EngineMaintenance

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy.

RemovingtheFoamandPaper

Elements

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrol(PTO).

2.Movethemotioncontrolleverstothebrakeposition,

stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

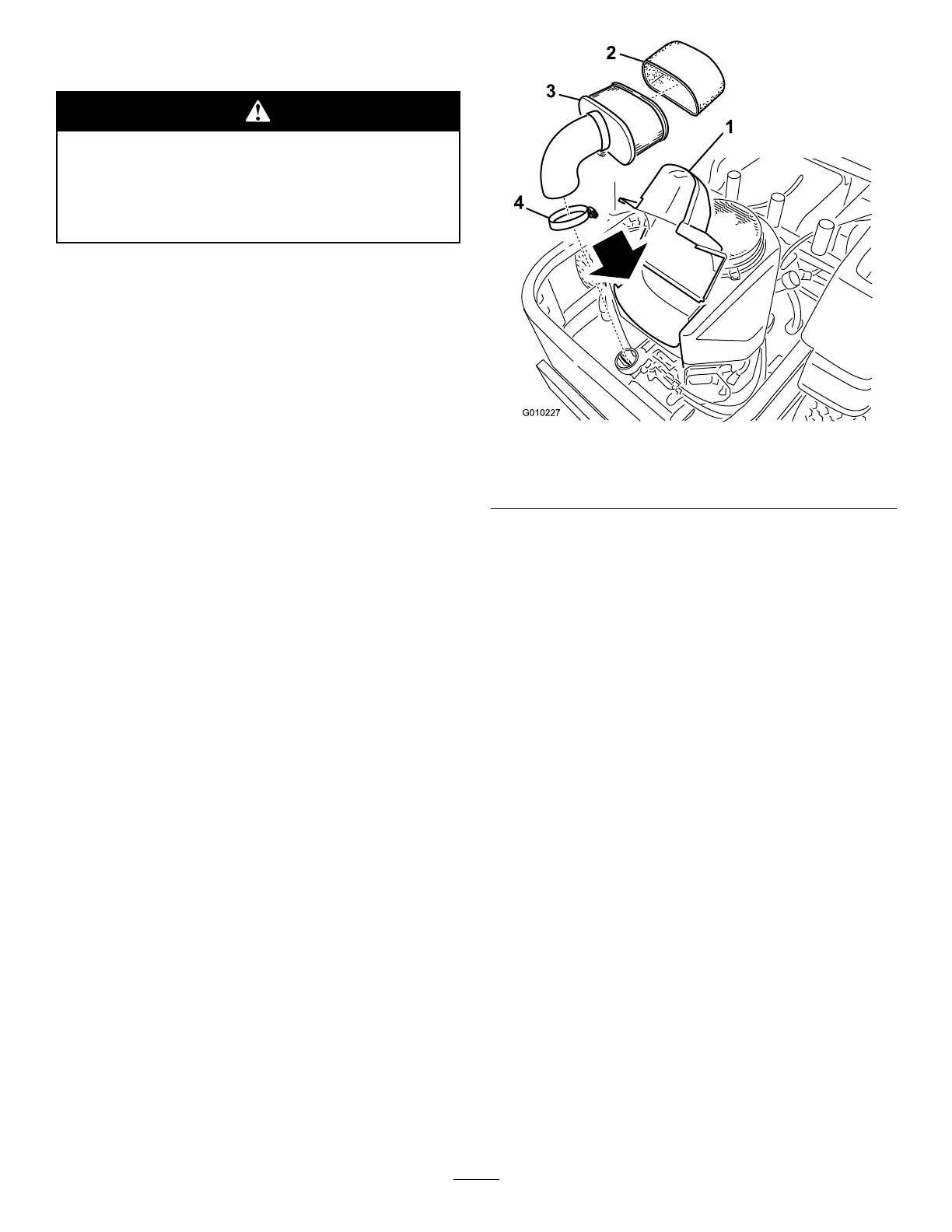

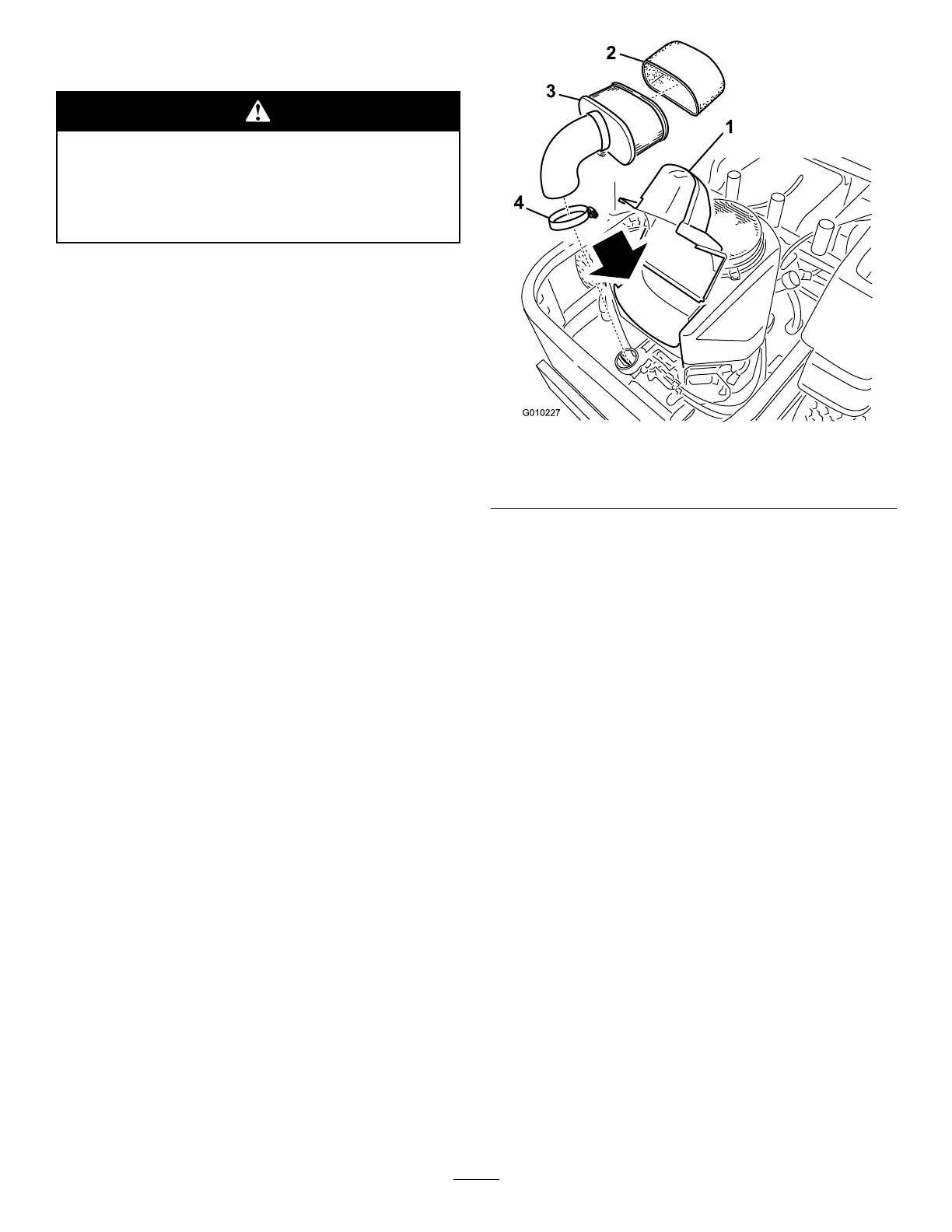

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.Loosen

thetwoplasticknobsonthecoverandremovethe

aircleanercover(Figure35).

4.Carefullyremovethefoamelementfromthepaper

element(Figure35).

5.Unscrewthewingnutsandremovethepaper

element(Figure35).

Figure35

1.Cover

3.Paperelement

2.Foamelement4.Hoseclamp

CleaningtheFoamandPaperElements

ServiceInterval:Every25hours—Servicethefoam

element.(moreoftenindusty,dirty

conditions)

Every100hours—Servicethepaper

element.(moreoftenindusty,dirty

conditions)

Every200hours/Yearly(whichever

comesrst)—Replacethepaper

element.(moreoftenindusty,dirty

conditions)

1.FoamElement

A.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

B.Drytheelementbysqueezingitinacleancloth

(donotwring).Allowtheelementtoairdry.

Important:Replacethefoamelementifit

istornorworn.

2.PaperElement

A.Lightlytaptheelementonaatsurfaceto

removedustanddirt.

B.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Nevercleanthepaperelement

withpressurizedairorliquids,suchas

31

Loading...

Loading...