CAL Optional Design

- 4-

0.4.1. Volute casing

Back pull out type volute casing (1020) is fixed with the casing

cover (1610) and bearing housing (3300) at the driver side by

means of bolts. The flat gasket (4000.3) is inserted between the

mating surface of the volute casing (1020) and the casing cover

(1610) to seal the pumped liquid.

The following models provide double volute casing structure to

reduce radial thrust.

125-400, 200-250, 150-315, 150-400

0.4.2. Impeller

The impeller (2300) is installed with balance hole to balance the

greater part of axial thrust. Sliding clearance between the casing

wearing ring (5020) and the impeller is held to the minimum so that

pumped liquid at discharge side will not return to suction side.

The impeller is inserted through the shaft (2100), and fixed to shaft

(2100) with Hard Lock Nut® (9233). These Hard Lock Nut®

consist of two pieces of bottom nut (convex type) and upper nut

(concave type), special nuts having looseness preventive function.

0.4.3. Shaft seal

Casing cover (1610) as a part of the shaft seal is jointed, together

with bearing housing (3300), to volute casing (1020).

The shaft seal is available in two types; the mechanical seal type

and the gland packing type.

(1) In the case of mechanical seal type.

For the shaft seal construction, refer to Section 5 (P.13).

(2) In the case of gland packing type.

For the shaft seal construction, refer to Section 6 (P.21).

0.4.4. Bearing

The pump shaft (2100) is supported with two ball bearings (3210).

The ball bearings are fit on the shaft, which are placed in the

bearing housing (3300).

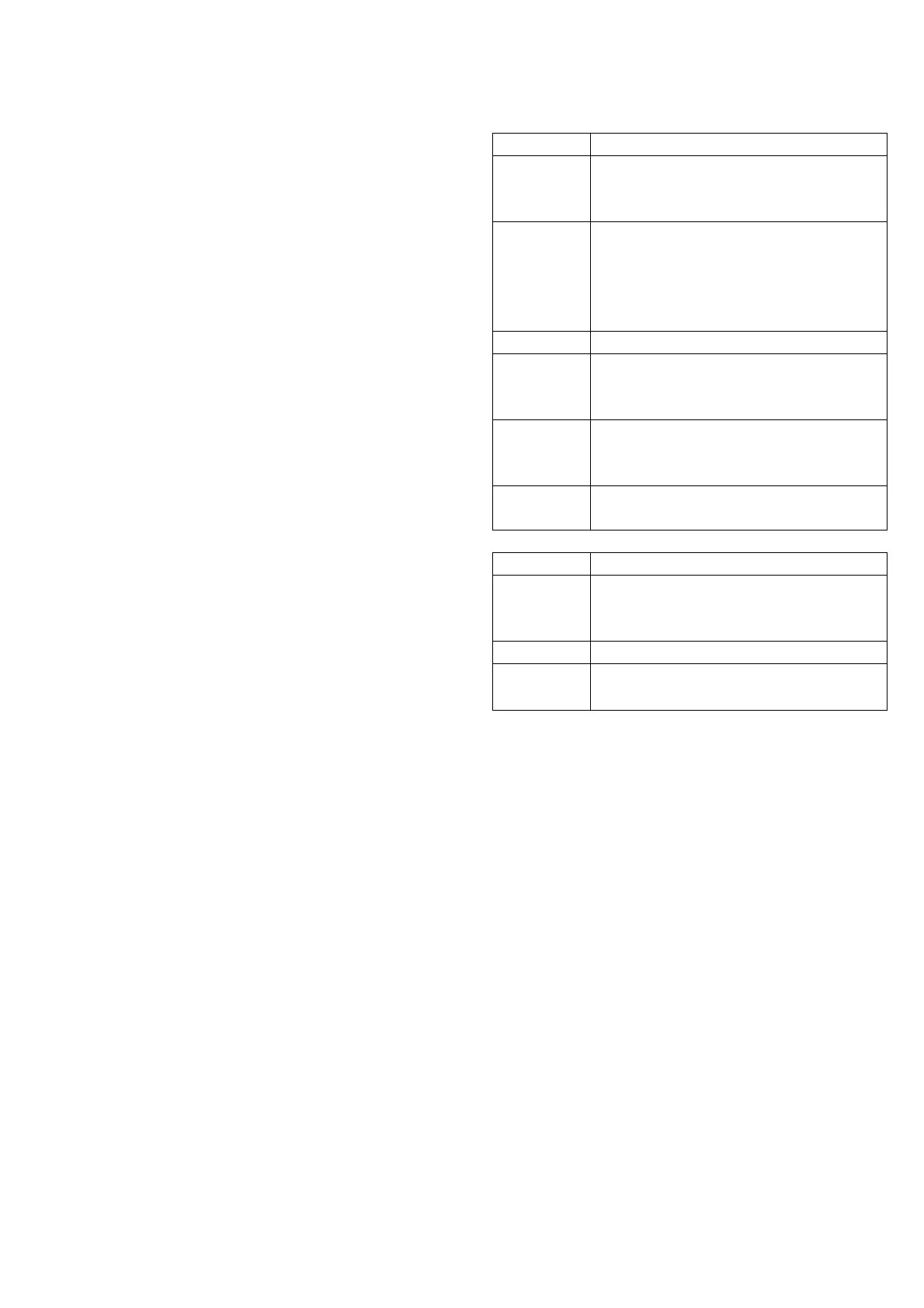

0.4.5. Shaft

The shaft components of each pump type are interchangeable with

those of other pump. As shown in Table 0-2, the shaft is available

in six sizes, which cover all models of the CAL pumps.

