InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter(

Figure48).

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4

to1fullturn(Figure48).

3.Repeatstep2fortheotherlter.

4.Alignthelterguardsovereachlter;refertostep4of

RemovingHydraulicSystemFilters(page37).

5.Securethelterguardswiththe3screwsremovedin

step4ofRemovingHydraulicSystemFilters(page

37)Usethethreescrewstosecurethelterguards.

6.Addoiltothehydraulicsystemasfollows:

A.Ensurethattheventplugsandreservoircapare

removedbeforeaddingtheoil(Figure46and

Figure47).

B.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneofthevent

plugholesandstoplling(Figure47).

C.Installthatventplug(Figure47).

Note:Torquetheplugto20.3N-m(180in-lb).

D.Addoilthroughtheexpansionreservoiruntiloil

comesoutoftheremainingventplugholeonthe

secondtransmissionandstoplling(Figure47).

E.Installthatventplug(Figure47).

Note:Torquetheplugto20.3N-m(180in-lb).

7.Addoilthroughtheexpansionreservoiruntilitreaches

theFULLCOLDlineontheexpansionreservoirand

installthecapforthereservoir(Figure46).

8.Bleedthehydraulicsystem;refertoBleedingthe

HydraulicSystem(page38).

Important:Failuretoperformthe

Bleeding

the Hy draulic System

procedureafterchanging

hydraulicltersandoilmayresultinirreparable

damagetothetransaxledrivesystem.

