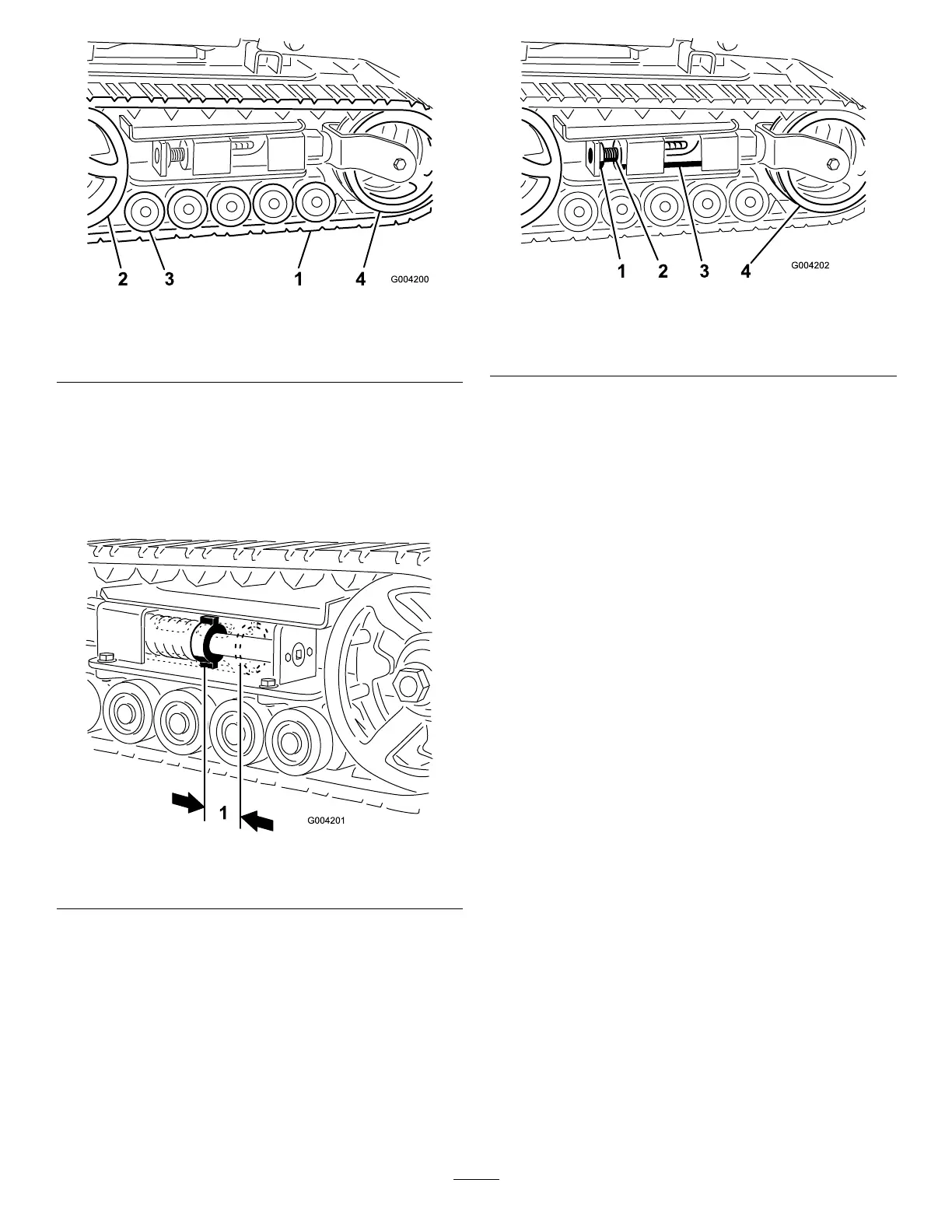

g004200

Figure45

1.Track3.Roadwheels

2.Drivesprocket4.Tensionwheel

AdjustingtheTrackTension

Thereshouldbe7cm(2-3/4inches)betweenthe

tensionnutandthebackofthetensiontube(Figure

46).Ifnot,adjustthetracktensionusingthefollowing

procedure:

