InspectingandSharpening

theCutting-UnitBlade(s)

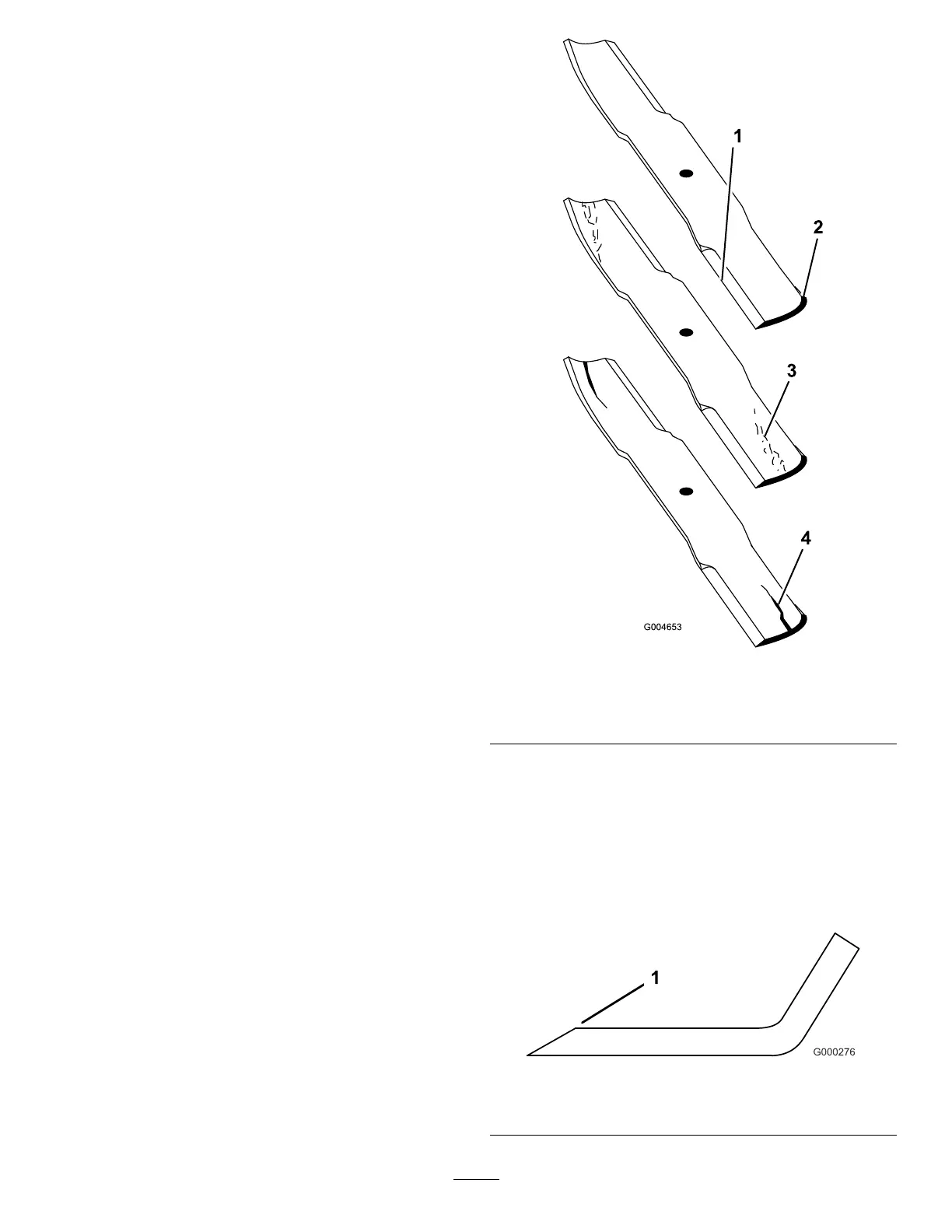

Boththecuttingedgesandthesail,whichisthe

turned-upportionoppositeofthecuttingedge,

contributetoagoodqualityofcut.Thesaillifts

thegrassupstraight,therebyproducinganeven

cut.However,thesailgraduallywearsdownduring

operation,loweringthequalityofcuteventhoughthe

cuttingedgesaresharp.Thecuttingedgeoftheblade

mustbesharpsothatthegrassiscutratherthantorn.

Adullcuttingedgeleavesthetipsofthegrassbrown

andshredded.Sharpenthecuttingedgestocorrect

thiscondition.

1.Parkthemachineonalevelsurface,raisethe

cuttingunits,engagetheparkingbrake,putthe

tractionpedalinNEUTRAL,putthePTOlever

intheOFFposition,shutofftheengine,and

removethekey.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsofthe

blademeet(Figure85).

