5

GB

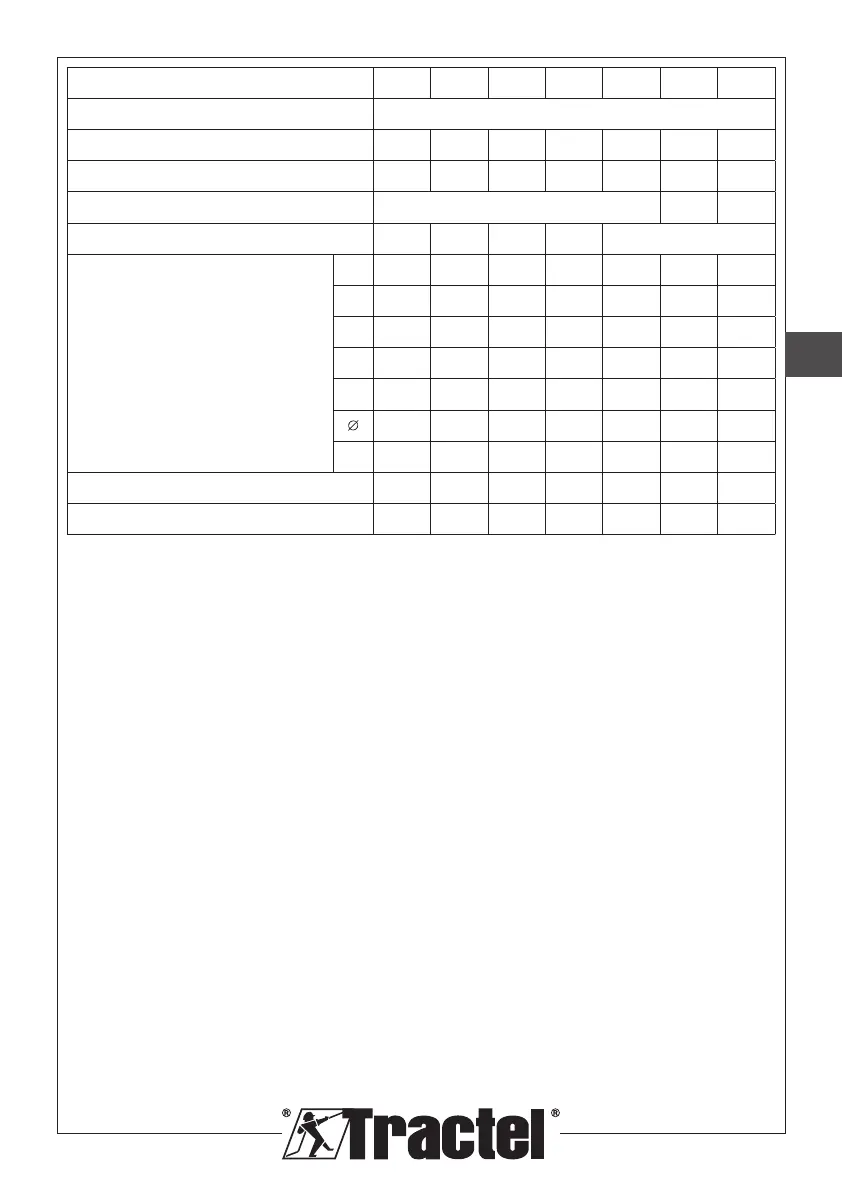

WLL* (t) 0.5 0.75 1 1.5 3 6 9

Standard lifting height** (m)

1.5

Minimum distance between hook H (mm) 260 325 325 380 480 620 700

Maximum force on handle at WLL* (N) 340 140 190 220 320 340 360

Number of strands 1 2 3

Chain dimensions (type T) 5 × 15 6 × 18 6 × 18 8 × 24 10 × 30

Dimensions (mm)

A 105 148 148 172 200 200 200

B 78 90 90 98 115 115 115

C 80 136 136 160 180 235 319

D 300 280 280 410 410 410 410

E 21 25 25 27 37 41 55

34 40 40 44 54 66 83

M 42 47 47 50 67 78 92

Net weight (kg)

4 7 7 11 21 31 44

Additional weight by lifting m. (kg) 0.54 0.8 0.8 1.4 2.2 4.4 6.6

** : other travel distances possible : 3 m; 4.5 m; 6 m.

Optionally, the bravo™ hoists of W.L.L.* 0.75 t / 1 t / 1.5 t / 3 t / 6 t / 9 t an be equipped with a dynamic load limiter adjusted between

1.1 and 1.9 × WLL*. The load limiter mechanism is integrated in the lever and is formed by friction disks and a clamping nut by which

the limiter is adjusted. This adjustment is performed by TRACTEL

®

.

3. INSTALLATION

Before installing the bravo™ hoist make the following

checks:

1. Check that the hoist is in good condition.

2. Check that the correct hoist capacity is to be used.

3. Check that the hooks and safety latches are in good

condition.

4. Check that the low limit stop is in place.

5. When the hoist uses a multiple strand chain, make

sure that the strands are not tangled or twisted.

6. Check that the load chain is correctly tted.

7. Check that the anchor point is sufcient to take the

intended load.

After successfully completing the preliminary checks,

install the bravo™ hoist on its anchoring point and

perform the following checks:

1. Check that the bravo™ hoist is properly suspended

by its suspension hook (item 5, g. 1) and that the

hook safety catch (item 6, g. 1) is properly closed

(see gs. 2 and 3).

2. Check that the load chain has not been subjected to

any torsion when setting up, in particular for the two-

strand version (see g. 4).

3. Without load, check that the up and down functions

operate correctly.

4. When using the hoist with a push suspension trolley,

without load, check that the trolley moves freely. If

using a geared suspension trolley, without load,

check the direction of movement by pulling on the

trolley hand chain. The movement should be carried

out on a strictly horizontal plane.

After successfully completing these checks, place the

load in position and ensure:

1. The anchoring accessory of the load sits fully in the

hook and does not prevent the catch from closing

correctly (see gs. 2 and 3).

2. The load on the hoist is free to align itself with the

machine’s anchoring point.

Loading...

Loading...