g004178

Figure10

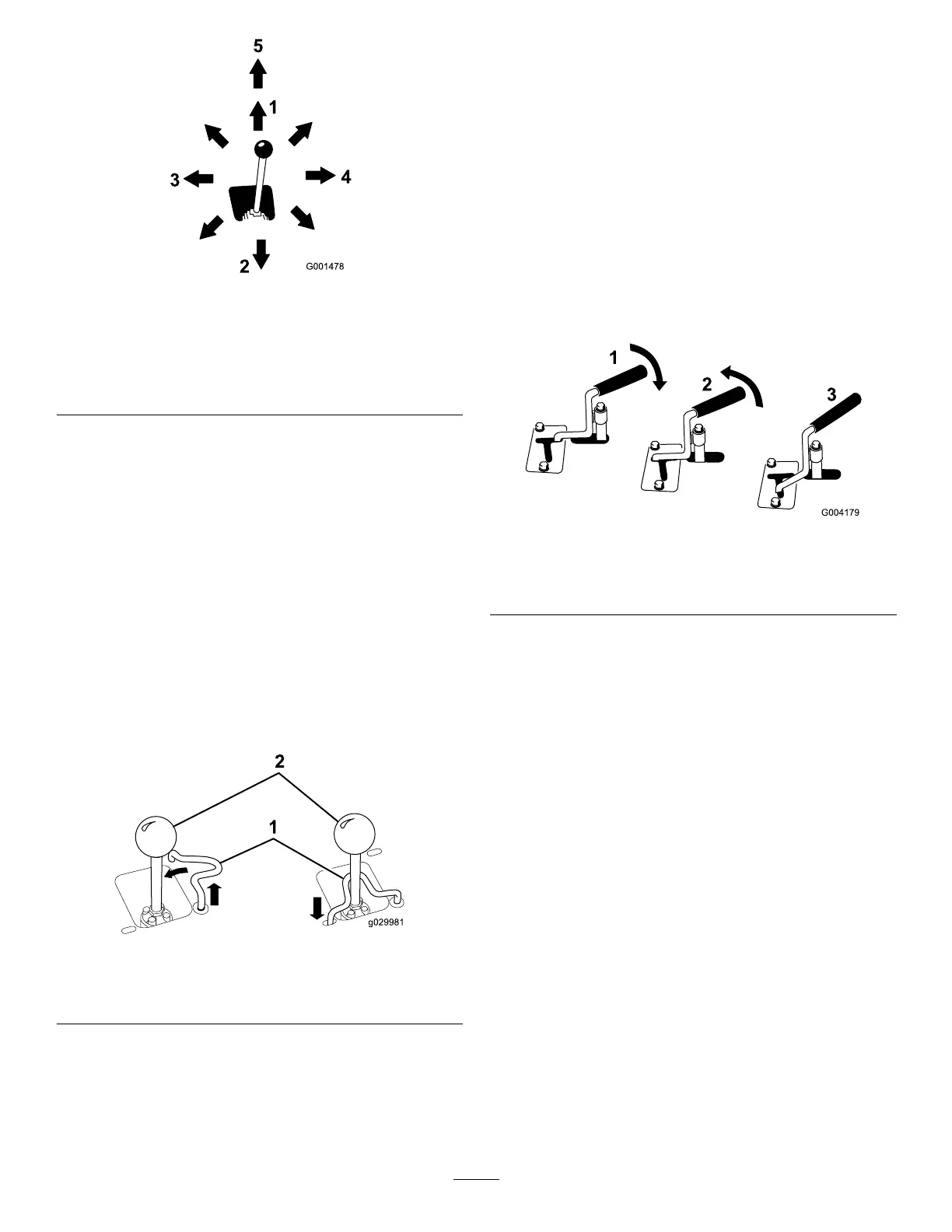

1.Detent(oat)position

4.Tilttheattachment

rearward.

2.Lowertheloaderarms.5.Tilttheattachment

forward.

3.Raisetheloaderarms.

Bymovingthelevertoanintermediateposition(e.g.,

forwardandleft),youcanmovetheloaderarmsand

tilttheattachmentatthesametime.

Loader-ValveLock

Theloader-valvelocksecurestheloader

arm/attachment-tiltleversothatyoucannotpushit

forward.Thishelpstoensurethatnooneaccidentally

lowerstheloaderarmsduringmaintenance.Secure

theloaderarmswiththelockanytimeyouneedto

shutoffthemachinewiththeloaderarmsraised.

Tosetthelock,liftuponitsothatitclearstheholein

thecontrolpanelandswingittotheleft,infrontof

theloader-armlever,pushingitdownintothelocked

position(Figure11).

g029981

Figure11

1.Loaderarm/attachment-tilt

lever

2.Loader-valvelock

Loader-Control-ReferenceBar

Theloader-control-referencebarhelpsstabilizeyour

handwhileoperatingtheloaderarm/attachment-tilt

lever(Figure4).

