Note:Adjusting1sideofthecuttingunitaffects

theotherside,the2clickswillprovideclearance

forwhentheothersideisadjusted.

Note:Ifstartingwithalargegap,bothsides

shouldinitiallybedrawncloserbyalternately

tighteningtherightandleftsides.

7.Slowlyrotatethereelsothatthesameblade

thatyoucheckedontherightsideiscrossing

thebedknifeapproximately25mm(1inch)in

fromtheendofthebedknifeontheleftsideof

thecuttingunit.

8.Turntheleftbedbaradjusterclockwiseuntilthe

shimcanbeslidthroughthereeltobedknife

gapwithlightdrag.

9.Returntotherightsideandadjustasnecessary

togetlightdragontheshimbetweenthesame

bladeandbedknife.

10.Repeatsteps8and9untiltheshimcanbeslid

throughbothgapswithslightdrag,but1clickin

onbothsidespreventstheshimfrompassing

throughonbothsides.

Note:Thebedknifeisnowparalleltothereel.

Note:Thisprocedureshouldnotbeneeded

ondailyadjustments,butshouldbedoneafter

grindingordisassembly.

11.Fromthisposition(i.e.,1clickinandshimnot

passingthrough)turnthebedbaradjusters

clockwise1clickeach.

Note:Eachclickturnedmovesthebedknife

0.022mm(0.0009inch).Donotovertighten

theadjustingscrews.

12.T estthecuttingperformance;refertoChecking

theCuttingUnit(page8).

AdjustingtheRearRoller

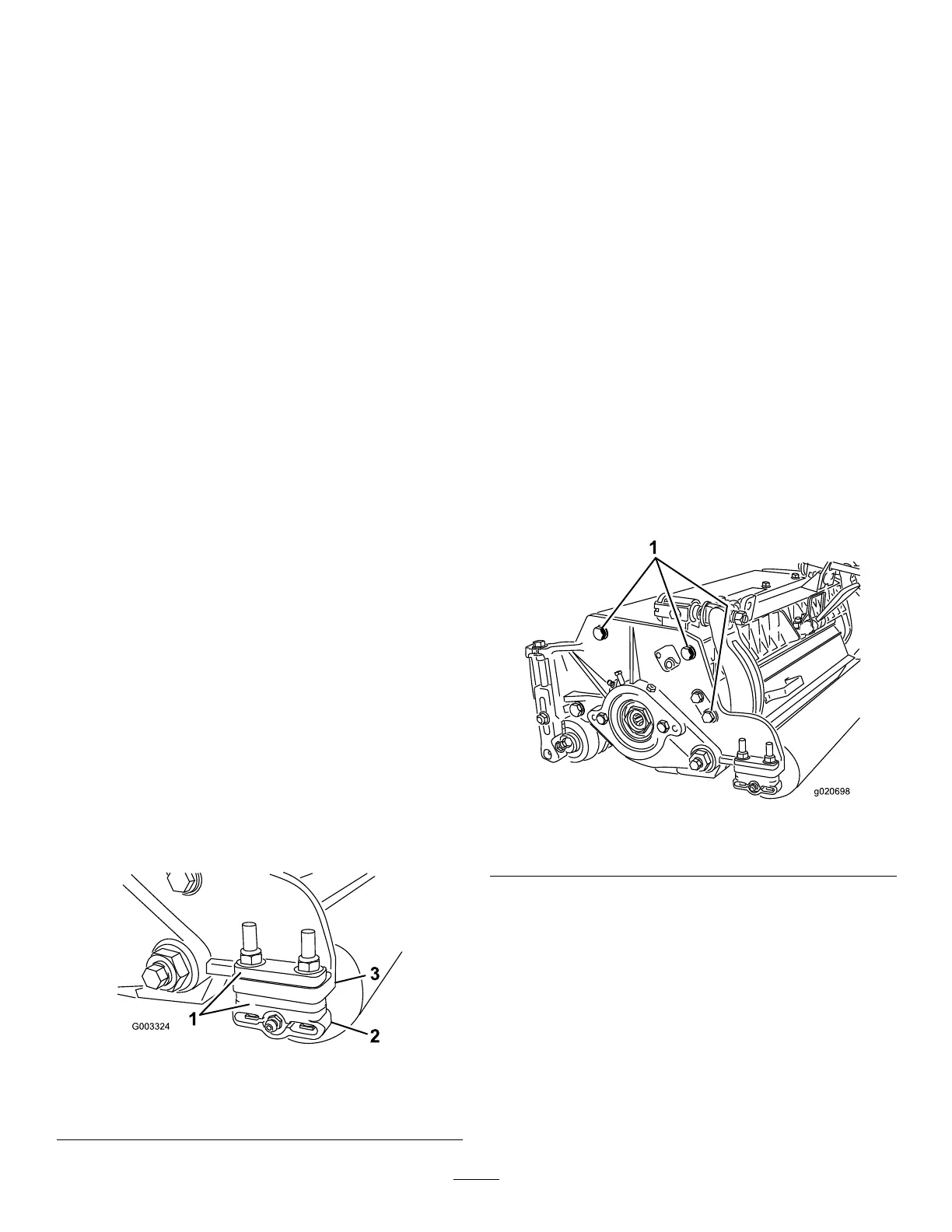

1.Adjusttherearrollerbrackets(Figure11)tothe

desiredheight-of-cutrangebypositioningthe

requiredamountofspacersbelowtheside-plate

mountingange(Figure11)pertheHOCChart.

g003324

Figure11

1.Spacer3.Side-platemountingange

2.Rollerbracket

2.Raisetherearofthecuttingunitandplacea

blockunderthebedknife.

