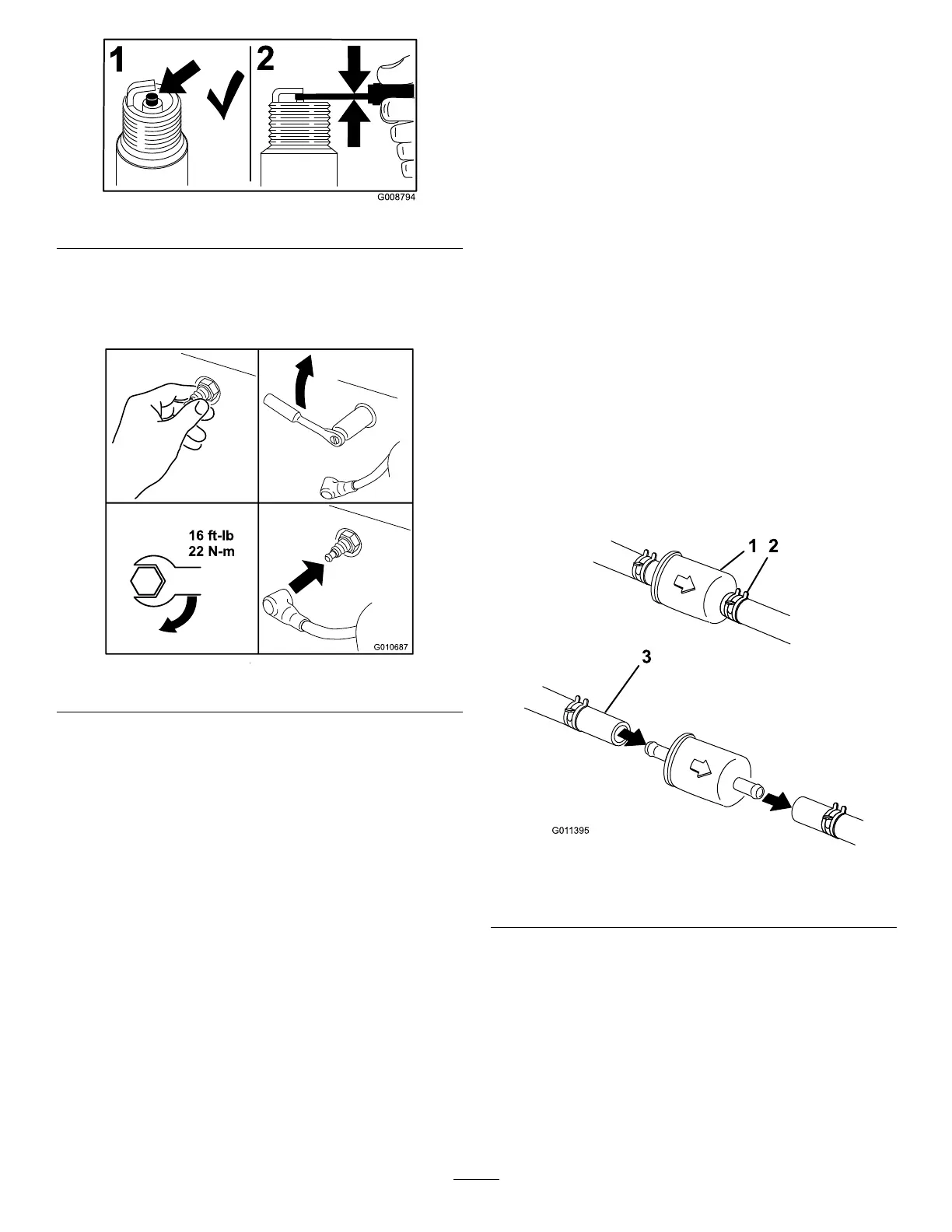

Figure42

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft-lb(22N-m).

Figure43

CleaningtheCoolingSystem

Cleantheairintakescreenfromgrassanddebrisbefore

eachuse.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionand

applytheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,and

fanhousing.