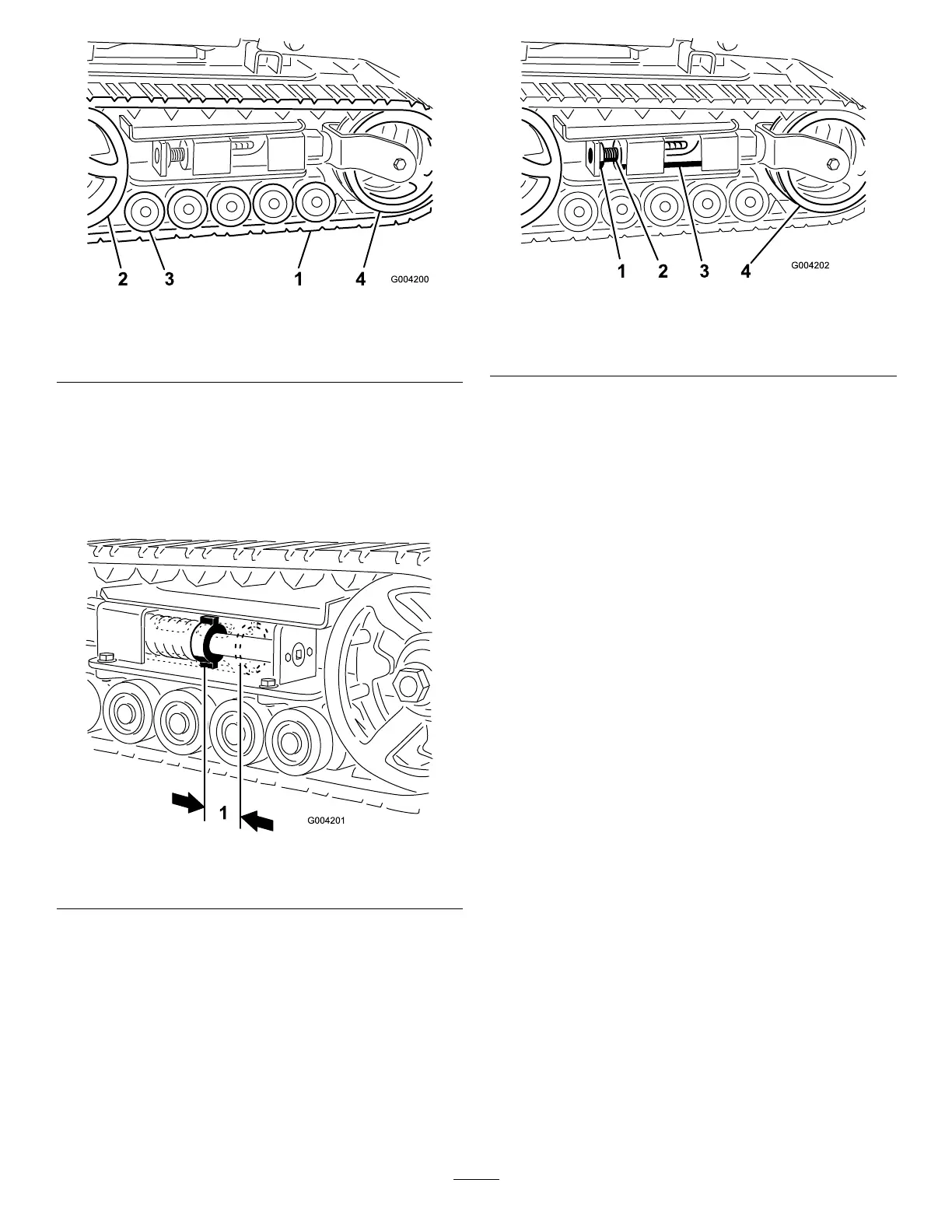

g004201

Figure46

1.7cm(2-3/4inches)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackisofftheground.

4.Removethelockingboltandnut(Figure47).

g004202

Figure47

1.Lockingbolt3.Tensiontube

2.Tensioningscrew4.Tensionwheel

5.Usinga1/2-inchdriveratchet,turnthe

tensioningscrewcounterclockwiseuntilthe

distancebetweenthetensionnutandtheback

ofthetensiontube(Figure46)is7cm(2-3/4

inches).

6.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingboltandnut(Figure47).

7.Lowerthetractionunittotheground.

ReplacingtheTracks

ReplacingNarrow-WidthTracks

Whenthetracksarebadlyworn,replacethem.

Note:Youhavenarrow-widthtracksifthefront

tensionwheelsaremountedinsideaforkontheend

ofthetensiontube(Figure48).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackis8to10cm(3to4inches)

offtheground.

4.Removethelockingboltandnut(Figure47).

5.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure47andFigure48).

35

Loading...

Loading...