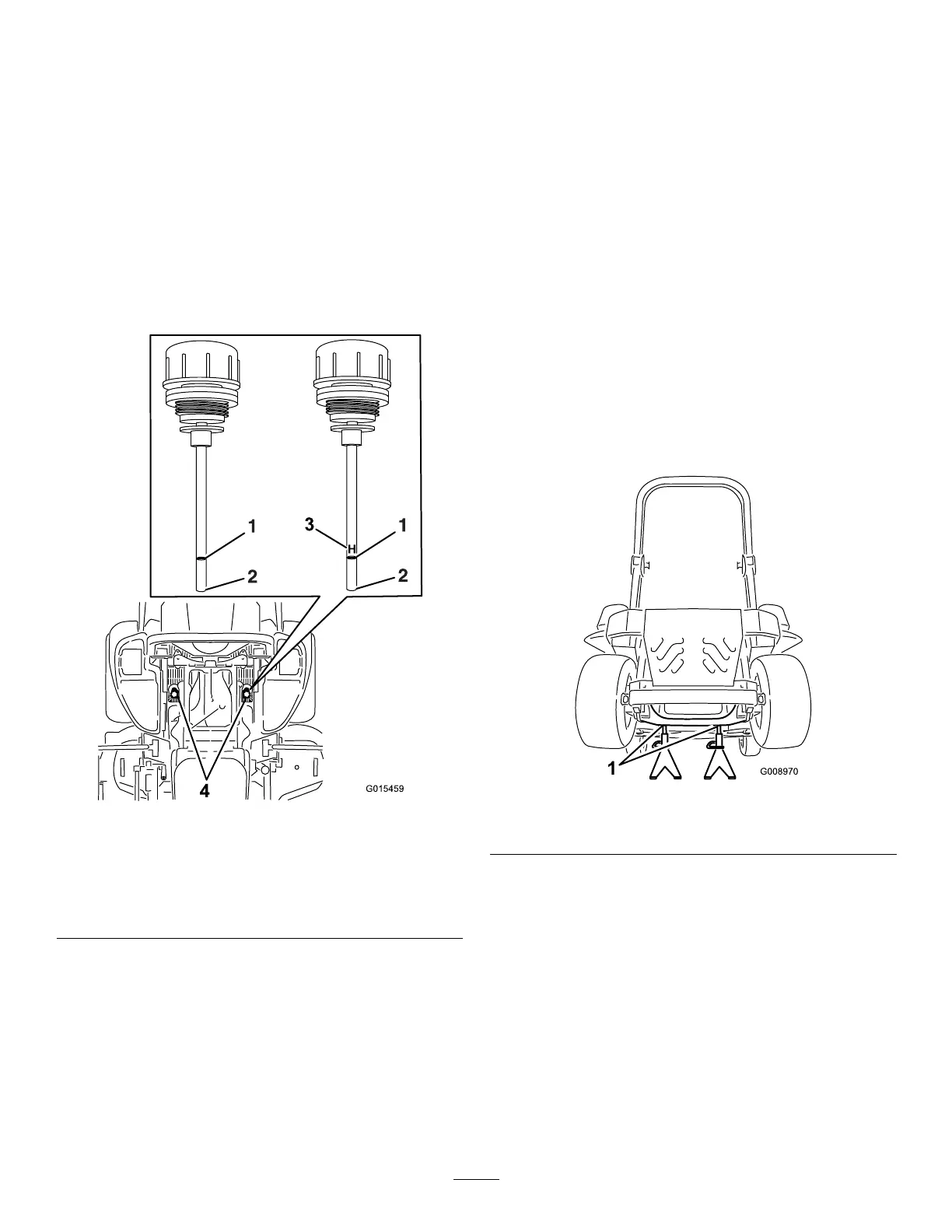

7.Wipethedipstickoffandthreadthedipstickinto

thereservoir.

8.Removethedipstickandlookattheend(Figure

83).

Important:Donotoverllthehydraulic

unitswithuid,asdamagemayoccur.Do

notrunthemachinewithuidbelowtheadd

mark.

9.Iftheuidlevelisattheaddmark,slowlypour

onlyenoughuidintothehydraulicreservoirto

raisetheleveltothefullorHline.

10.Installthedipstick.

11.Repeattheprocedurefortheoppositedipstick.

g015459

Figure83

Eitherdipstickisusedinthemachine

1.Full3.H—meanshighlevel

2.Add4.Dipsticklocationsunder

seat

ChangingtheHydraulic

FluidandFilters

ServiceInterval:Aftertherst250hours—Change

thehydraulicltersandhydraulic

uid.

