usuallythemosteffectivemethodforcleaning.The

sparkplugsaremostaccessiblewhentheblower

housingisremovedforcleaning.

7.Removethesparkplugs.

CheckingtheSparkPlugs

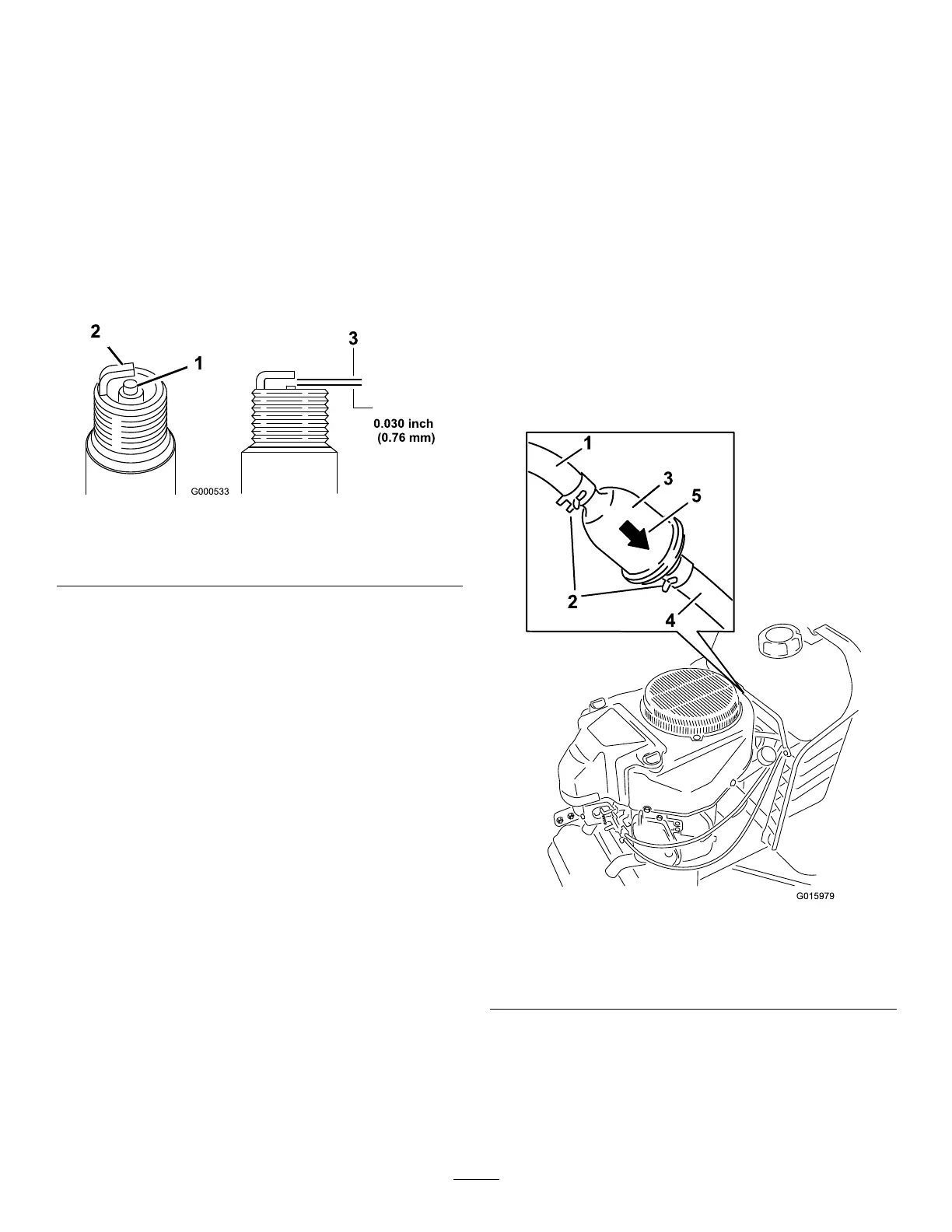

1.Inspectthesparkplugs(Figure22).

Note:Ifyouseelightbrownorgrayonthe

insulator,theengineisoperatingproperly.Ablack

coatingontheinsulatorusuallymeansthattheair

cleanerisdirty.

Figure22

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Donotcleanthesparkplugs.

Alwaysreplaceasparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(

Figure22).Bendthesideelectrodeifthegapisnot

correct.

InstallingtheSparkPlugs

1.Installthesparkplugs.

