PKGP-SVX010A-EN

17

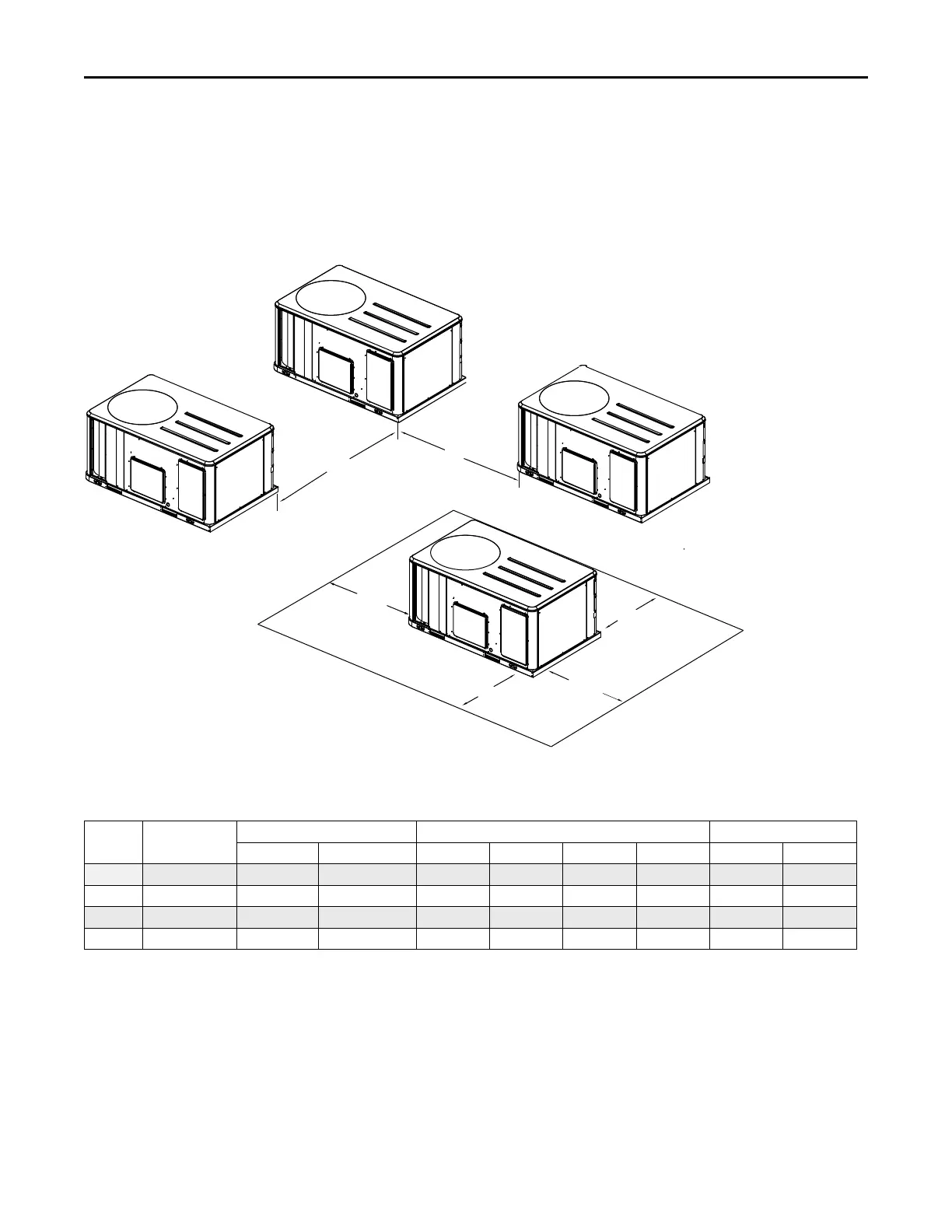

Clearances

Figure 9, p. 17 illustrates the minimum operating and

service clearances for either a single or multiple unit

installation. These clearances are the minimum distances

necessary to assure adequate serviceability, cataloged unit

capacity, and peak operating efficiency. Providing less than

the recommended clearances may result in condenser coil

starvation, “short-circuiting” of exhaust and economizer

airflows, or recirculation of hot condenser air.

Figure 9. Typical installation clearances for single and multiple unit applications

Side by Side

Note 1

End to End

Note 1, 2

7’0”

2134 MM

6’0”

1829 MM

3’0”

914 MM

Single Unit

3’0”

914 MM

3’0”

914 MM

4’0”

1219 MM

Notes:

1. When equipped with economizer

or barometric relief damper, clearance

distance is to be measured from

protruding hood instead of base.

2. Clearance is the same if any unit

is rotated 180 degrees.

