RemovingtheClutchShim

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey.

2.Engagetheparkingbrakeandallowthemachineto

cool.

3.Usinganaircompressor,blowoutanydebrisfrom

underthebrakepoleandaroundthebrakespacers.

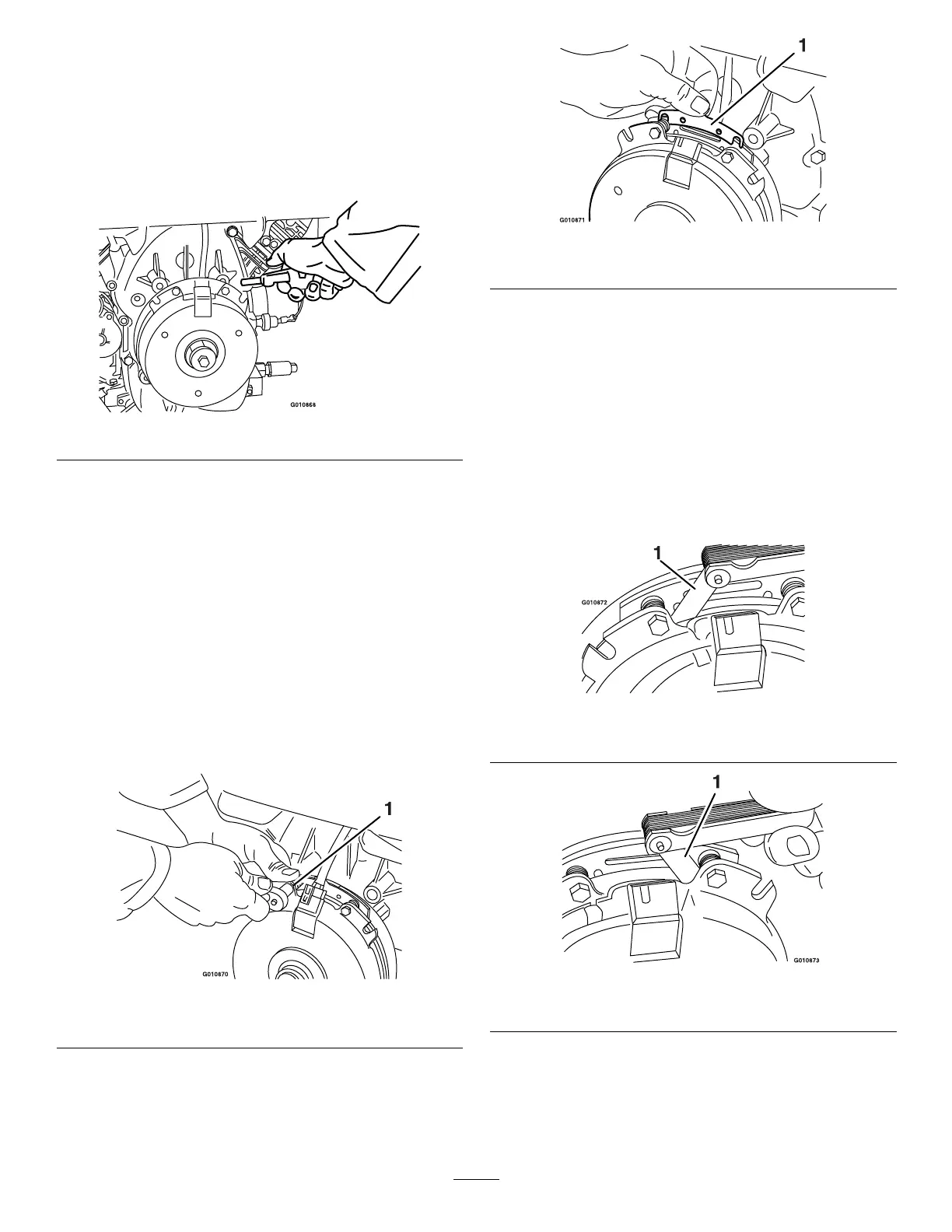

Figure71

4.Checktheconditionofthewireharnessleads,

connectors,andterminals.Cleanorrepairasnecessary.

5.Verifythat12Vispresentattheclutchconnectorwhen

thePTOswitchisengaged.

6.Measurethegapbetweentherotorandthearmature.

Ifthegapisgreaterthan1mm(0.04inch),proceed

withthefollowingsteps:

A.Loosenbothbrakemountingboltsone-halfto

onefullturnasshownbelow.

Note:Donotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn

tomatchthearmatureandneedstocontinueto

matchaftertheshimisremovedtoensureproper

braketorque.

Figure72

1.Brakemountingbolt

B.Usingneedle-nosepliers,orbyhand,takeholdof

thetabandremovetheshim.