Every250hours—Aftertheinitial

change—changethehydraulic-system

ltersanduidwhenusingMobil115W50

uid.(Changeitmoreoftenunderdirtyordusty

conditions)

Every500hours—Aftertheinitial

change—changethehydraulic-system

ltersanduidwhenusingT oro

®

HYPR-OIL

™

500uid.(Changeitmoreoftenunderdirtyor

dustyconditions)

Toreplacethehydraulicuid,theltersneedtobe

removed.Replacebothatthesametime;referto

Hydraulic-FluidSpecications(page58)foruid

specications.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

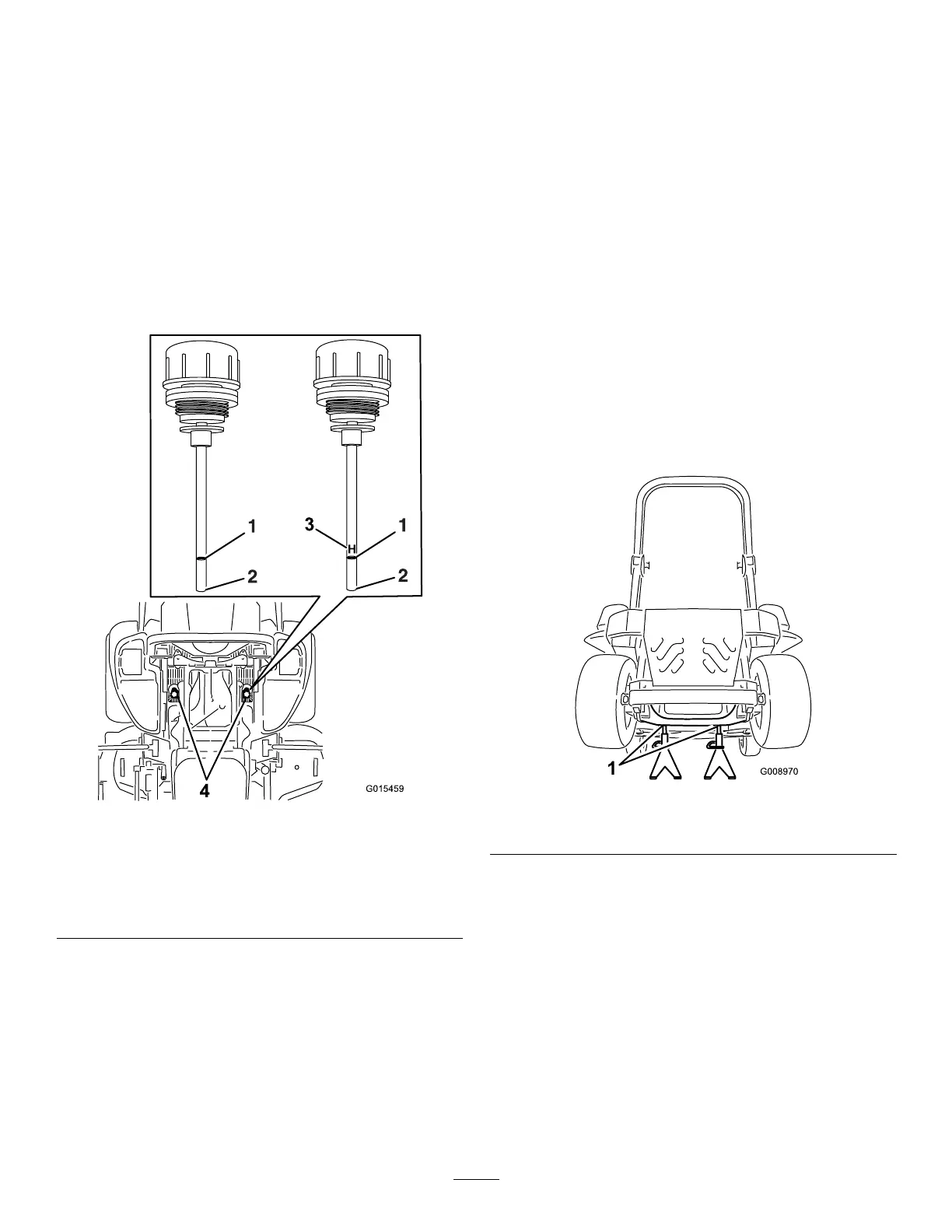

3.Raisethemachineandsupportitwithjack

stands(Figure84).

g008970

Figure84

1.Jackstands

4.Removeboththemowerbeltandthepump-drive

belt;refertoReplacingtheMowerBelt(page

54)andReplacingtheHydraulicPump-Drive

Belt(page55).

Note:Thispreventsuidfromgettingonthe

belts.

5.Placeadrainpanunderthelter,removethe

oldlter,andwipethesurfaceclean(Figure85).

59

Loading...

Loading...