6

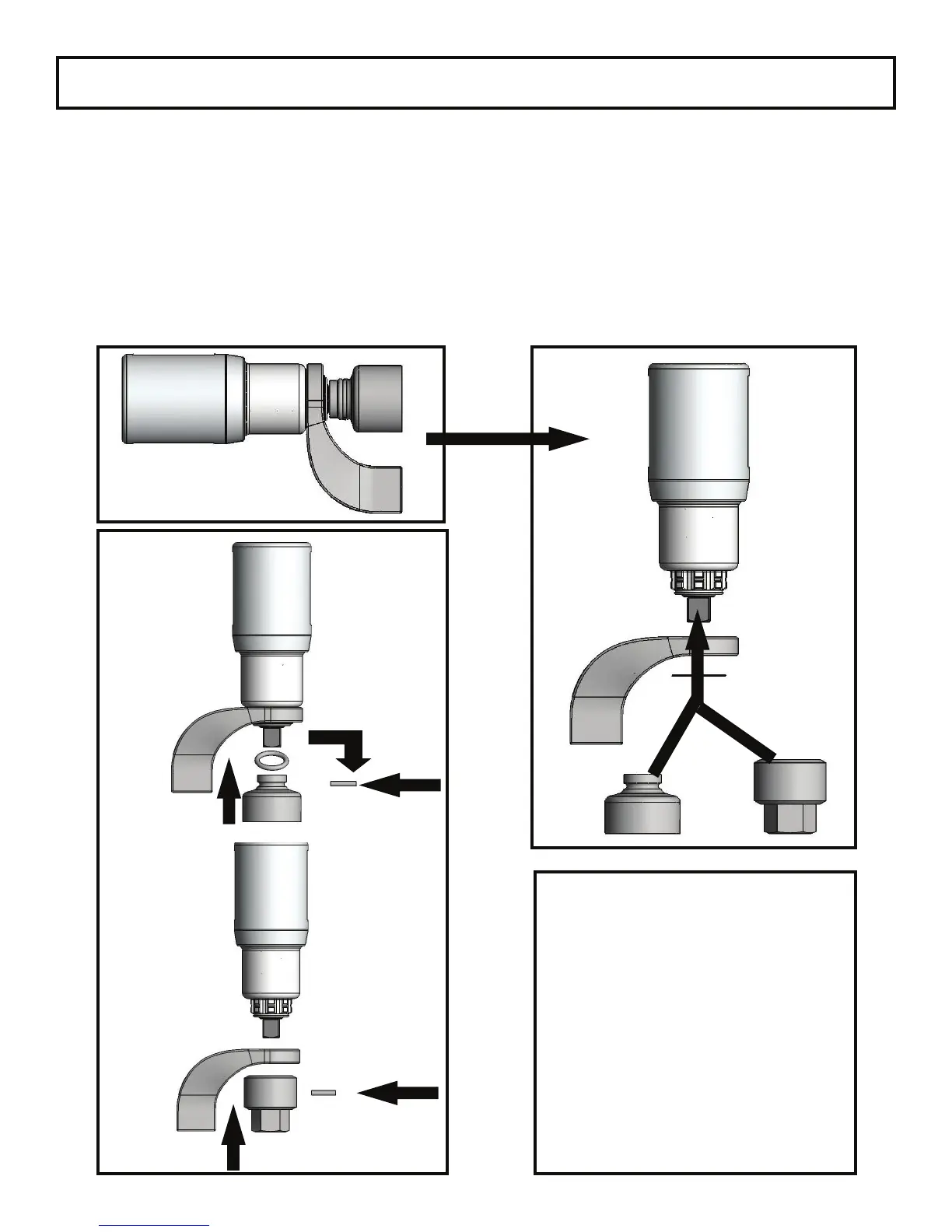

1. Ensure the air line is not connected to the tool before performing the following steps.

2. Ensure the reaction arm is properly attached and secured to the splined section of the torque tool.

3. Select your desired square drive size and bolt/nut AF size impact socket or hex-drive socket for use.

4. Secure impact socket onto the tool square drive with a safety pin and secure a safety o-ring on the

socket.

