CAL Optional Design

- 13-

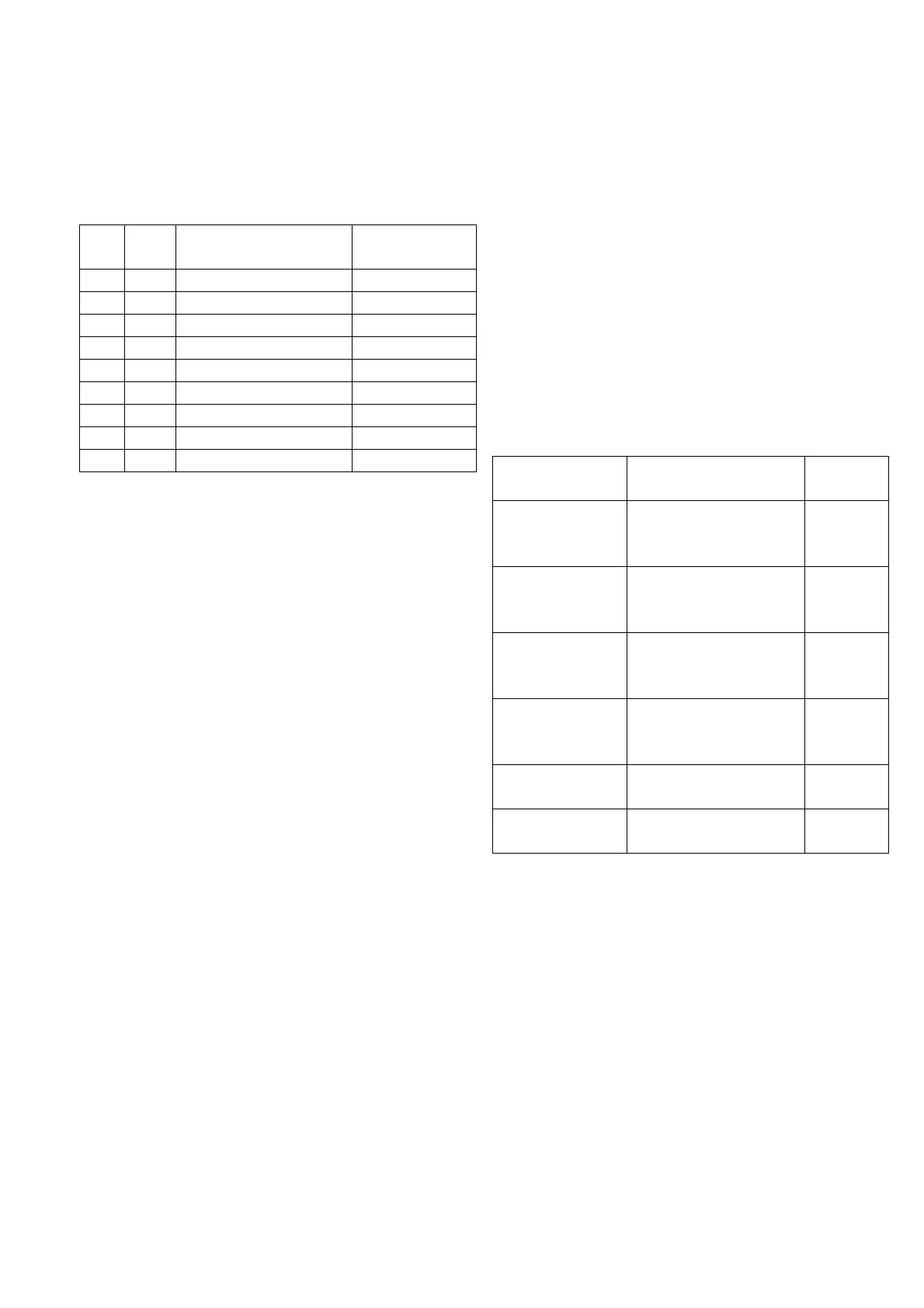

4.4.2. Recommended spare parts

As shown in Table 4-1.

Table 4-1 Recommended Spare Parts and

Replacement Cycle

Item

No.

Parts

No.

Parts name

Replacement

cycle (year)

1 2100 Shaft

*1

6 (9,000 hours or 2)

2 3210 Ball bearing

*1

9,000 hours or 2

3 4000 Flat gasket 2

*3

4 4120 O-ring 2

*3

5 4330 Mechanical seal 2

*3

6 4610 Gland packing 1

*3

7 5020 Casing wearing ring 6

8 5500 Washer (for Hard lock nut) 2

*3

9 9233 Hard lock nut 2

*3

*1 It is recommended to replace the bearings together with the

shaft for reduction of working manhour and improvement of

replacement work quality at customer side.

*2 Figure in parenthesis shows the replacement cycle in the case

of replacing the bearings together.

*3 When disassembling, replace them with new parts.

5. Mechanical seal

5.1. General

(1) The life of mechanical seal is remarkably shortened by

inclusion of foreign matter therein.

In reassembling the pump, clean the mechanical seal and

other internal components. In addition, be careful not to

permit such foreign matters to intrude in the pipeline during

running.

(2) Absolutely avoid dry running of the pump. (Including the

running under the seal box pressure below the atmospheric

bar.) Dry running will result in seizure trouble of the

mechanical seal, eventually causing not only the

mechanical seal but also the pump itself to be damaged.

