5

1. Introduction

The TQC Sheen Glossmeter enables you to measure the gloss level of different

surfaces such as paint, coating, plastic and ceramics.

The gloss level is determined by projecting light onto the surface at a specific angle

and measuring the light that it reflects. The angle at which the light is projected is

important. The light shall be projected onto the surface at an angle matching the

surface's average gloss level. A scan angle is therefore usualy specified for the

various surfaces. The 60º angle is the reference angle and can be used for every

surface, from matte to mirror finish. The 20º scan angle achieves the best results on

high-gloss surfaces, whereas the 85º scan angle works best on matte surfaces.

Accurate measurements can only be achieved on flat and clean surfaces.

Measurements on soiled, scratched or otherwise contaminated test objects are

useless, except to determine the degree of imperfection. Because it is unlikely that

the gloss output is the same across the entire test surface, you should measure the

gloss in a number of places and determine the standard deviation.

Note:

The aluminum particles in effect and metallic lacquers can produce different results.

The TQC Sheen glossmeter comes in three versions:

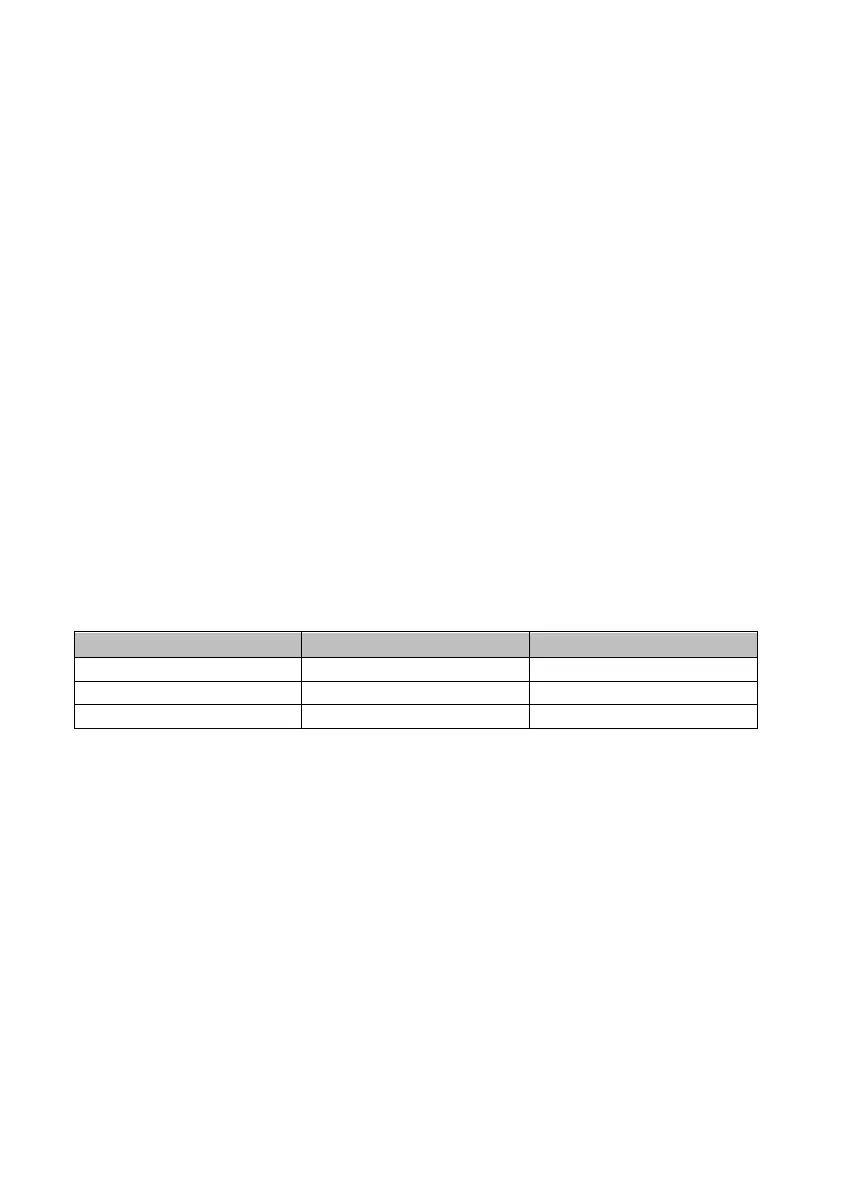

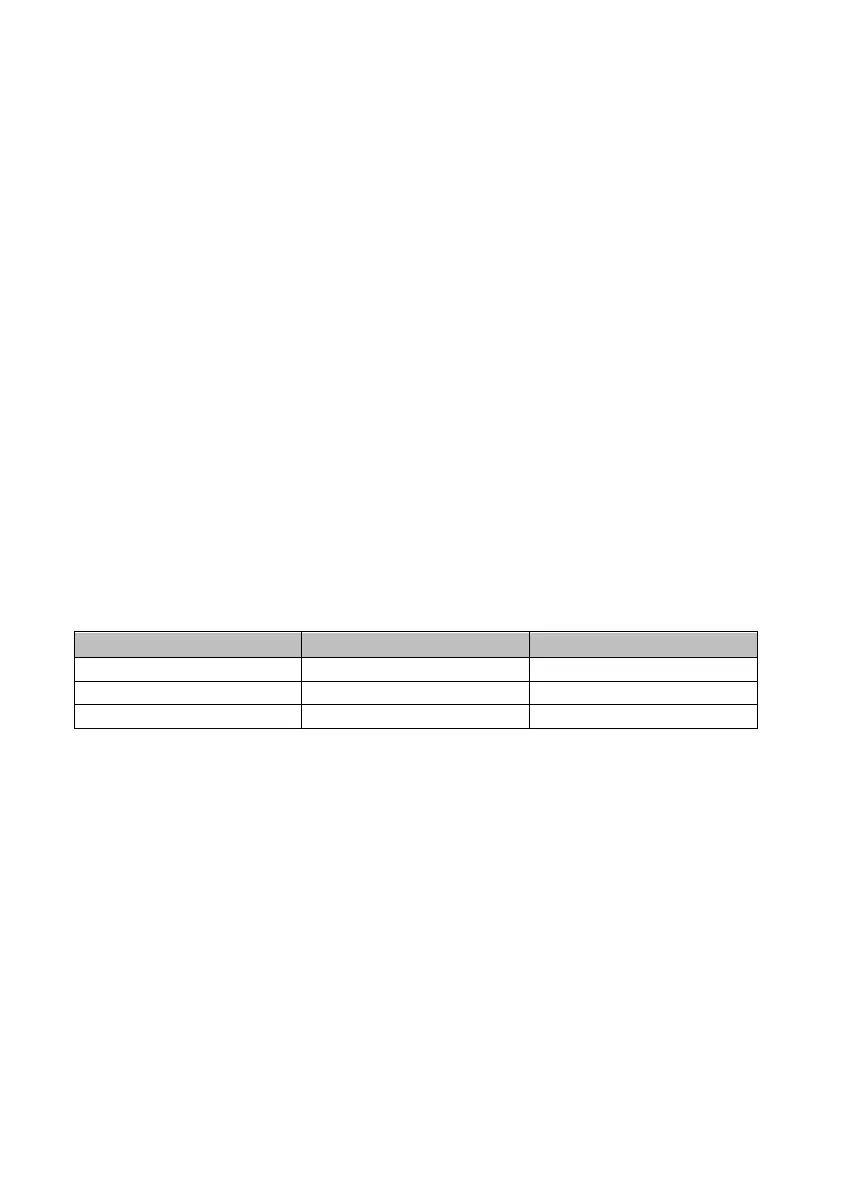

Article Number Model name Measuring angles

GL0010 TQC Sheen SoloGloss 60°

GL0020 TQC Sheen DuoGloss 20°/60°

GL0030 TQC Sheen PolyGloss 20°/60°/85°

The TQC Sheen Glossmeter's memory is large enough to store a maximum of 2000

measurements of three angles each in 8 batches. One batch can contain up to a

maximum of 500 measurements, which can be transferred to a PC by connecting it

to the glossmeter with a USB cable. You can also read measurements from the TQC

Sheen Glossmeter's screen. The settings (Setup) can be protected by a password.

Glossmeters are internationally standardized instruments to ensure that

measurements produced by any of the devices can be compared with each other.

Loading...

Loading...