Installation

22 PART-SVN228B-EN

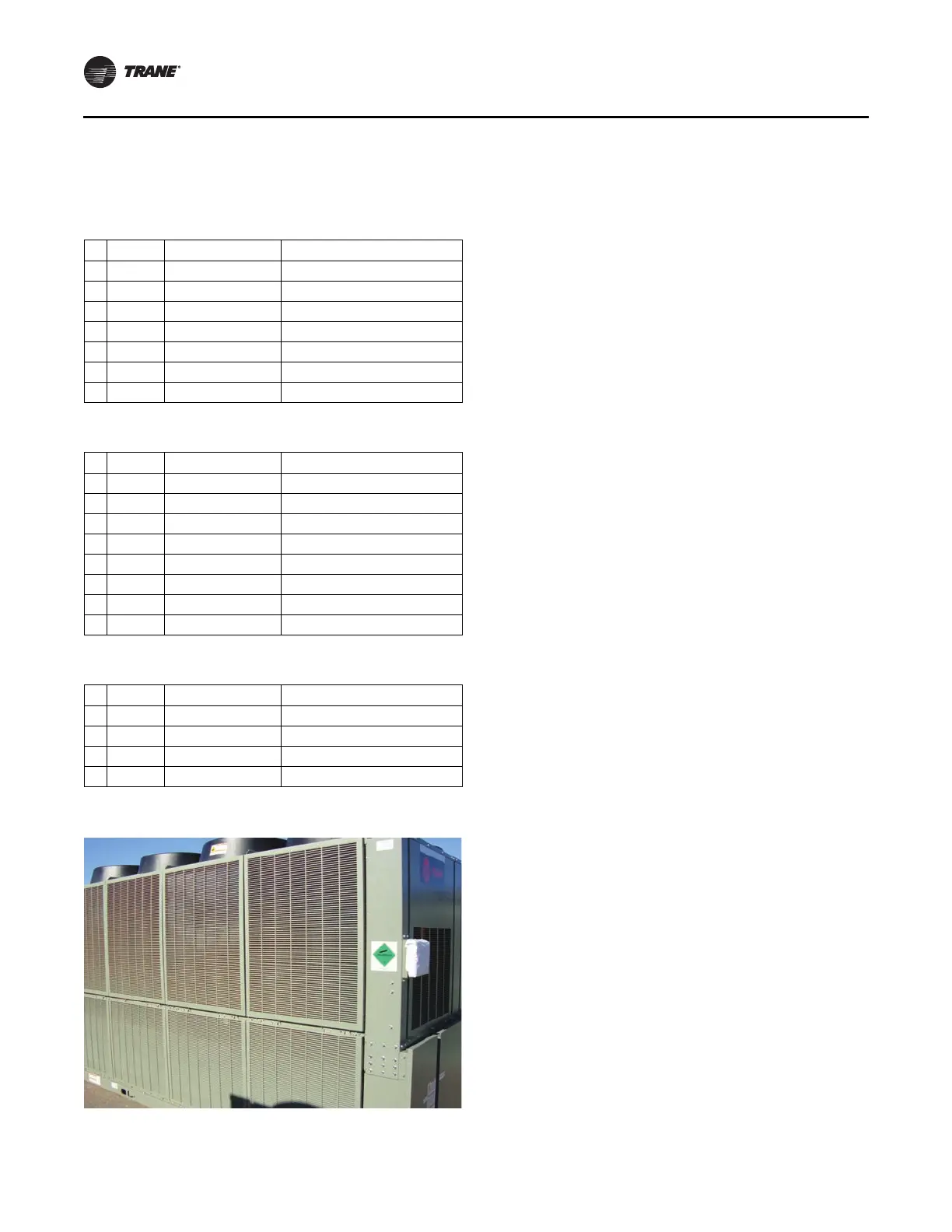

CGAM100, CGAM110, and

CGAM120 Chillers (W2 Units)