(3) The sliding surfaces of the mechanical seal are fine finished

by lapping. Be careful to protect it from flawing and

chipping in handling.

(4) In principle, the sliding surface of the mechanical seal after

overhaul must be replaced with a new one, or must be

re-finished by lapping.

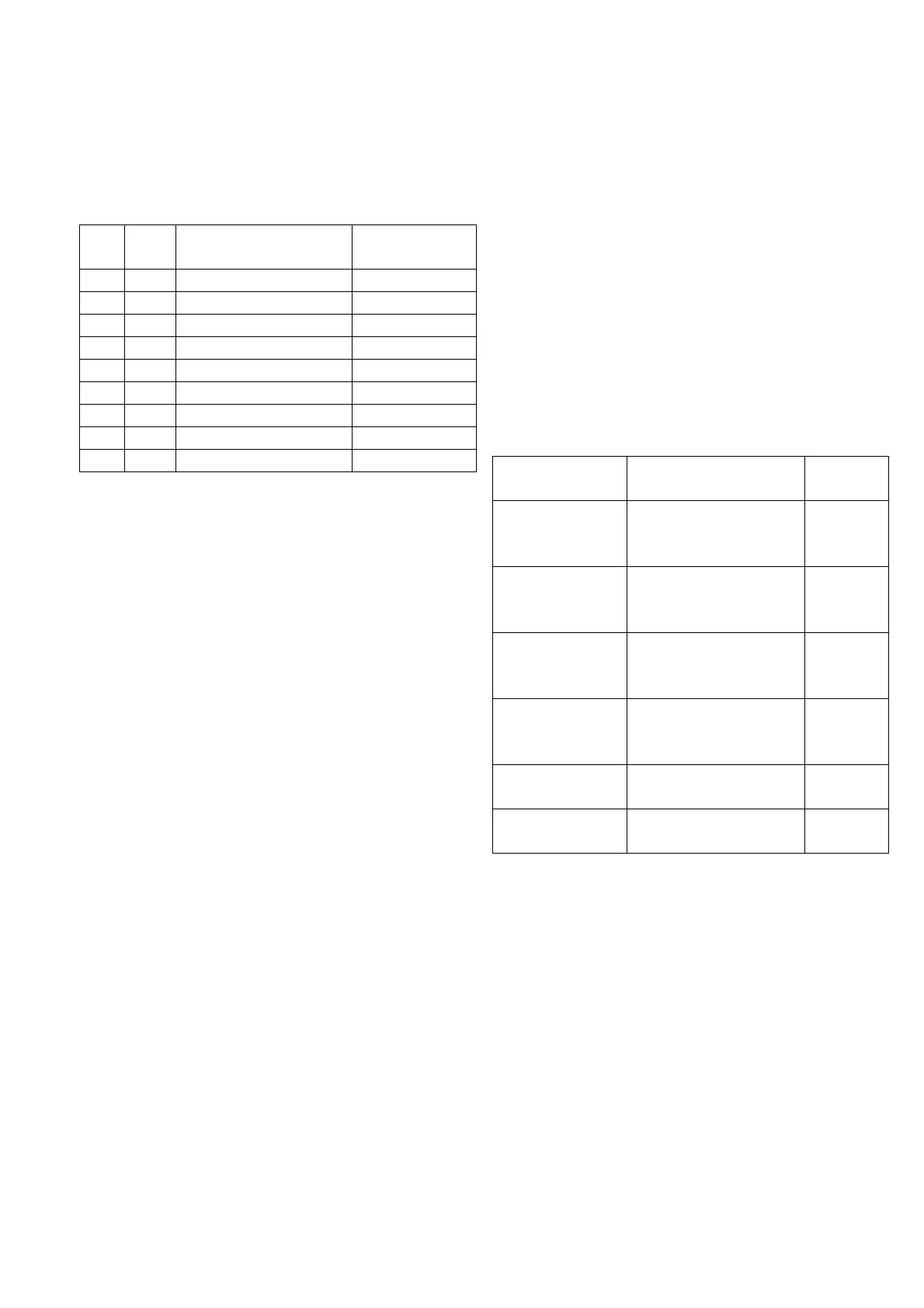

5.2. Outline of Construction Parts

For the mechanical seal sectional drawings, refer to Table 5-1.

The material of mechanical seal is different depending on use

conditions. Refer to the sectional drawing of pump.

Table 5-1 Mechanical Seal Type

Mechanical seal

type

Remark

Sectional

drawing

CA φd SS

Rubber bellows type single

mono-coil seal

(simple type)

Fig 5.2-1

LCA φd F

LCA φd E

Rubber bellows type single

mono-coil seal

(clutch type)

Fig 5.2-2

LTW φd F

LTW φd E

Rubber bellows type double

mono-coil seal

(clutch type)

Fig 5.2-3

LA200-RFφd

LA200-REφd

LA200-RKφd

Multi-spring type single seal

(SiC × carbon)

Fig 5.2-4

L9SA-SEφd

L9SA-SKφd

Multi-spring type single seal

(SiC × SiC)

Fig 5.2-5

MBS100-RFφd

Metal bellows type single

seal

Fig 5.2-6

MBS100-RFφD is balanced seal. Other models are unbalanced

seal.

Loading...

Loading...