BleedingtheHydraulicSystem

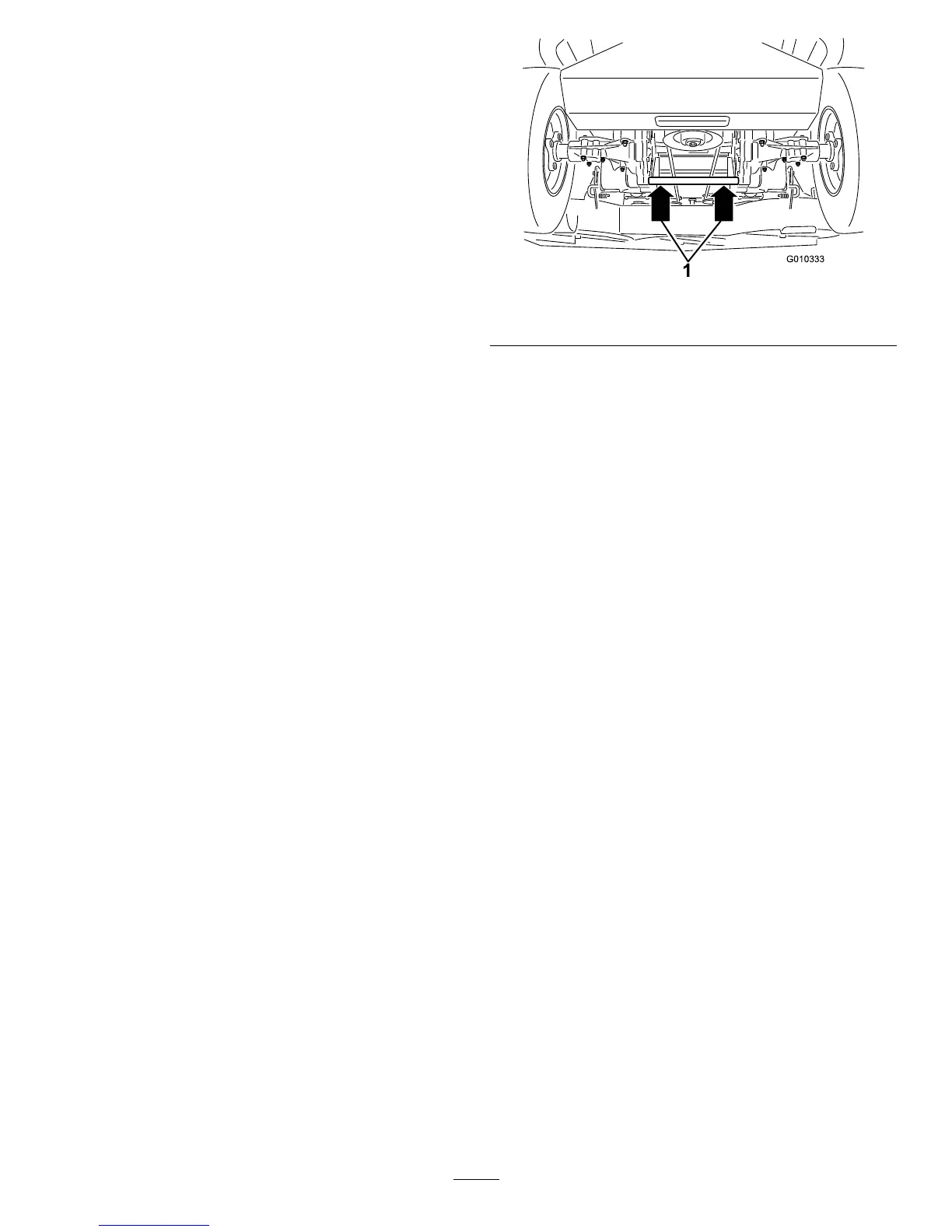

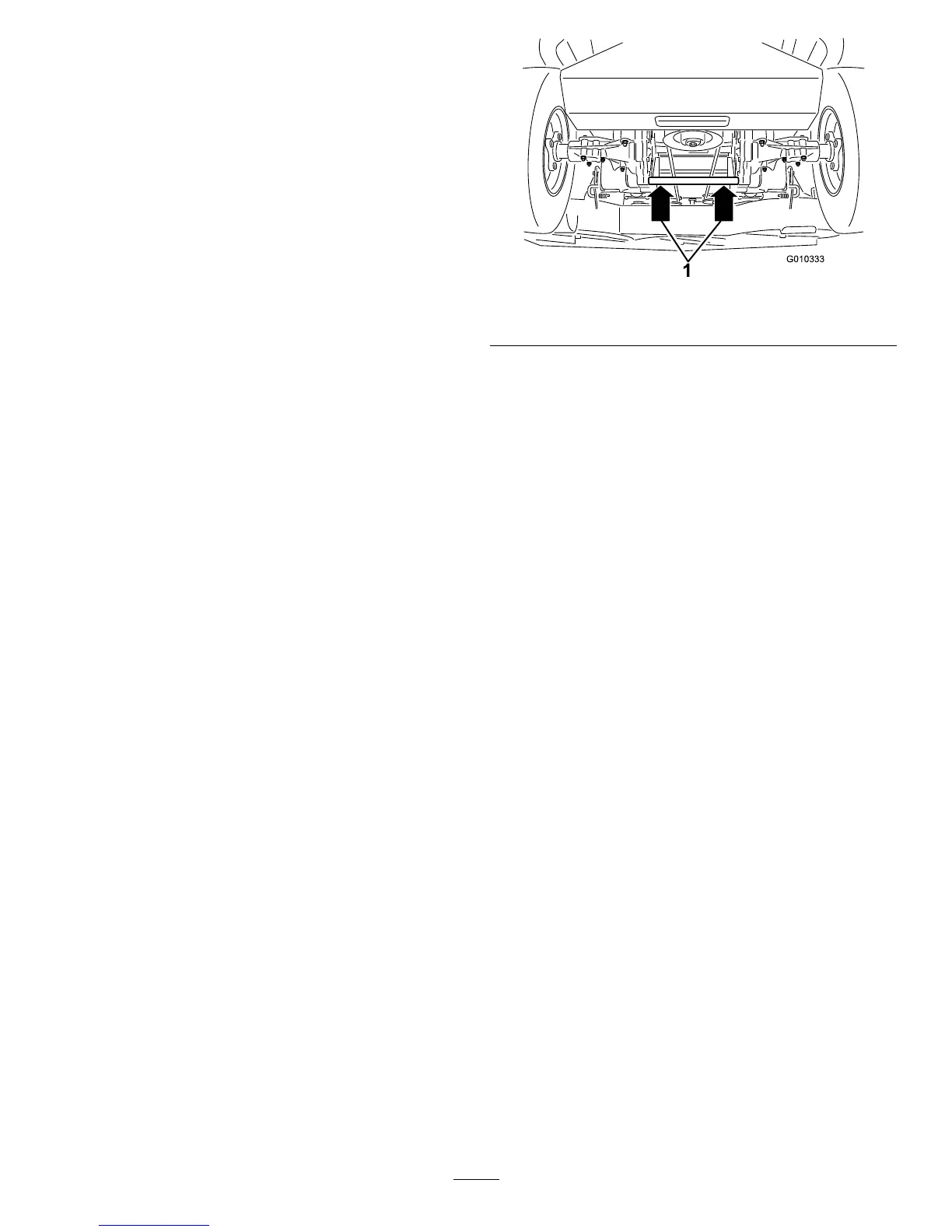

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

Figure49

1.Jackingpoints

2.Gototheoperator'sposition.

3.Startengineandmovethrottlecontrolaheadto1/2

throttleposition.

4.Disengageparkingbrake.

5.Cyclethehydraulicsystembyperformingthefollowing:

A.Movethebypassleversrearwardandthendown

tolocktheminplace(valveopenposition);refer

toToPushtheMachine(page24).

B.Withthebypassvalvesopenandtheengine

running,slowlymovethemotioncontrolleversin

bothforwardandreverse(5or6times).

C.Movethebypassleversuptounlockthemand

forward(valveclosedposition);refertoToPush

theMachine(page24).

D.Withthebypassvalveclosedandtheengine

running,slowlymovethedirectionalcontrolin

bothforwardandreversedirections(5to6times).

6.Stoptheengineandchecktheoillevelintheexpansion

reservoir.Addthespeciedoilasuntilitreachesthe

FULLCOLDlineontheexpansionreservoir(Figure

46).

7.Repeatstep5untilalltheairiscompletelypurgedfrom

thesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

8.Checktheoillevelintheexpansionreservoironelast

time.AddthespeciedoilasuntilitreachestheFULL

COLDlineontheexpansionreservoirifnecessary

(

Figure46).

38

Loading...

Loading...