CAL Optional Design

- 22-

7. Troubleshooting

Main possible troubles of the pump are as described hereunder. If a trouble occurs with the pump, stop the pump immediately, and take

corrective actions depending on the cause and phenomenon of the trouble. If the trouble can not be fixed or the cause can not be identified in

spite of having implemented the following measures, examine the content of the trouble in detail. After that, contact a nearest distributor or

dealer authorized by Torishima.

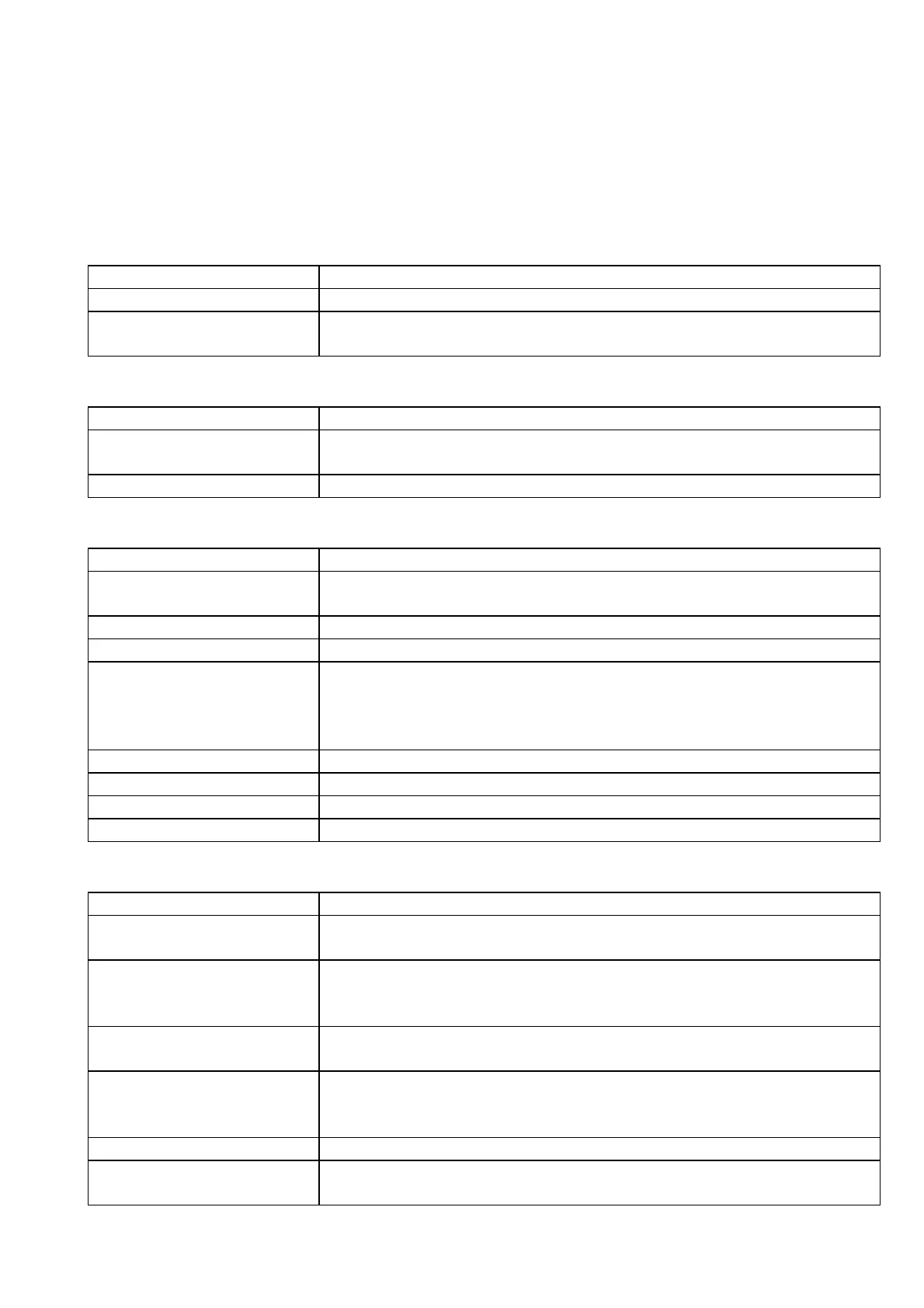

7.1. Pump cannot be filled with liquid.

Probable Cause Corrective Action

Air intake from discharge valve Tighten the discharge valve. If the problem persists, check the seat surface, and re-adjust the full-close limit.

Fault of air bleeding solenoid valve Provide a bypass, or open the valve manually, if a manual handle is provided.

Check and repair the valve, as required.

7.2. Pump cannot start.

Probable Cause Corrective Action

Starting conditions cannot be satisfied. Check the starting conditions. If this problem is caused by a fault of equipment or circuit, repair the relevant

part.

Protective circuit is activated. Check if the pump has been reset after recovery from a fault.

