Operating Principles

RTAC-SVX01J-EN 107

Condenser and Subcooler

Condenser and subcooler are similar to the condenser

used in RTAA chillers.The heat exchanger consists of 3/8”

tubes that contain refrigerant, large fins that are in the air

flow and fans that draw air through fins. Heat is transferred

from the refrigerant through the tubes and fins to the air.

High pressure gas from the compressor enters the tubes of

the condenser through a distribution header (state 2b). As

refrigerant flows through the tubes, the heat of

compression and cooling load are rejected to the air. In

this process the refrigerant is de-superheated, condensed

(states 2b to 3) and finally subcooled (states 3 to 3b) to a

temperature slightly above the ambient air temperature.

The subcooled liquid refrigerant is collected in the leaving

header where it is transferred to the liquid line (state 3b).

Controls algorithm always runs as many fans as possible

without reducing differential pressure (discharge minus

suction) below setpoint, 60 psid (4.2 bar). If a warm enough

ambient is sensed, all fans will run. If ambient is cooler,

some fans are shut off to maintain pressure differential.

Fan staging depends on chiller load, evaporator pressure,

condenser effectiveness, ambient temperature, and

numbers and sizes of fans installed on circuit.

Algorithm pre-starts fans (based on ambient and water

temperatures) when a circuit starts the compressor. (For

rare conditions such as during some pull-downs, a steady

fan state would either violate the 60 psid (4.2 bar) setpoint

or cause a high pressure cut-out; in those conditions a fan

will cycle on and off.)

For up to two minutes after chiller start-up, the setpoint is

35 psi (2.45 bar) difference, and then before the controls

adjust gradually over half a minute up to 60 psi (4.2 bar).