Note:Ensurethattheairgapofeachsparkplug

issetcorrectly.

2.Tightenthesparkplugsto16ft-lb(22N-m).

3.Connectthewiretoeachsparkplug.

4.Installtheshieldoverthesparkplugs.

5.Closethehood.

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours—Replacethefuel

lter.

Important:Donotinstalladirtylterifitis

removedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrol(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

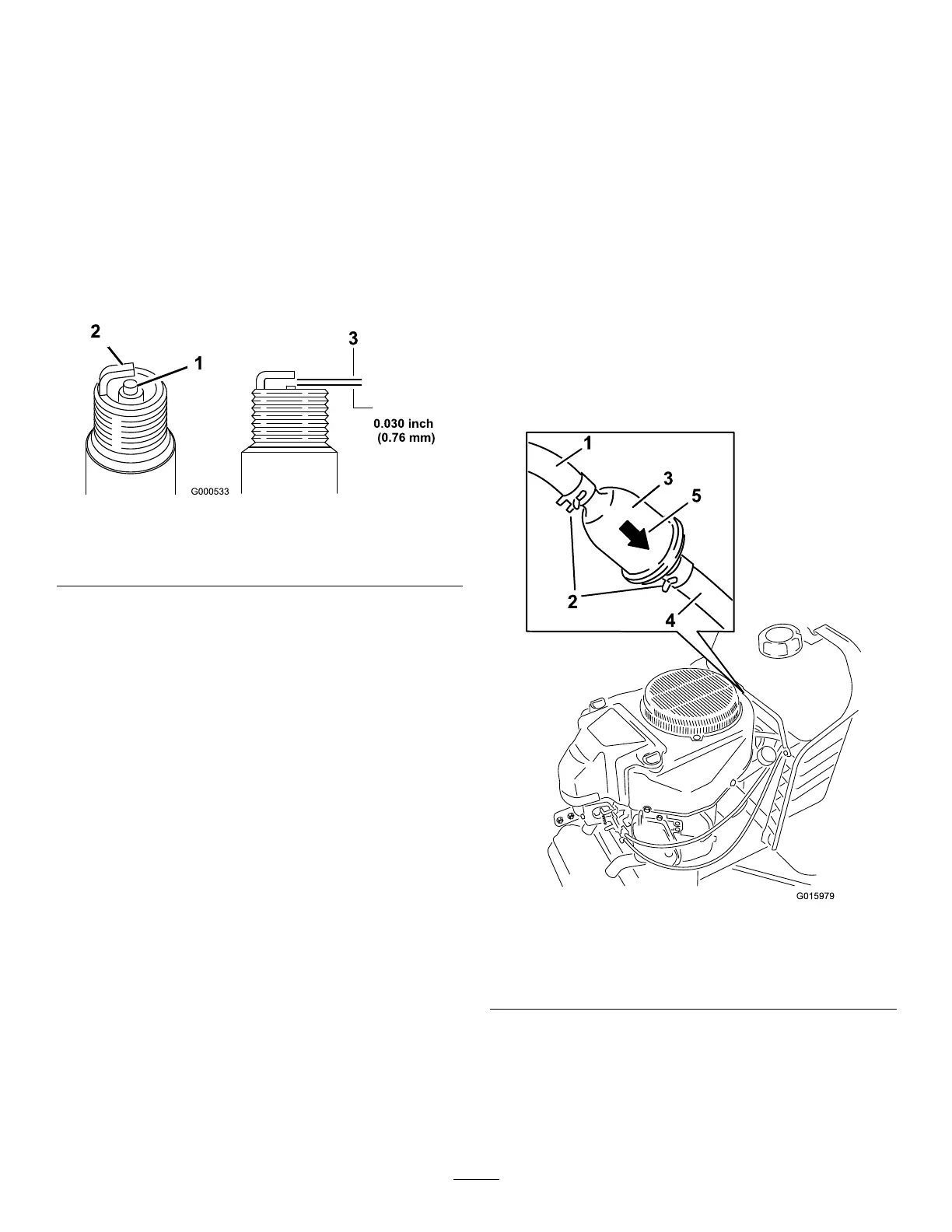

3.Raisethehoodandlocatethefuellterbetweenthe

fueltankandtheengine(

Figure23).

Figure23

1.Fuellinefromfueltank

4.Fuellinetoengine

2.Hoseclamp5.Flowdirectionarrow

3.Fuellter

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure23).

5.Removethelterfromthefuellines.

22

Loading...

Loading...