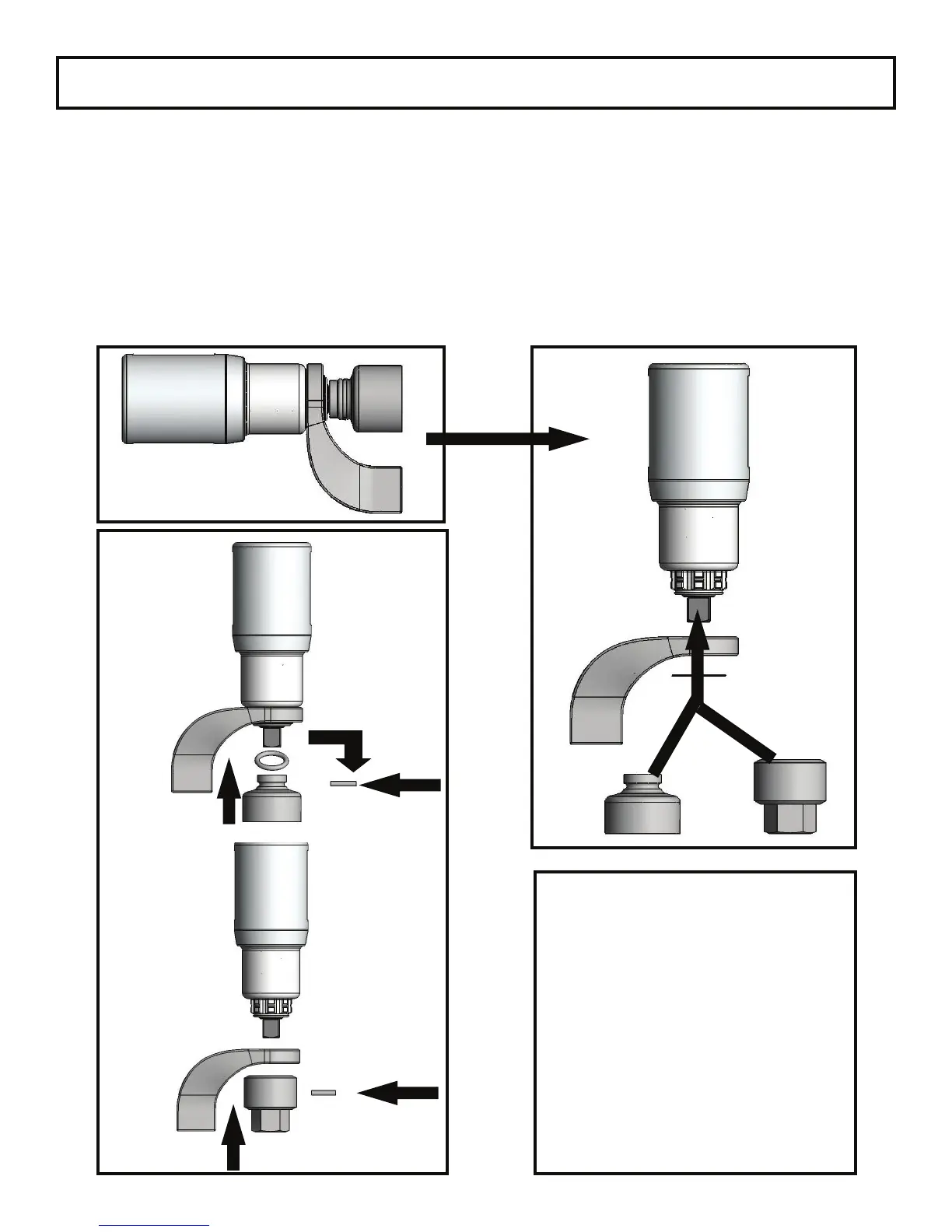

5. Use a quality Filter/Lubricator/Regulator Unit that meets airow requirements or use a TorcUP

RAPTOR F/R/L Unit.

6. Ensure F/R/L has proper pneumatic oil for lubrication. See the requirements for oil specications

sheet.

7. See illustration below for details:

IMPORTANT

For long life of the air motor:

Use a quality F/R/L Unit

Must meet airow requirements

Lubricator provides oil to air motor

Filter separates water to extend life

to motor vanes

Regulator allows accurate

setting of output

1.

1.

1.

2.

2.

2.

3.

Slide Rubber Safety Ring

Over Safety Pin

Safety Pin

Safety Screw

PLACING THE TOOL IN SERVICE

Loading...

Loading...