8.Wipethedipstickoffandthreadthedipstickinto

thereservoir.

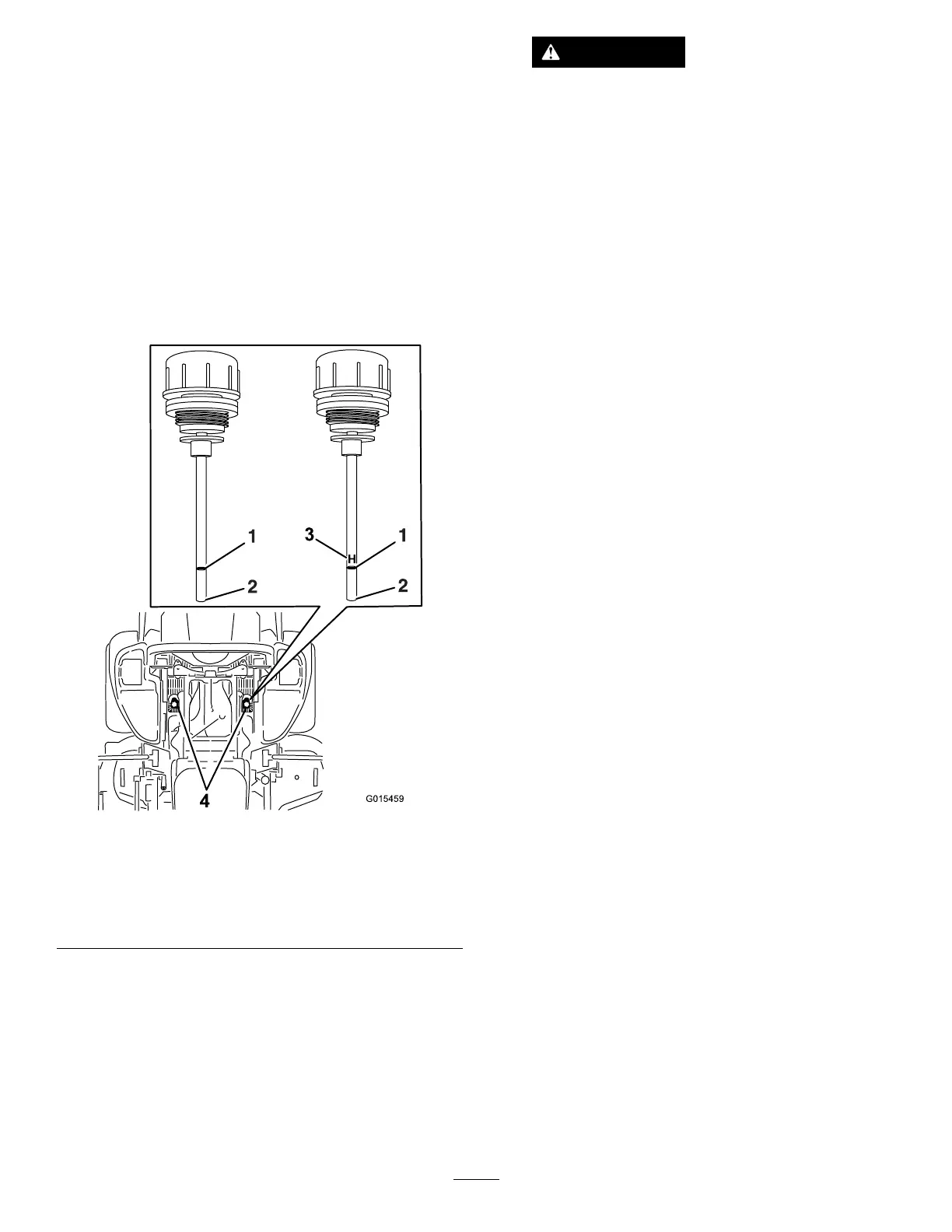

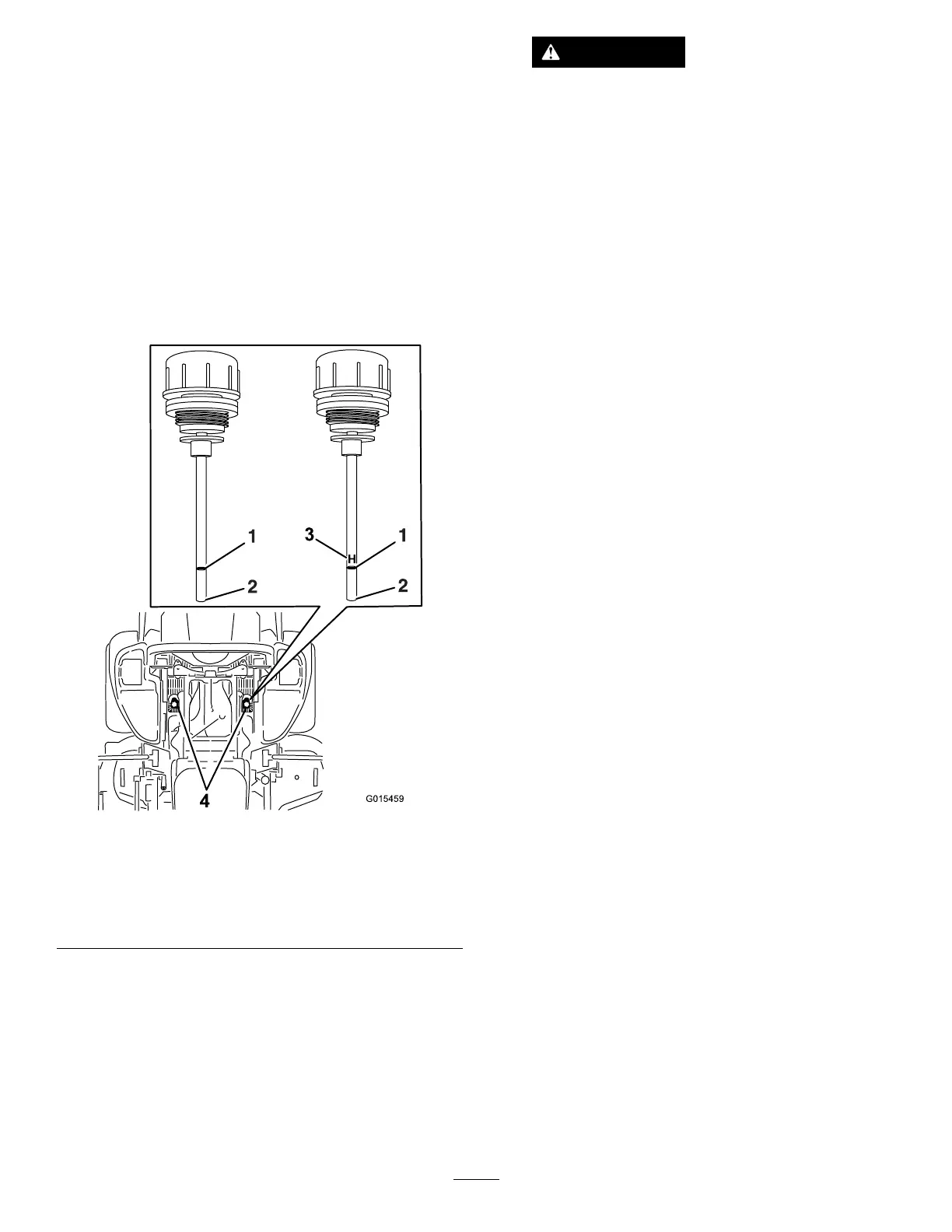

9.Removethedipstickandlookattheend(Figure

88).

Important:Donotoverllthehydraulic

unitswithoilasdamagemayoccur.Donot

runthemachinewiththeoilbelowtheadd

mark.

10.IftheoillevelisattheAddmark,slowlypour

onlyenoughoilintothehydraulicreservoirto

raisetheleveltotheFullorHline.

11.Installthedipstick.

12.Repeattheprocedurefortheoppositedipstick.

g015459

Figure88

Eitherdipstickisusedinthemachine

1.Full3.Hmeanshighlevel

2.Add4.Dipsticklocationsunder

seat

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintothe

skinitmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliar

withthistypeofinjury.Gangrenemay

resultifthisisnotdone.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertond

hydraulicleaks.

•Safelyrelieveallpressureinthe

hydraulicsystembeforeperforming

anyworkonthehydraulicsystem.

•Makesurethatallhydraulichoses

andlinesareingoodcondition,and

allhydraulicconnectionsandttings

aretightbeforeapplyingpressureto

thehydraulicsystem.

61

Loading...

Loading...