CheckingtheHydraulicLines

andHoses

ServiceInterval:Every2years

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.

AdjustingtheCounterbalance

Pressure

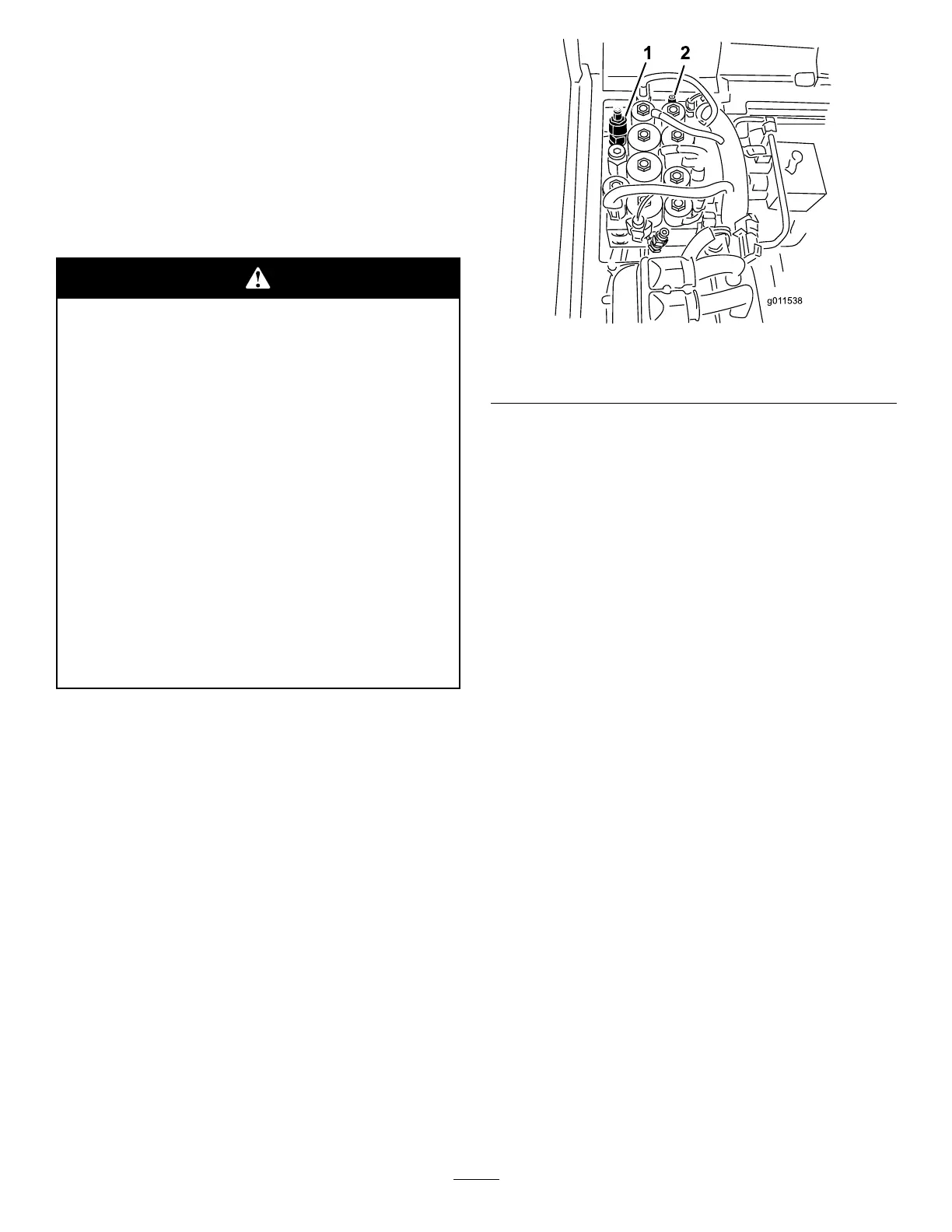

Thecounterbalancetestport(Figure76)isused

totestthepressureinthecounterbalancecircuit.

Recommendedcounterbalancepressureis470psi(3241

kPa).Toadjustthecounterbalancepressure,loosenthe

locknut,rotatetheadjustingscrew(Figure76)clockwise

toincreasethepressureorcounterclockwisetodecrease

thepressureandtightenthelocknut

Note:Allthreesidecuttingunitscastorwheelsshould

remainonthegroundwithcounterbalanceapplied.

Figure76

1.Counterbalanceadjusting

screw

2.Counterbalancetestport

50

Loading...

Loading...