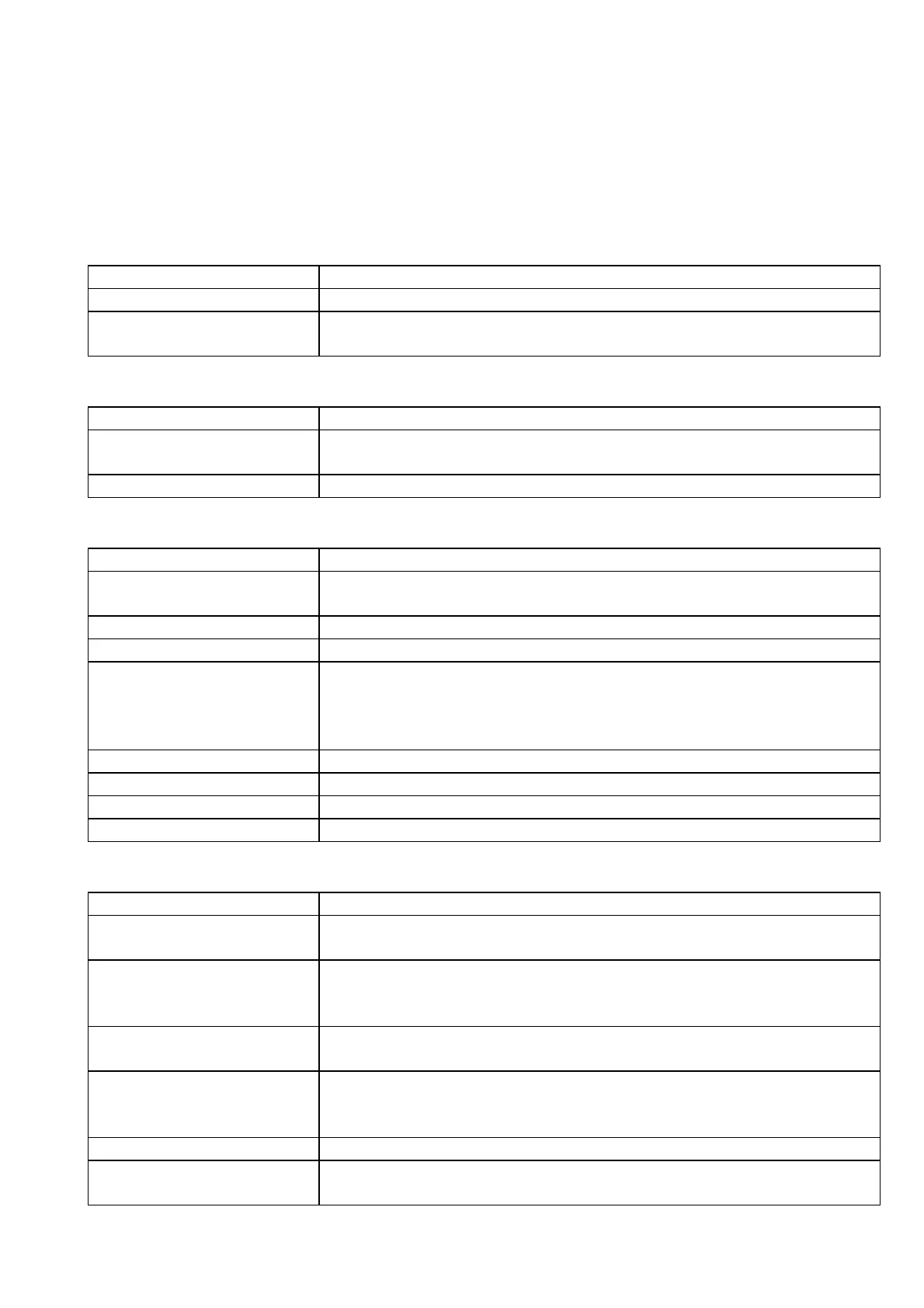

7.3. Insufficient discharge or incapable of pumping

Probable Cause Corrective Action

Insufficient priming of pump and piping,

or insufficient air bleeding

Execute priming or air bleeding again. If the problem persists, repair the piping, and re-design the air

bleeding valve and the air bleeding pipe.

Clogged suction valve or impeller Clean piping or remove and clean impeller as necessary.

Excessive wear of pump parts Disassemble pump and repair or replace faulty parts or adjust clearance between sliding parts as necessary.

Ingestion of air from stuffing box Increase the sealing water pressure, and check if sealing water normally flows. Clean inside of the sealing

water piping, if necessary.

If the self flushing pressure is insufficient, change the flushing method to external flushing from an external

high-pressure source.

Low rotation speed Check the motor for overload or abnormal voltage to keep the motor load and voltage normal.

Reversing Exchange connection of motor terminals.

Cavitation Check for clogging of a foreign object in the suction valve, suction strainer and piping, and remove it, if any.

Excessive total head required The actual pump head is higher than the planned level. Consult us for corrective action.

7.4. Motor overload

Probable Cause Corrective Action

The motor load is remarkably deviated

from the rating.

Narrow the discharge valve opening to adjust the flow rate appropriately.

Liquid of large weight per volume or high

viscosity

If the specific gravity and viscosity given in the specifications cannot be maintained, reduce the discharge

rate to an allowable lower level. If it is not effective, adjust the outer diameter of the impeller, or use a motor

with larger capacity.

Check valve with automatic discharge

valve does not work well.

Replace worn parts of valve.

Excessively high rotation speed Restore the rotation speed to the specified value by adjusting the power supply voltage, or by using the

governor. If the rotation speed cannot be restored, reduce the discharge rate to an allowable lower level. If it

is not effective, adjust the outer diameter of the impeller, or use a motor with larger capacity.

Foreign object trapped in pump Disassemble and remove foreign objects.

Freezing of pumped liquid To leave the pump unused in cold weather, be sure to drain liquid from the pump so that no liquid remains in

the pump.

Loading...

Loading...