3.Removethe2nutssecuringeachrollerbracket

andspacertoeachside-platemountingange.

4.Lowertherollerandscrewsfromtheside-plate

mountingangesandspacers.

5.Placethespacersontothescrewsontheroller

brackets.

6.Securetherollerbracketandspacersto

undersideofsideplatemountingangeswith

thenutspreviouslyremoved.

7.Verifythatthebedknife-to-reelcontactiscorrect.

Tipthemowertoexposethefrontandrear

rollersandbedknife.

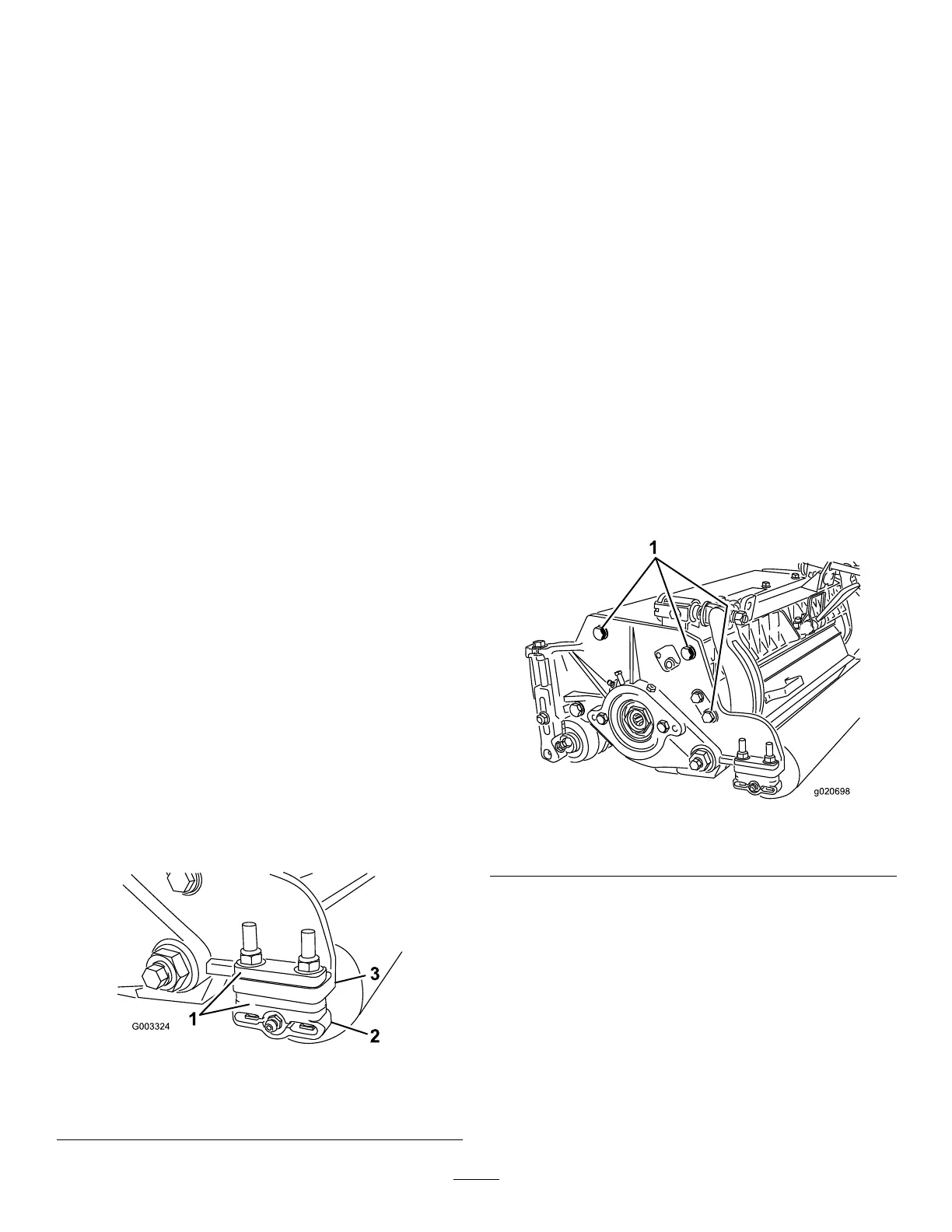

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponents;therefore,parallelingis

notrequired.Alimitedamountofadjustmentis

possiblebysettingthecuttingunitonasurface

plateandlooseningtheside-platemountingcap

screws(Figure12).Adjustandtightenthecap

screws.T orquethecapscrewsto37to45N·m

(27to33ft-lb).

g020698

Figure12

1.Side-platemountingcapscrews

10

Loading...

Loading...