CAL Optional Design

- 8-

The gland should be slightly recessed from the casing cover. The

gland packing should be lightly tightened at the beginning. Then,

re-tighten it after running the pump for a certain period. Adjust the

gland packing so that liquid leakage from the gland is approx. 10 to

20 cc/min.

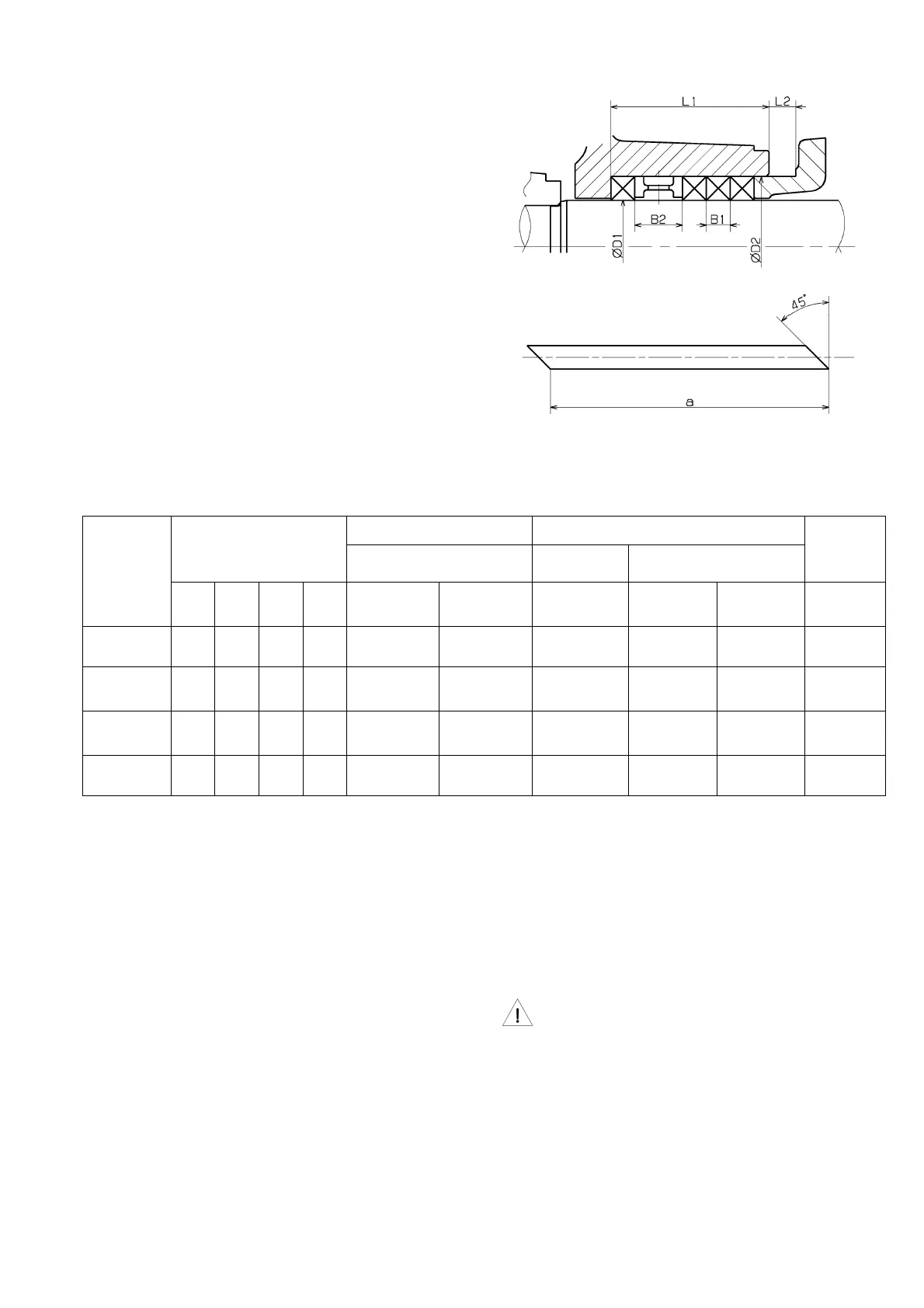

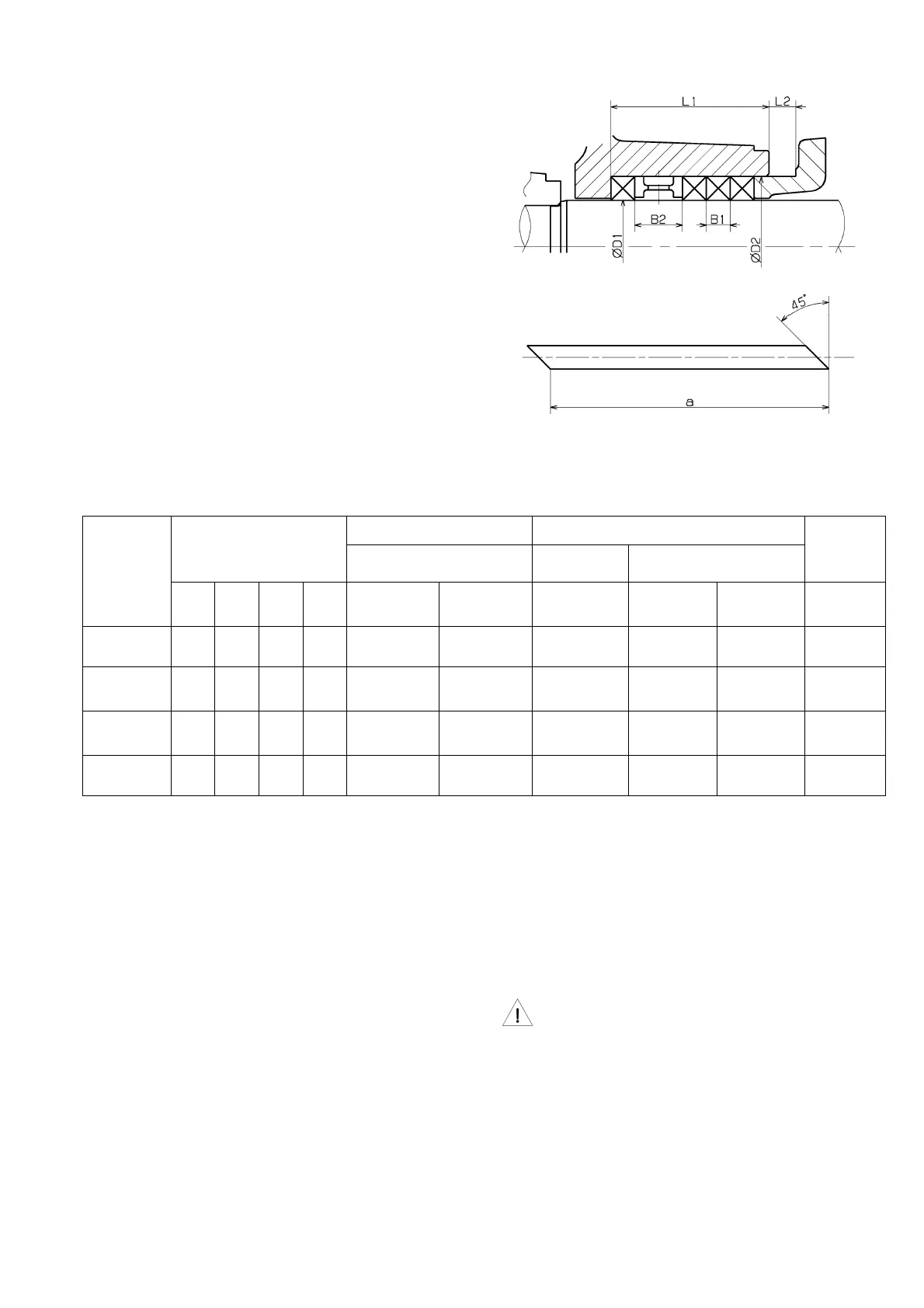

The dimension of the shaft seal and gland packing are shown in Fig

3.2-2 and Table 3-1.

Fig 3.2-2

Table 3-1 the dimension of the shaft seal and gland packing

Unit: mm

Shaft size

Shaft seal dimensions

Quantity of gland packing Gland packing dimensions

Lantern

ring

dimensions

Lantern ring Molded part String-shaped part

D1 D2 D3 D4 Provided None D1×D2×B1 Thickness

Overall

length (a)

B2

25-360 24 40 53 9 4 6 24×40× 8 8 100.5 16

35-470

45-470

32 48 53 9 4 6 32×48× 8 8 125.7 16

45-470A

55-530

45 65 65 12 4 6 45×65×10 10 172.8 20

65-530 55 75 65 12 4 6 55×75×10 10 204.2 20

Use molded ring-shaped gland packing as much as possible.

3.3. Meters and gauge

It is recommended that a pressure gauge or compound pressure

gauge should be mounted to the pump body or the suction piping in

proximity to the pump, and that a pressure gauge should be

mounted to the discharge piping. These pressure gauges must be

provided with gradations capable of covering about 150% of

maximum operating pressure. Also connect a gauge cock to each

gauge. When pumping a corrosive liquid, use an anti-corrosion

gauge cock. When pumping liquid contains free matter or solid

matter, use a proper strainer with the gauge cock. For the long life

of each gauge, keep the gauge cock closed all the times, expect

when it is opened to read the operating pressure.

3.4. Bearings

Maintenance and inspection of the pump bearings are very

important. Maintenance and control of bearings of each lubrication

type are described below.

3.4.1. In the case of grease lubricated bearings

Inspection and control of the bearing temperature and replacement

of the ball bearings (3210) are required at an appropriate timing.

Heat-resistant grease is sealed in the bearing. The

maximum permissible temperature thereof is 90

degrees C max on the bearing housing (3300) surface

or ambient temperature plus 55 degrees C max.

The bearing replacement intervals vary depending on operating

conditions. During continuous operation, the bearings must be

replaced at an interval of approx. 9000 hours, as standard. In the

case of short-time operation, it is recommended that the bearings

should be replaced every two years. Further, it is recommended to

Loading...

Loading...