70

Refrigerant pipe installation

Vacuuming

Leak position check

If a pressure drop is detected, check for leakage at connecting points. Locate the leakage by listening,

feeling, using foaming agent, etc. - then rebraze or retighten.

Air purge

The air purge must be completed before supplying power to ensure the Multi Controller’s PMVs are

open.

Using a vacuum pump, complete an air purge. Never use refrigerant gas.

• After the airtight test, discharge the nitrogen gas.

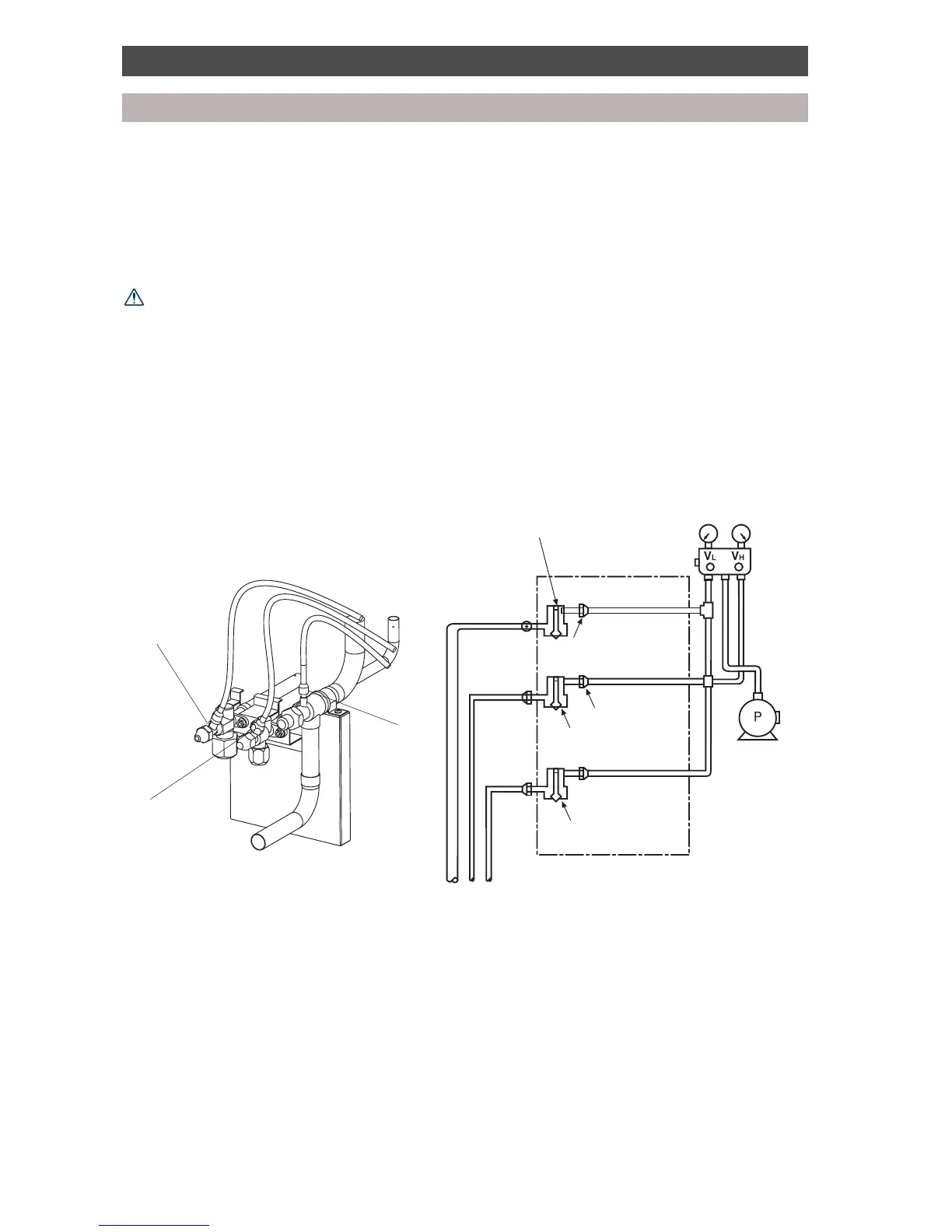

• Connect a gauge manifold to the service port at discharge gas, liquid and suction gas sides, and

connect a vacuum pump as shown.

• Be sure to vacuum at discharge gas, liquid and suction gas sides.

Low

pressure

gauge

High

pressure

gauge

Packed valve fully closed

(gas suction side)

Inverter outdoor unit

Gauge

manifold

Brazed

Service port

Vacuum pump

Service port

Flare

connection

Flare

connection

Packed valve fully

closed (liquid side)

Packed valve fully closed

(gas discharge side)

• Use a vacuum pump with high vacuum carry-over degree (-0.013 x 10

5

Pa; 0.750 mm Hg or less) and

large displacement (40 l/min. or more).

• Ensure to create a vacuum at -0.013 x 10

5

Pa (0.75 mm Hg) at the discharge gas, liquid and suction

gas.

• After the procedure has been completed, replace the vacuum pump with a refrigerant bottle and add

the refrigerant if required.

Detailed drawing of packed valve

Service port at gas

discharge side

Service port at

liquid side

Service port at

gas suction side

To

manifold

Loading...

Loading...