Table 26. Kit contents FMF14464

# Qty Per Component Part Component Description

1 8 571272480100 PANEL; LVRD UPPER PLASTIC

2 24 X32030872010 CLIP-SPEED; S Type Spring

3 40 X25020604010 SCREW;M8 X 1.25MM X 16MM

4 2 572024130100 ANGLE; LOUVER

5 8 572055580100 LOUVER; LOWER SIDE CGAM

6 1 572018650100 ANGLE; LOUVER

7 2 572055570100 LOUVER; LOWER END CGAM

Table 27. Kit contents LVR01106

# Qty Per Component Part Component Description

1 8 571272480100 PANEL; LVRD UPPER PLASTIC

2 24 X32030872010 CLIP-SPEED; S Type Spring

3 40 X25020604010 SCREW;M8 X 1.25MM X 16MM

4 2 572024130100 ANGLE; LOUVER

5 8 572055580100 LOUVER; LOWER SIDE CGAM

6 1 572018650100 ANGLE; LOUVER

7 1 572229070100 PANEL; LOUVER W

8 1 572229090100 PANEL; LOUVER, W w/PMP

Table 28. Kit contents LVR01105

# Qty Per Component Part Component Description

1 8 571272480100 PANEL; LVRD UPPER PLASTIC

2 24 X32030872010 CLIP-SPEED; S Type Spring

3 24 X25020604010 SCREW;M8 X 1.25MM X 16MM

4 2 572055550100 LOUVER; UPPER SIDE CGAM

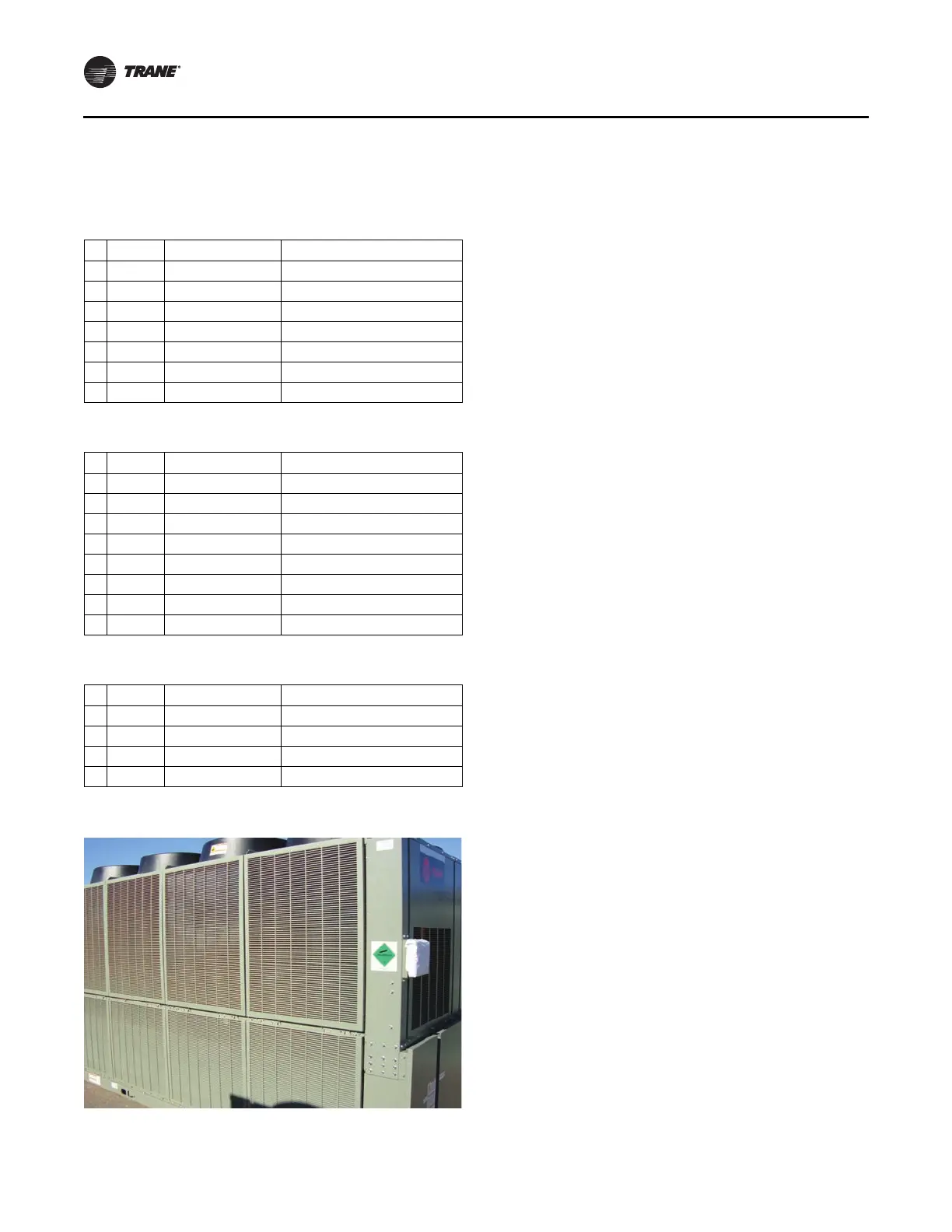

Figure 17. CGAM100–120 ton (W2 units); 1 of 1

Note: Do not use an im

pact gun when installing plastic

louvers.

1. Install three clips (Figure 18, p. 23, Item 2) per upper

louver.

2. Instal

l eight upper louvers (Figure 18, Item 1), four

each side, w

ith provided M8 X 16 sc

rews (Figure 18,

Item 3).

Note: If installing the half louver option, the

instal

lation is complete at this point.

3. Install two louver support angles (Figure 18, Item 4),

on

e each si

de of unit, with provided M8 X 16 screws

(Figure 18, Item 3).

4. Install eight lower louvers (Figure 18, Item 5), four each

side, with provided M8 X 16 screws (Figure 18, Item 3).

5. Install rear louver angle (Figure 18, Item 6) with

provided M8 X 16 screws (Figu

re 18, Item 3).

6. Install lower end louvers (Figure 18, Item 7 and Item 8)

with provided M8 X 16 screws (Figure 18, Item 3).

Loading...

Loading...