Table 0-2 Combination of pump size and shaft size

[The case of 4 pole motor drive]

Shaft size Pump size

25-360 32-125 40-125 65-125

32-160 40-160 50-160 65-150

32-200 40-200 50-200 65-190

35-470 80-150

80-190 80-200 100-190

32-250 40-250 50-250 65-240

80-240 100-245 80-250

65-310 80-310 100-310

45-470 50-315

45-470A 150-200

125-250

80-400

55-530 200-250

125-315

100-400 125-400

65-530 150-315

150-400

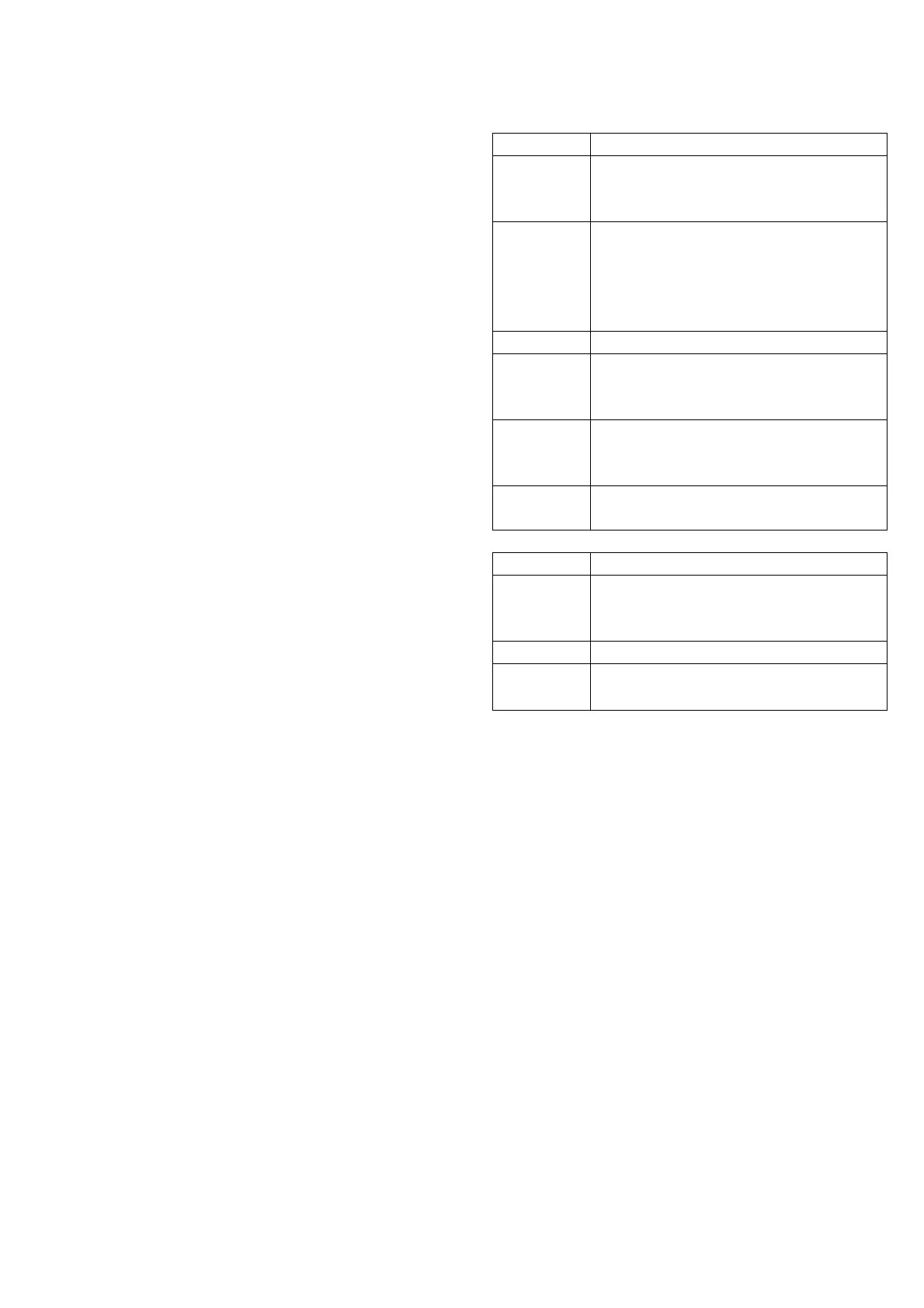

[The case of 2 pole motor drive]

Shaft size Pump size

25-360 32-125 40-125 65-125

32-160 40-160 50-160

32-200 40-200 50-200

35-470 80-160

45-470 80-200

32-250 40-250 50-250 80-250

1. Installation

1.1. Installation of base plate

Perform installation and centering of the pump by skilled workers.

Incorrect installation and centering will cause various troubles

while the pump is in running.

When the pump and the motor are directly coupled on a common

base plate, the pump has been correctly centered before shipment.

However, when installing the base plate at a local site, follow the

sequence below and, after installation, check that it is leveled as

specified.

(1) Prepare packers and several kinds of 1mm to 0.1mm thick

shims for leveling adjustment use, prior to installing.

(2) After complete setting of the foundation concrete, position

each packer at both sides from each foundation bolt and at

the portions equivalent to both side from each of the pump

and motor support feet. After positioning, place a mortar

onto the foundation floor (under the base plate) in each

packer position and the place each packer on the motor. In

Loading...

Loading...