Note:Becausesandandabrasivematerial

canwearawaythemetalthatconnectstheat

andcurvedpartsoftheblade,checktheblade

beforeusingthemachine.Ifyounoticewear,

(Figure85),replacetheblade.

g004653

Figure85

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

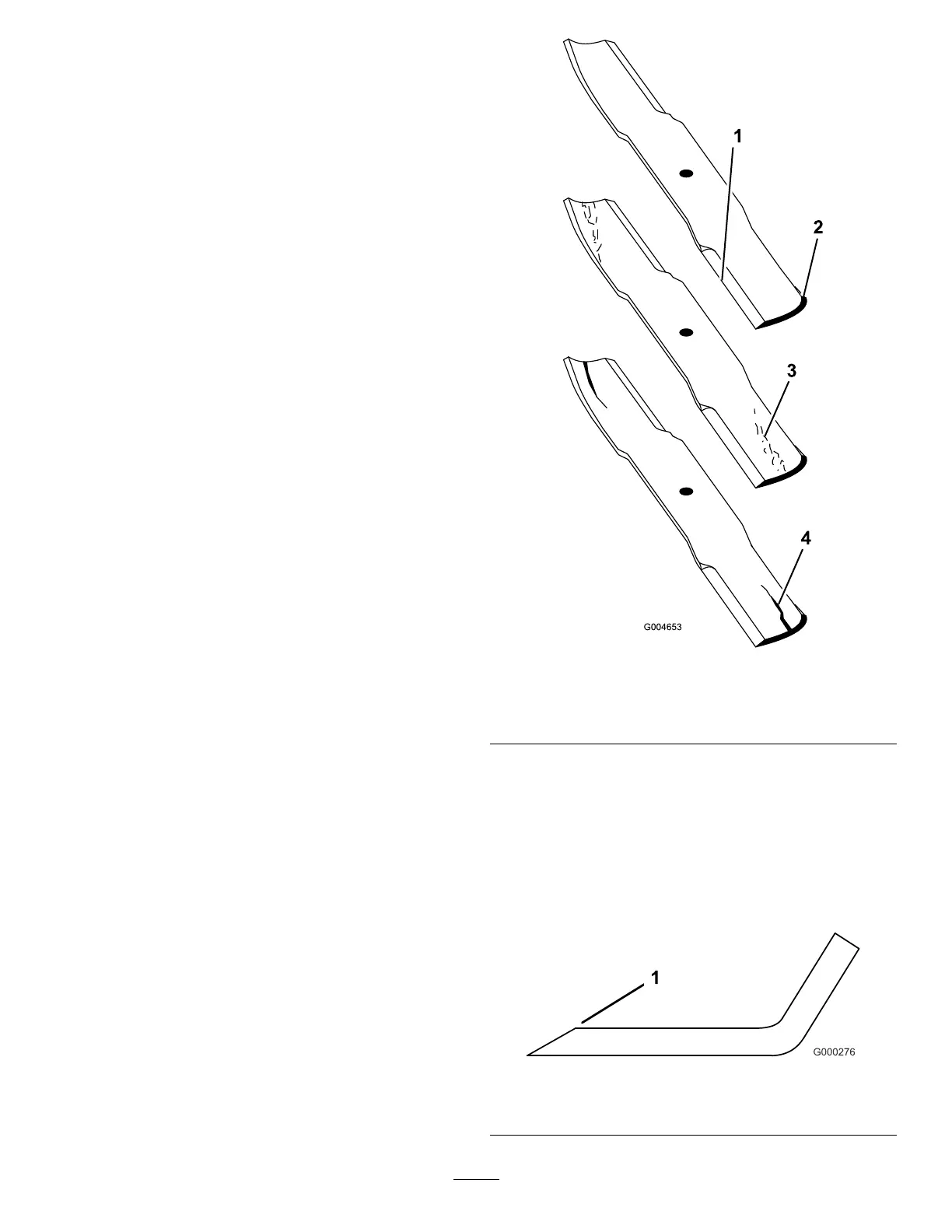

3.Examinethecuttingedgesofallthebladesand

sharpenthecuttingedgesiftheyaredullor

nicked(Figure86).

Note:Sharpenonlythetopofthecutting

edgeandmaintaintheoriginalcuttingangle

toensuresharpness(Figure86).Theblade

remainsbalancedifthesameamountofmetal

isremovedfrombothcuttingedges.

g000276

Figure86

1.Sharpenattheoriginalangle.

66

Loading...

Loading...