AdjustingtheTracking

1.Disengagetheblade-controlswitch(PTO).

2.Drivetoanopenatarea,movethe

motion-controlleverstotheNEUTRAL-LOCK

position.

3.MovethethrottlemidwaybetweentheFASTand

SLOWpositions.

4.Movebothmotion-controlleversalltheway

forwarduntiltheybothhitthestopsintheT-slot.

5.Checkwhichwaythemachinetracks.

6.Engagetheparkingbrake,shutofftheengine,

andremovethekey.

7.Adjustthestopplatesasneeded.

•Ifthemachinetrackstotheright,loosenthe

boltsandadjusttheleftstopplaterearward

ontheleftT-slotuntilthemachinetracks

straight(Figure60).

•Ifthemachinetrackstotheleft,loosenthe

boltsandadjusttherightstopplaterearward

ontherightT-slotuntilthemachinetracks

straight(Figure60).

8.Tightenthestopplate(Figure60).

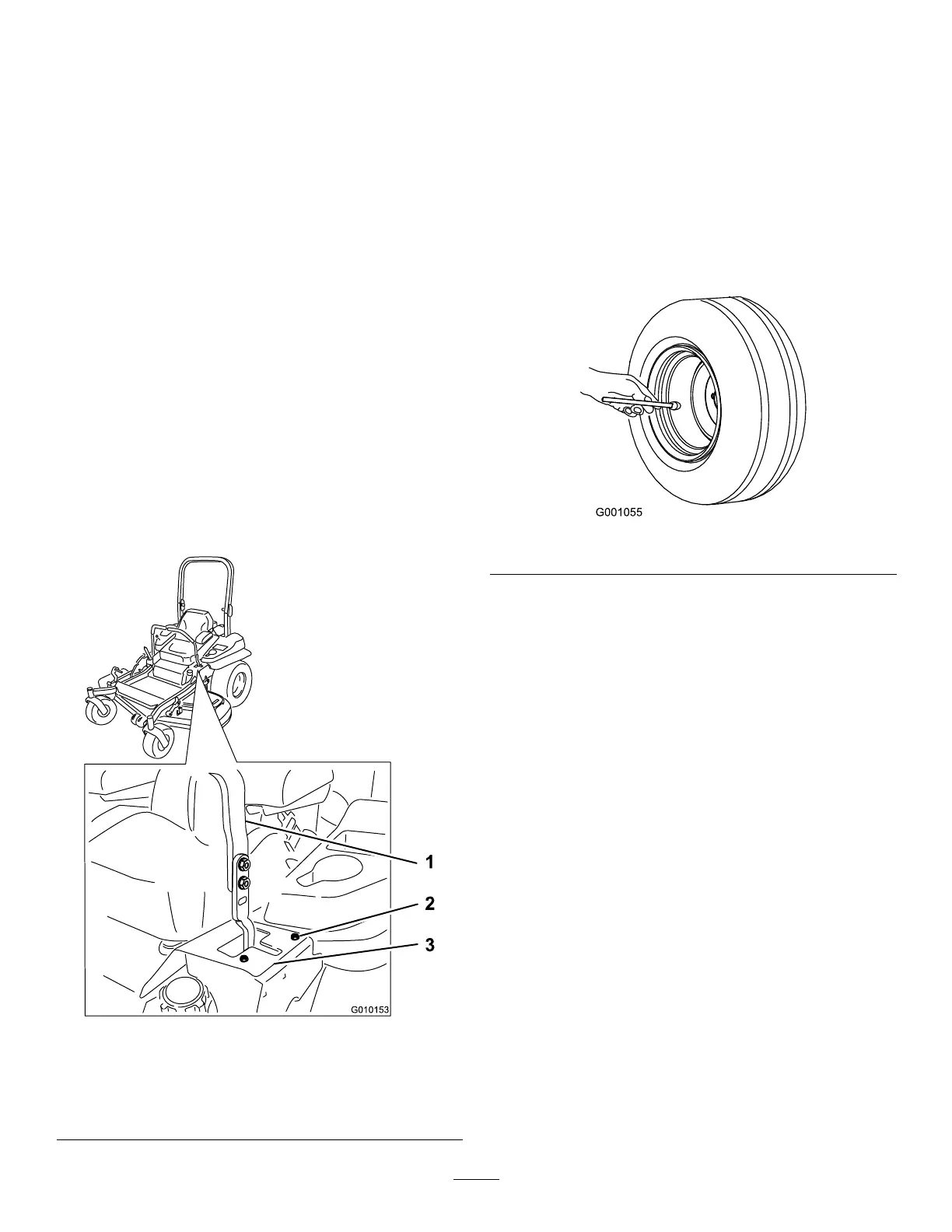

g010153

Figure60

Leftcontrollevershown

1.Controllever3.Stopplate

2.Bolt

CheckingtheTirePressure

ForMachineswithPneumatic

TiresOnly

ServiceInterval:Every50hours/Monthly(whichever

comesrst)Formachineswith

pneumatictiresonly.

Maintaintheairpressureinthecastertiresandrear

tiresat90kPa(13psi).Uneventirepressurecan

causeunevencut.Checkthetireswhentheyarecold

togetthemostaccuratepressurereading.

g001055

Figure61

CheckingtheWheelLug

Nuts

Checkandtorquethewheellugnutsto122to129

N∙m(90to95ft-lb).

48

Loading...

Loading...