Installation - Mechanical

44 RTAC-SVX01J-EN

Isolation and Sound Emission

The most effective form of isolation is to locate the unit

away from any sound sensitive area. Structurally

transmitted sound can be reduced by elastomeric

vibration eliminators. Spring isolators are not

recommended. Consult an acoustical engineer in critical

sound applications.

For maximum isolation effect, isolate water lines and

electrical

conduit.Wall sleeves and rubber isolated piping

hangers can be used to reduce the sound transmitted

through water piping.To reduce the sound transmitted

through electrical conduit, use flexible electrical conduit.

State and local codes on sound emissions should always

be

considered. Since the environment in which a sound

source is located affects sound pressure, unit placement

must be carefully evaluated. Sound power levels forTrane

air-cooled Series R

®

chillers are available on request.

Unit Isolation and Leveling

For additional reduction of sound and vibration, install the

optional neoprene isolators.

Construct an isolated concrete pad for the unit or provide

concrete footings at the unit mounting points. Mount the

unit directly to the concrete pads or footings.

Level the unit using the base rail as a reference.The unit

must

be level within 1/4-in (6 mm) over the entire length

and width. Use shims as necessary to level the unit.

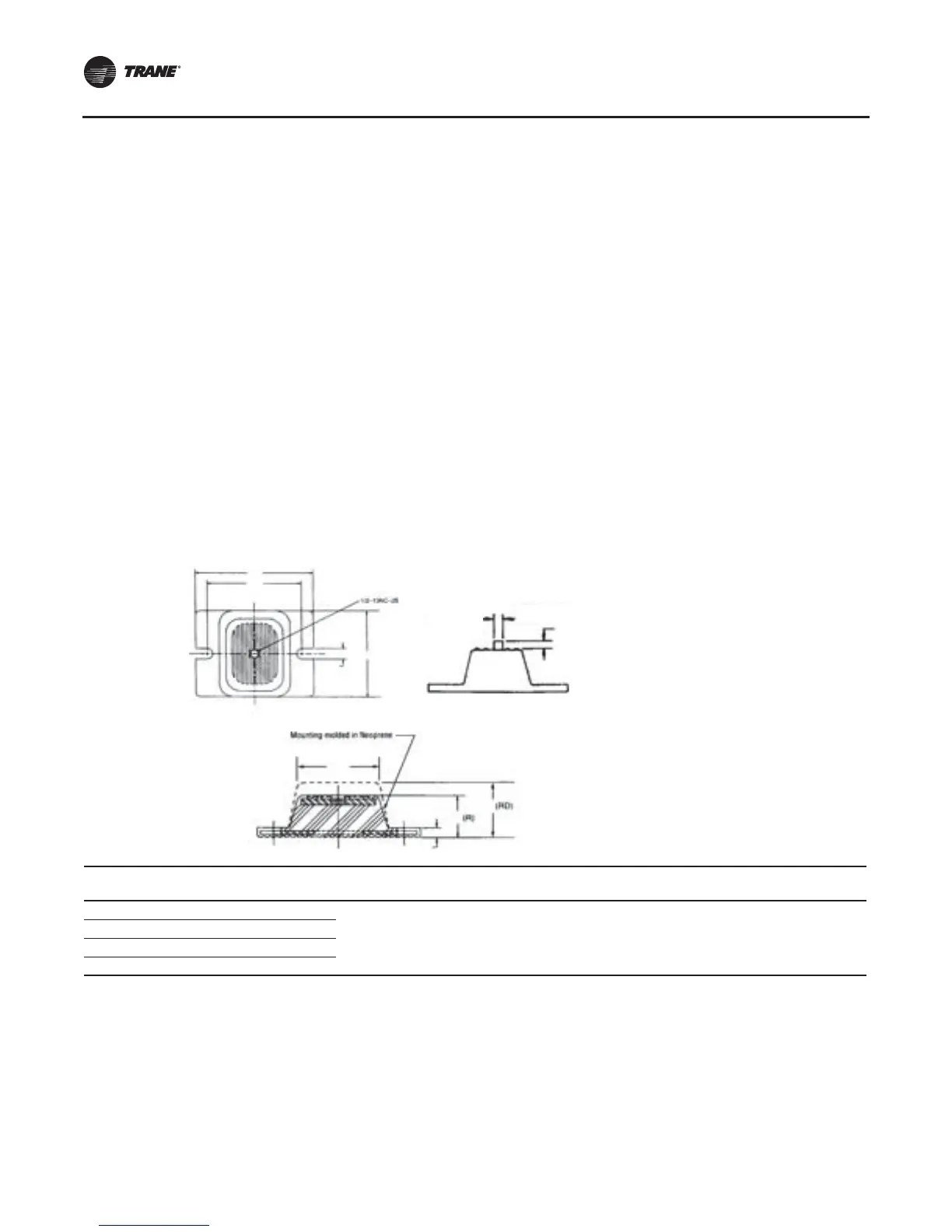

Neoprene Isolator Installation

1. Secure the isolators to the mounting surface using the

mounting slots in the isolator base plate. Do not fully

tighten the isolator mounting bolts at this time.

2. Align the mounting holes in the base of the unit with

the

threaded positioning pins on the top of the

isolators.

3. Lower the unit onto the isolators and secure the

isolator

to the unit with a nut. Maximum isolator

deflection should be 1/4 inch (6 mm).

4. Level the unit carefully. Fully tighten the isolator

mounting

bolts.

EXT

Max Load Each

(lbs) Color

Deflection

(in) A B C D E H L M W Type

61 1500 BROWN

0.50 3.00 0.50 5.00 0.56 0.38 2.75 6.25

1.60±

.25

4.63 RDP-4

62 2250 RED

63 3000 GREEN

64 4000 GRAY

Figure 16. RTAC elastomeric isolator

D

W

L

C

H

H

E

A

« B » Dia

RP/RDP

« M »

Loading...

Loading...