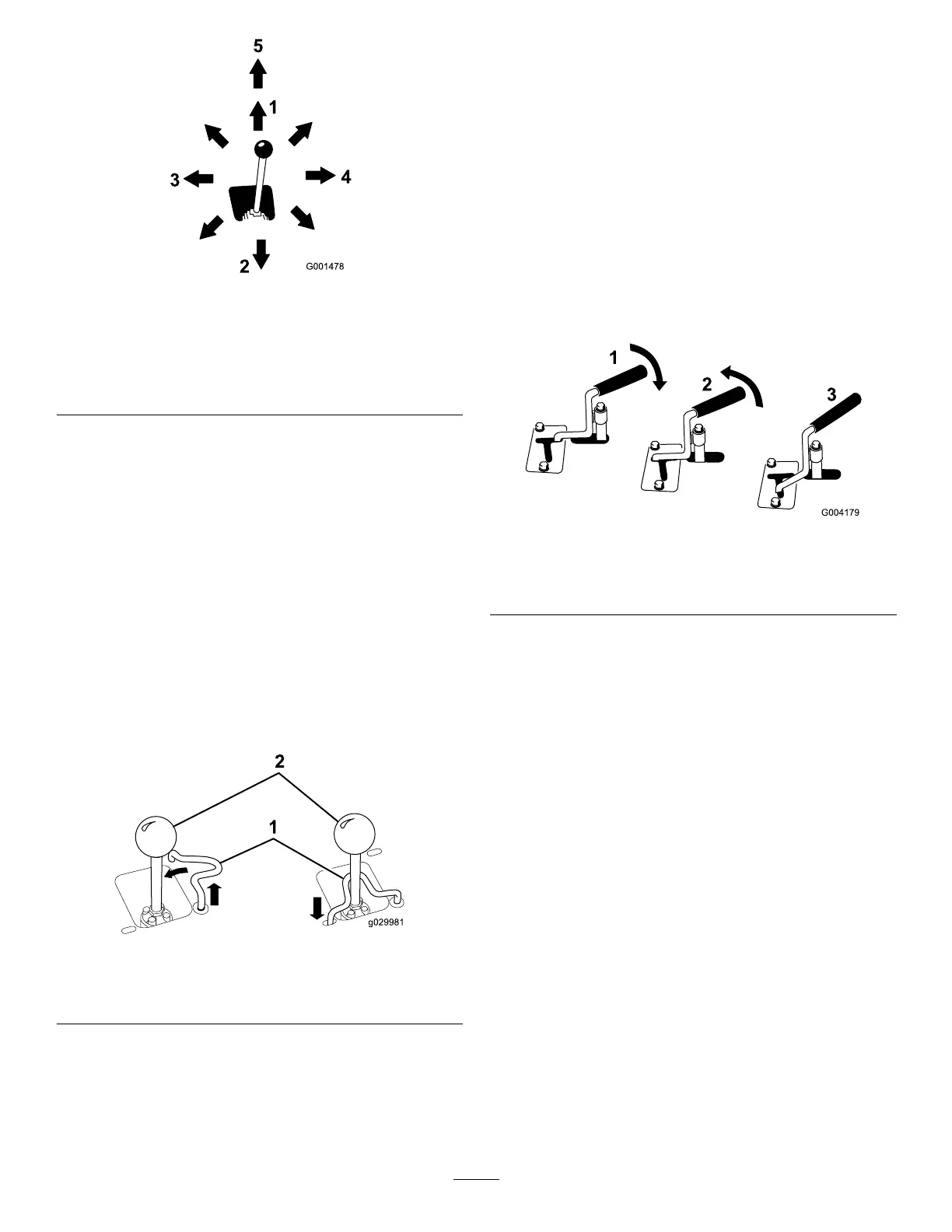

Auxiliary-HydraulicsLever

•Tooperateahydraulicattachmentintheforward

direction,rotatetheauxiliary-hydraulicslever

rearwardandpullitdowntothereferencebar

(Figure12,number1).

•Tooperateahydraulicattachmentinthereverse

direction,rotatetheauxiliary-hydraulicslever

rearward,thenmoveitleftintotheupperslot

(Figure12,number2).

Note:IfyoureleasetheleverwhileintheFORWARD

position,theleverautomaticallyreturnstothe

NEUTRALposition(Figure12,number3).Ifitisinthe

REVERSEposition,itremainsthereuntilyoupullitout

oftheslot.

g004179

Figure12

1.Forward-owhydraulics

3.Neutral

2.Reverse-owhydraulics

HourMeter/Tachometer

Whentheengineisoff,thehourmeter/tachometer

displaysthenumberofhoursofoperationloggedon

themachine.Whentheengineisrunning,itdisplays

thespeedoftheengineinrevolutionsperminute

(rpm).

After50hoursandthenevery100hoursthereafter

(i.e.,150,250,350,etc.)thescreendisplaysCHG

OILtoremindyoutochangetheengineoil.

Afterevery100hours,thescreendisplaysSVC

toremindyoutoperformtheothermaintenance

proceduresbasedona100-,200-,or400-hour

schedule.

Note:Theseremindersappear3hourspriortothe

serviceintervaltimeandashatregularintervalsfor

6hours.

11

Loading...

Loading...