Note:Donotdiscardtheshimuntilproper

clutchfunctionhasbeenconrmed.

Figure73

1.Shim

C.Usingapneumaticline,blowoutanydebris

fromunderthebrakepoleandaroundthebrake

spacers.

D.Re-torqueeachbolt(M6x1)to13N-m(10ft-lb)

+/-0.7N-m(0.5ft-lb).

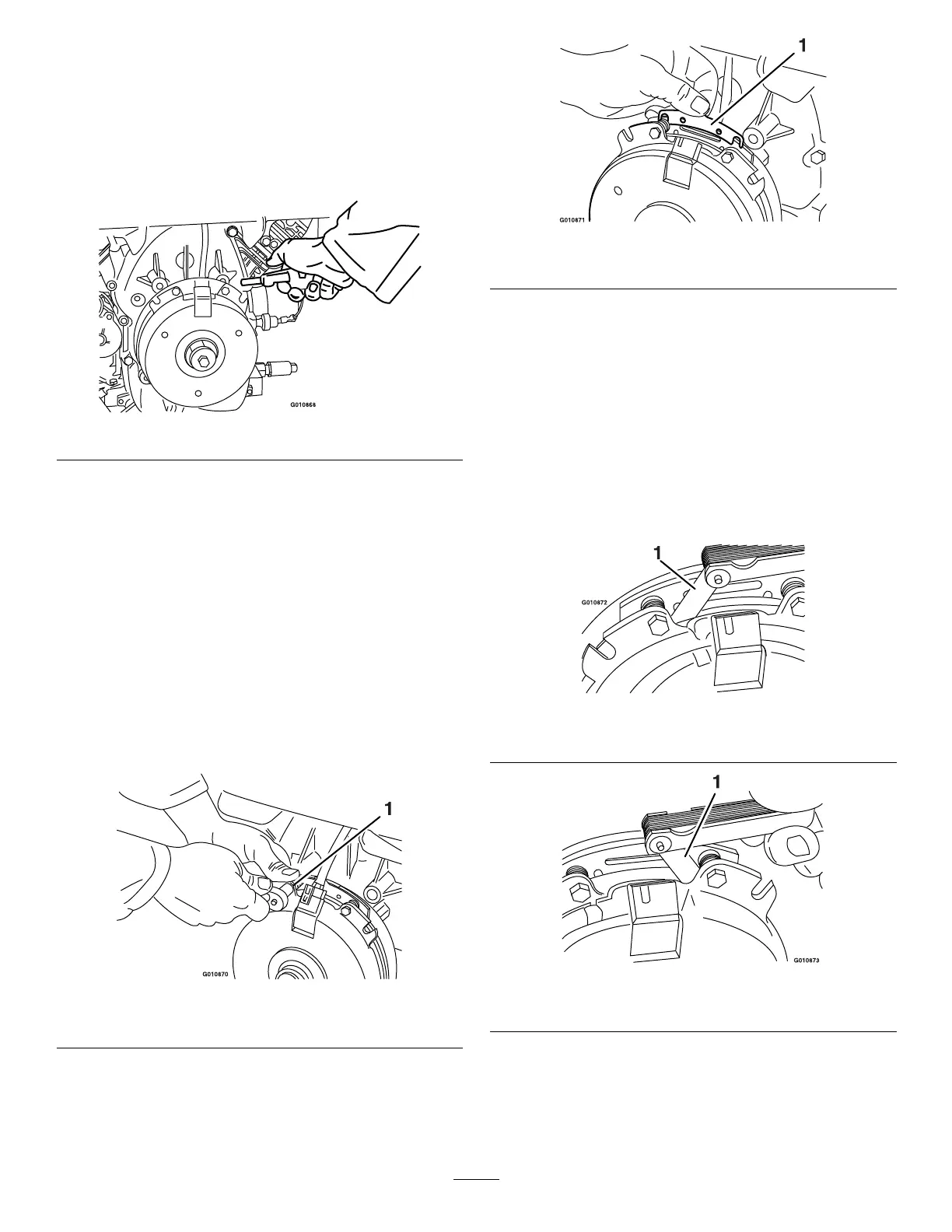

E.Usinga0.010inchthickfeelergauge,verifythat

agapispresentbetweentherotorandarmature

faceonbothsidesofthebrakepoleasshown.

Note:Duetothewaytherotorandarmature

faceswear(peaksandvalleys)itissometimes

difculttomeasurethetruegap.

Figure74

1.Feelergauge

Figure75

1.Feelergauge

•Ifthegapislessthan0.010inch,thenreinstall

theshimandreferencetheTroubleshooting

section.

•Ifthegapissufcient,proceedtothesafety

checkinstep

F.

46

Loading...

Loading...