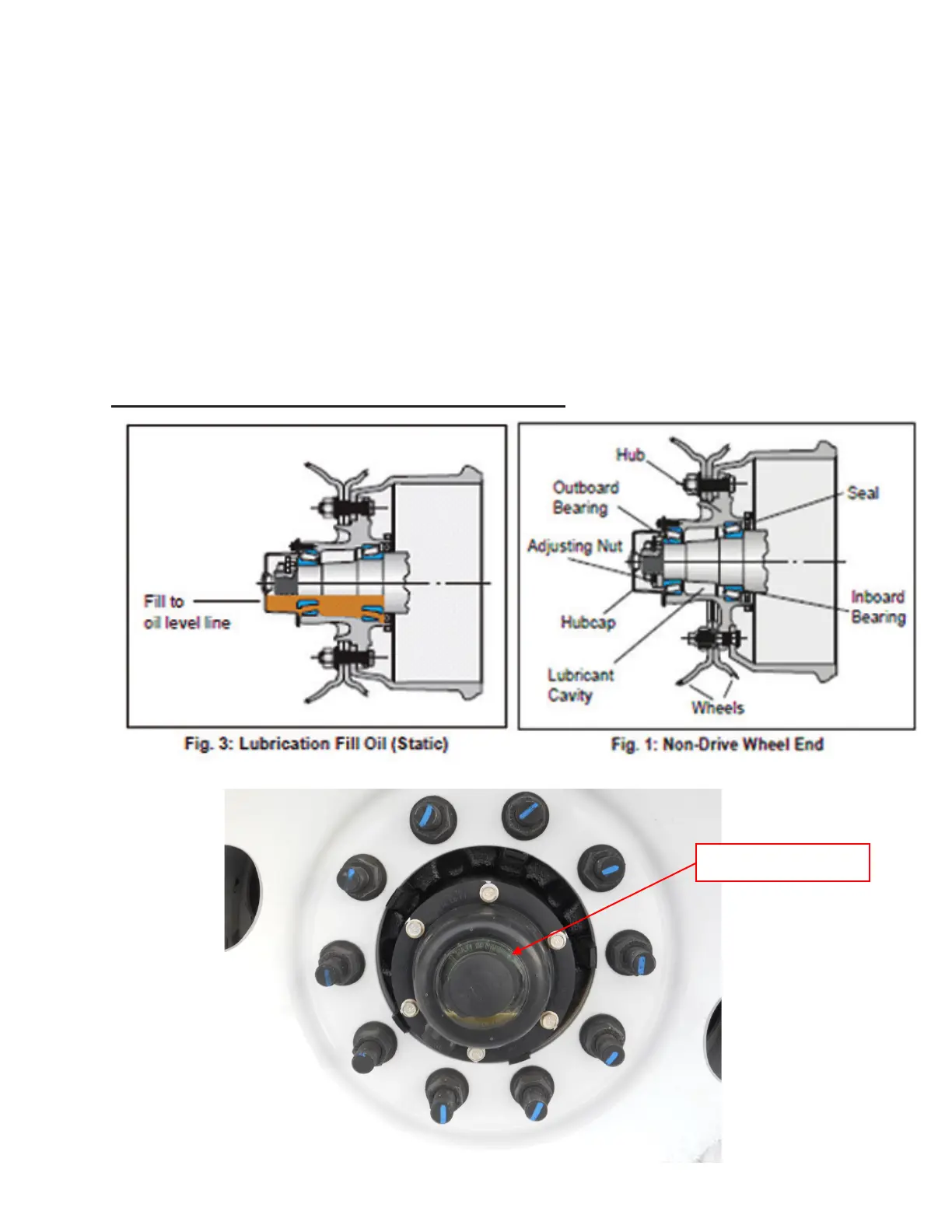

HUB/BEARING LUBRICATION OIL REQUIREMENT

Loading...

Loading...