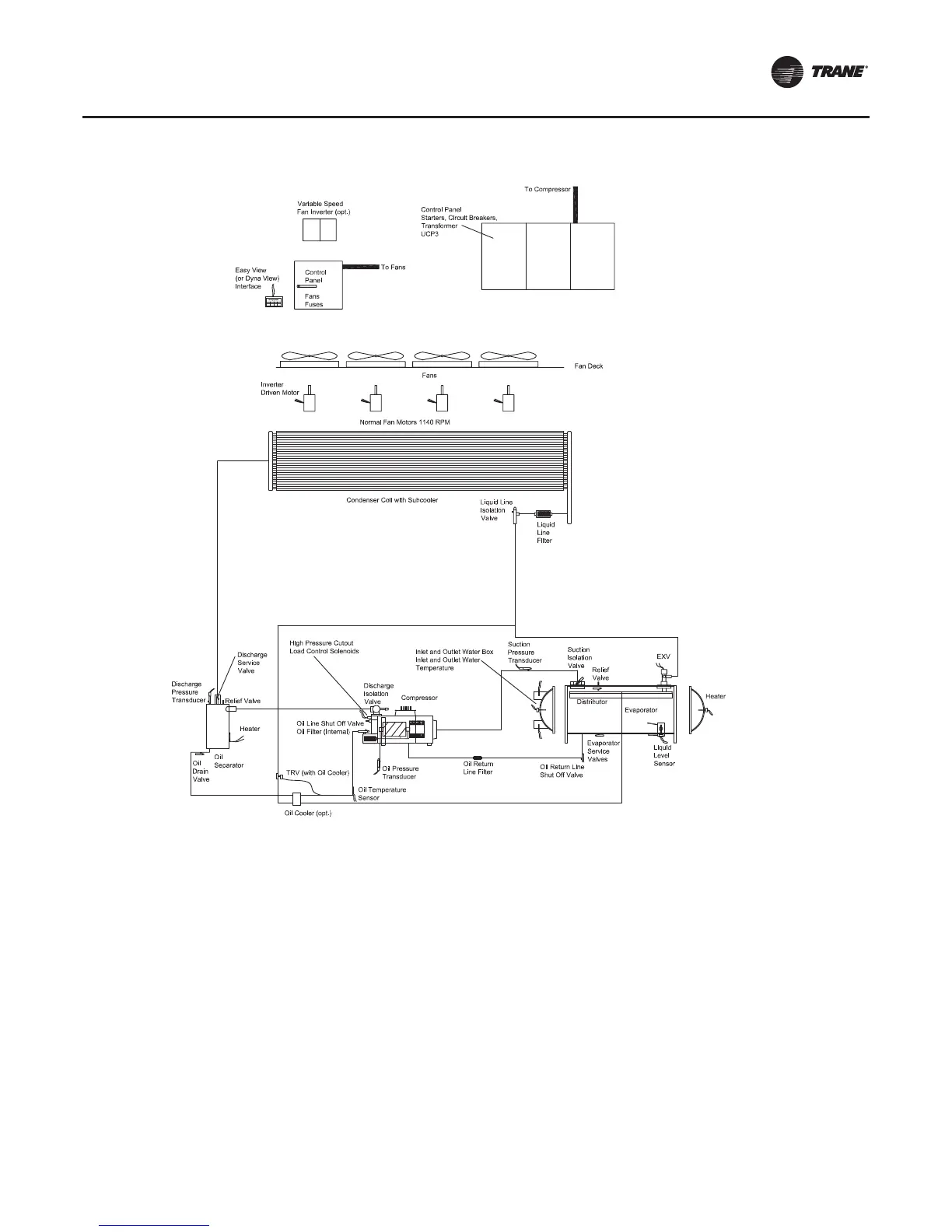

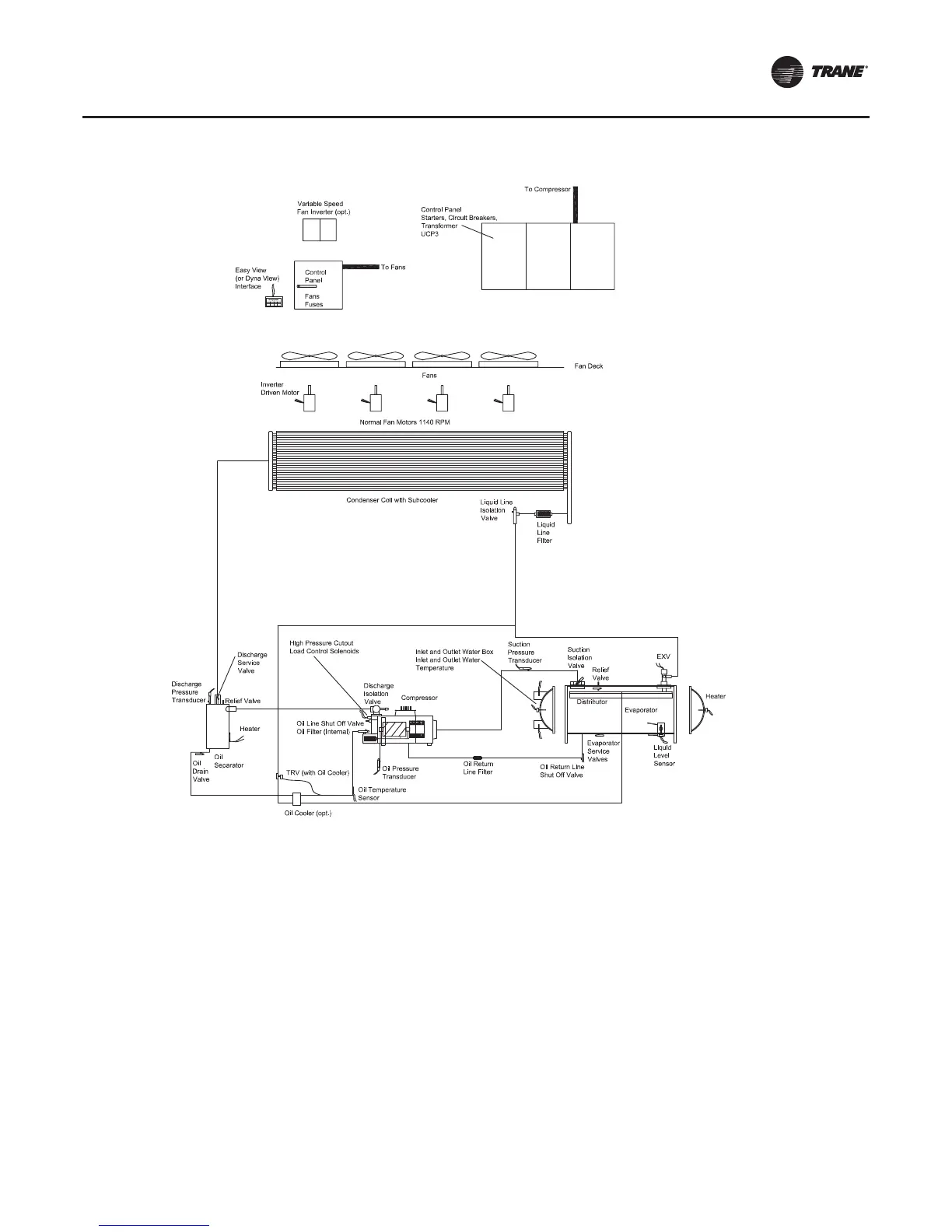

Figure 32. System schematic

Loading...

Loading...