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichever

comesrst)(moreoftenunderdusty,

dirtyconditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure44).

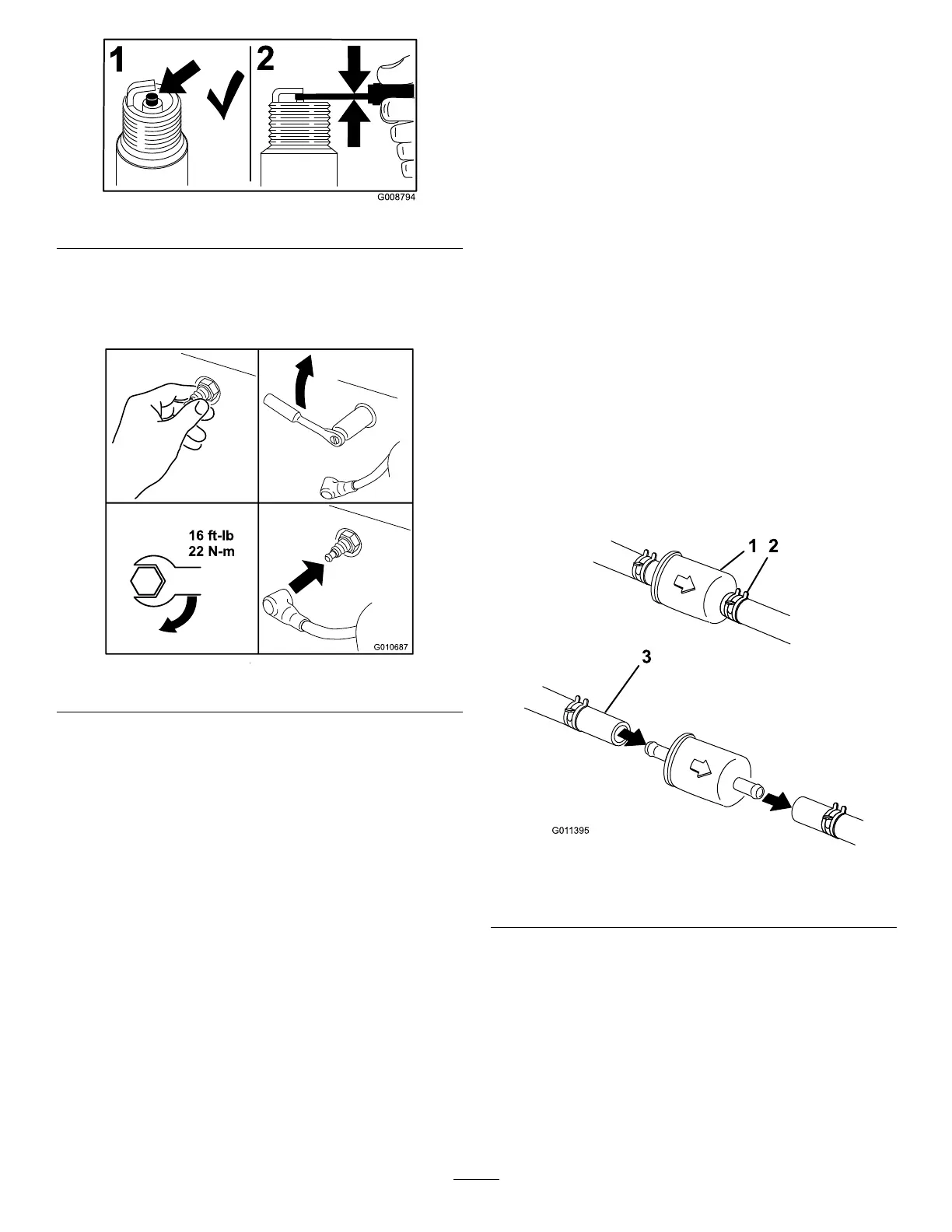

Figure44

1.Fuellter

3.Fuelline

2.Hoseclamp

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampsclose

tothelter(Figure44).

8.Openthefuelshutoffvalve.

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

35

Loading...

Loading...