4’0”

1219 MM

for D cabinet

5’0”

1525 MM

for D cabinet

5’8” for D cabinet

1727 MM

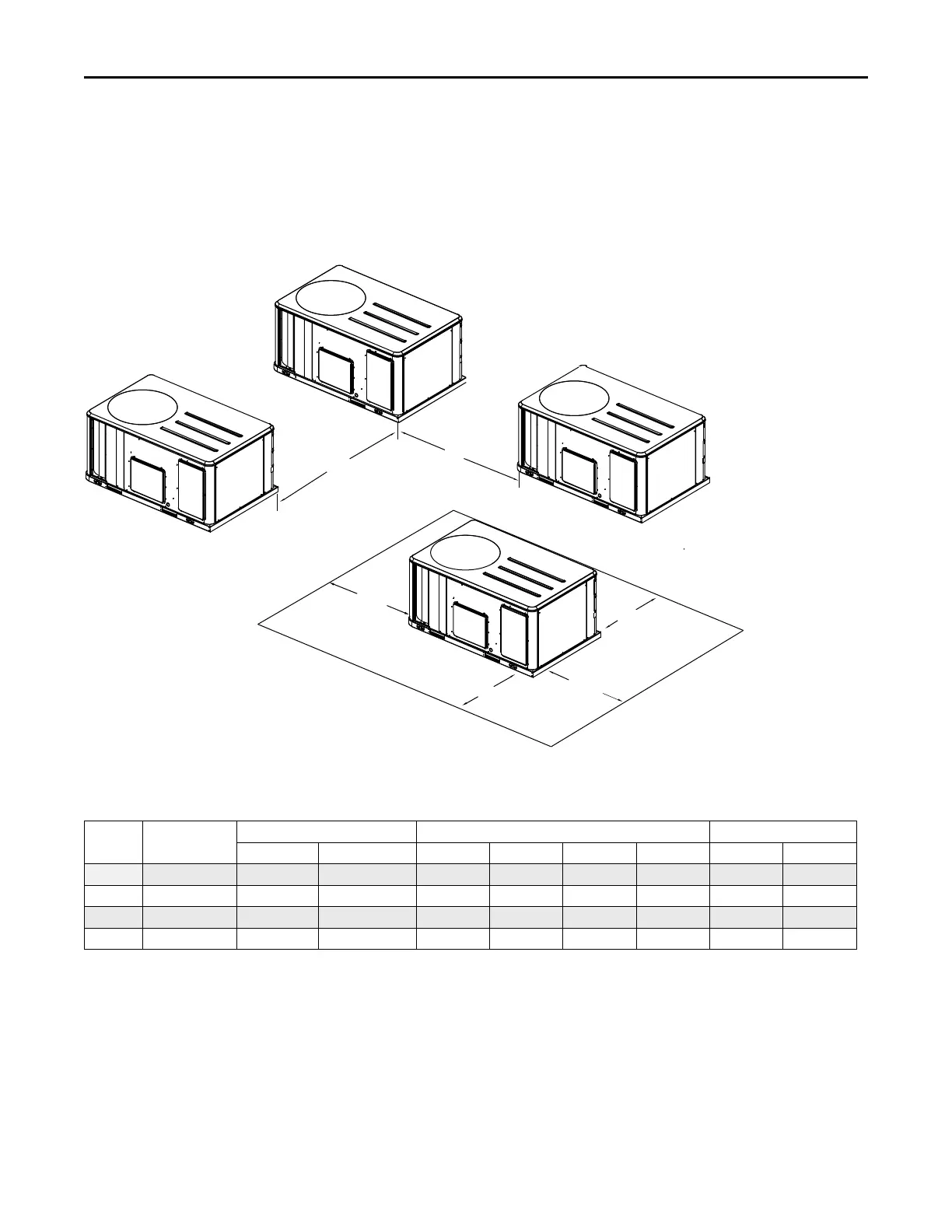

Weights

Table 1. Model weights, corner weights (lbs) and center of gravity dimensions (in.)

Tons Unit Model No.

Model Weights

(a)

Corner Weights

(b)

Center of Gravity (in.)

Shipping

Net A B C D

Length

Width

12.5 WSJ150 2225 2005 688 487 344 486 51 36

15 WSJ180 2246 2026 695 492 348 491 51 36

20 WSJ240 2403 2183 680 550 426 527 55 38

25 WSJ300 2405 2185 680 550 427 528 55 38

(a)

Weights are approximate. Weights do not include additional factory or field installed options/accessories. For option/accessory additional weights to be added to unit weight,

reference the following table.

(b)

Corner weights are given for information only.

Dimensional Data

Loading...

Loading...